Bamboo Tips - Tips Area |

|

< Home < Tips Area < Hardware < Ferrules < Crowning

Is crowning of the ferrule tabs a common practice among most builders? I think they look nice but I have the hands of Thor and always seem to bugger one of the tabs at the very end of the process. Any tips or tricks of the trade you might want to pass on? (again?) (Jon Holland) I don't crown mine. Cosmetically it might add to the look when ulta transparent thread is used on them, but I can see no structural benefit for doing it. (Will Price) I don't crown mine either. I do thin them some though. (Timothy Troester) Crowned and thinned, in that order. I thin them by putting a mandrel inside and using a small file. For crowning I just use a triangular file cutting on the push stroke away form the base of the splints. Occasionally you do get a disaster, you can scrap the ferrule or just glue the broken splint on afterwards so it looks OK. The technical reason for crowning is that the stresses are spread across the half inch or less of the splines and not concentrated as a shear stress across the end of the ferrule metal. I also use slightly thicker thread on the ferrule splints than elsewhere on the rod, its easier. I wonder if Duronze may be worse than Nis for splint breaking as I broke one off my only Duronze ferrule to date. (Robin Haywood) I do crown them, I believe that it helps the transition between the cane and the ferrule. What I do is insert the tail end of a 3 corner needle file and spread the tabs ever so slightly then I use this file to crown the tabs, start out almost with the file laying down and then as you start seeing an angle cut start rocking the file up some. With a little practice you can get the job done in a short time. What I have noticed is that this also helps with the thread not cracking where the ferrule ends and the cane starts. This is what works for me but certainly not the only way to do it. (Joe Arguello) Do you also thin the tabs towards the tips and if so do you do it before or after cutting the crowns. (Larry Puckett) I do thin the crowns but I do it after I glue the ferrules on the blank! What I do is crown the tabs, debur them and make sure the ferrules are clean inside. Then I glue the ferrule onto the blank and tie them down with some thread as in binding thread. When they are dry I am very careful not to flex the section so as not to break them free. I then use the small 3 corner file and thin them down and feather them to the blank, now wrap them. Hope this makes sense and helps. (Joe Arguello) Wayne's book tells how to do it with a strip of sandpaper tacked to the workbench. (Neil Savage) The easiest way to do this is with your Dremel and a small fine diamond cut of disk. It takes 5 minutes. This sort of thing. (Gary Nicholson) I really must get myself a Dremel! (Robin Haywood) I do it with a three cornered jewelers file. (Dave Norling) I also crown my ferrules to improve the transition of structure between the ferrule and bamboo. It is my technical opinion that one wants as smooth transition of the EI modulus through the ferrule to the bamboo, and also to minimize local edge stress where the ferrule and bamboo meet. I also thin the ends of the crowned ferrules after the crowning on my lathe using a very low speed and very fine sand paper (1000 grit) and before assembling them on the prepared bamboo. (Frank Paul) Forgive my ignorance, but what is crowning on a ferrule? I'm new to rodmaking and following the ferrule links with great interest, as I want to learn to make them on my lathe (also a newbie at machining). (Chuck Pickering) Thanks for asking. Have a look at this picture:

Those ferrule tabs have been formed into a shape that resembles a crown. Those particular ferrule tabs are overwrapped with white silk, which becomes transparent when finish is applied. (Harry Boyd)

