Bamboo Tips - Contraptions Sharpening |

|

< Home < Contraptions < Sharpening

Here are some pictures and/or drawings of sharpeners from various makers. If the name of the submitter is underlined, you can go to the submitter’s web site.

Smithwick, Tom - Leather Sharpening Wheel

Here's a photo of the traveling version of the sharpening wheel. It is by far the fastest way to a really sharp plane blade. Frankly, I don't understand why everyone doesn't do it this way. The diamond paste is necessary for carbide tipped blades, but the honing compound from Woodcraft or Lee Valley is fine for steel blades and cheap. A lump of the compound is in the photo. You can sharpen a steel blade in 30 seconds with this method. Carbide takes a bit longer. If you are only using one type of blade, the tool holder is not necessary, Just clamp a block to the workbench so that the blade leans into the wheel at the right angle. Harry Boyd has a photo at his web site of this setup.

Boyd, Harry - Leather Sharpening System

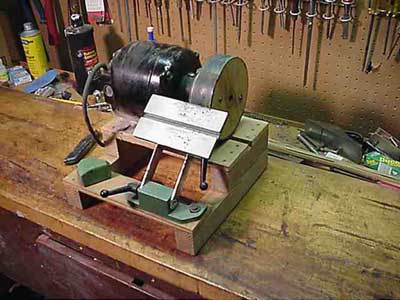

A full view of the first sharpening wheel set-up I built.

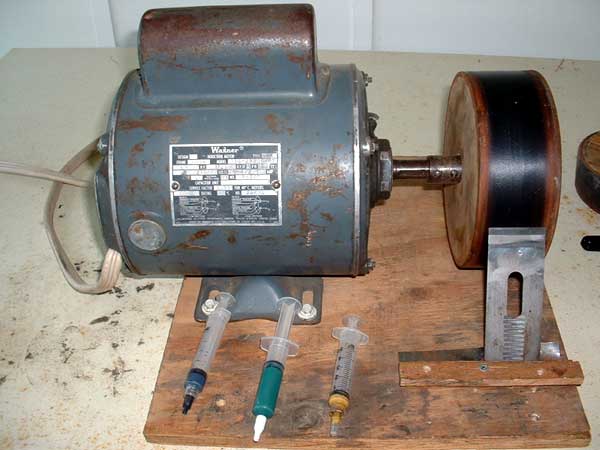

A full view of the second sharpening wheel set-up I built and currently use in my shop.

A closer, end view of the first sharpening wheel showing the blade and stop block set-up.

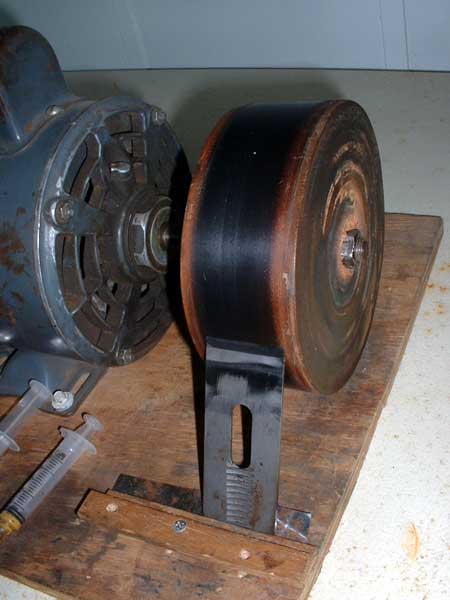

End view of the current sharpening wheel showing the stop blocks.

Motor and arbor without the wheel mounted.

A closer view of the arbor mounted to the motor. Though they do not show in this photo, there are two set screws which fasten the arbor to the motor's shaft.

A Blue, green, and yellow diamond paste compounds in their syringes. I've found the blue too coarse for my tastes. and the green mostly used for intermediate steps.

Green homing compound works great on steel blades, but will not do the job on carbide tipped blades.

Contact cement used to adhere the leather to the wooden wheel.

Because the first wheel I built is not as wide as a plane iron I built the second wheel. You can see the carbide brazed to the tip of this iron.

This wheel is about the right width.

A better view of the stop blocks on the first wheel. I positioned these at first by trial and error, then used screws and glue to keep things in place. One is 35 degrees, the other 40 degrees.

Stop blocks for the wheel I now use. First set the butt of the blade against the block, then slowly lean the bevel of the blade into the turning wheel. Be sure the wheel turns away from you!

Frank Stetzer’s Plane Iron for Grooved Plane

If you use a grooved-sole plane, you only use 1/3 of the plane blade. So why sharpen the whole width every time? I relieve the edges of the blade with a grinder. Makes the sharpening go 3 times faster.

|