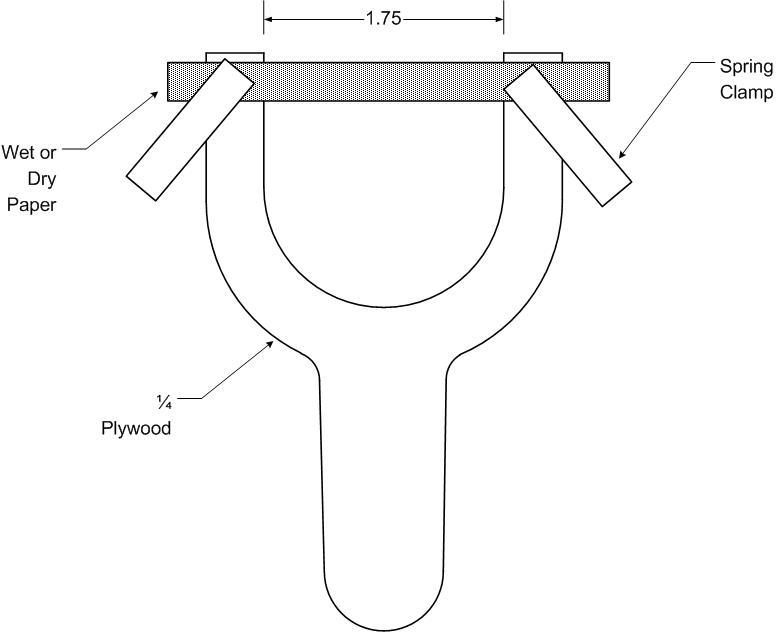

To all who sandpaper ferrule crowns: Last week, I think, there was some discussion on crowning ferrules. Well, I used to use Cattanach’s technique trying to hold sandpaper strips in the fingers of one hand while manipulating the ferrules in the other. Needless to say, trying to hold a small strip of sandpaper in the fingers of you left hand (apologies to you southpaws) is nearly and impossibility so here is a link to a drawing of a simple tool I made to hold the sandpaper strips. The first time I used it I nearly wet myself. It made the job so easy it was almost a pleasure. (Al Baldauski)

I just put one end of the strip in my vise and hold the other tight with my left hand and slide the ferrule along the strip with my right hand. It works just fine. (Hal Manas) You can also tack one end of the strip of sandpaper to the workbench. Of course, us toyl junkies.... (Neil Savage) Where did you get the clamps and brand name if possible. I know that this is exactly what I need but I can’t seem to find small clamps that will hold. (Ren Monllor) Tony Spezio had a nice little gadget in a recent Power Fiber article that I'm going to build. I built a rod and the owner wants an extra tip now so I need something to give him so that he can fit the ferrule on the new tip himself. Hopefully Tony's gadget will do the trick. It's a small clamping block with a hole drilled in it that also holds a piece of sandpaper that you can tighten up on the ferrule with a couple of spring loaded wing nuts. Then you just turn it by hand to sand the ferrule. (Ken Paterson) Your idea looks very interesting - looks like an old sling shot device. What I have been doing is using two fine machinists files - one triangular in size with a 30 degree angle on the cutting edges and small; and a shallow 10 degree angle file that is about 1 inch wide with angles on two sides (4 cutting surfaces). I use the smaller file to start the cuts in the slots and finish the work with the smaller angle file. This seems to work fairly well for me as I hold the ferrules by hand. I do tape the ferrules so that I do not score the "good" part while doing my file work. Just another idea. (Frank Paul) I start my crowns with a file and finish with sandpaper. The sandpaper gives a finer finish and is less aggressive so I don't slip or overdue it near the end of the process. (Al Baldauski)

I have just crowned 2 sets of ferrules for rods that I finished (it took several hours) and have done so since I started building rods, but I am wondering if I need too. I have seen old rod that don’t even have slits in the ferrules and some with but aren’t crowned and they look fine. I know it is supposed to relieve some stress and keep the finish from cracking around the base, but some of mine still have cracked and it does have a nice look. So how many of you crown and how many don't? If so maybee some other reason why, and if not Why? and do you see and problems. (Rick Barbato) I crown my ferrules and taper the tabs to a rounded triangular shape. I believe in provides stress relief at the ferrule-bamboo interface and helps to prevent excessive shear stress at the ferrule-bamboo joint where the rod flexing transition occurs. I have had very few wrap-varnish stress cracks at the ferrule-bamboo interface. A flexible tung oil based varnish is also important for the ferrule wraps as a hard varnish that is hard/rigid has a higher tendency to crack. Just my experience and opinion. (Frank Paul) I started cranking up the thread tension when I get to the tabs. That seems to help, but not totally convinced. That was interesting what you said about the varnish. I've been wanting to try shellac, but concerned about it being too hard and if it might crack. Any thoughts on shellac?? I crown my ferrule tabs and place them on the flats. seems to fit better. (David Dziadosz) I'm a "don't." Payne didn't, Leonard didn't, Heddon didn't and as far as I can tell from the pictures of his rods I've seen, Dickerson didn't, that's enough for me. (John Channer)

How many people crown their ferrules, and how many do not? I have done it both ways, and to be perfectly truthful, have never yet had a problem with not crowning. Certainly it is more difficult to fit ferrule to blank with a smooth transition if you don't crown, but it does, to my eye, look neater once done. How about the masters of the golden age Crowned or not? Present age? One of those questions, I guess, to which there is no real answer. (Peter McKean) I've seen a couple of old rods and drawings of old rods that had crowned ferrules, but it was the Victorian era, they were into lots of decoration then. I don't and have never felt the urge, it's not one of the things I feel is important. (John Channer) Sometimes I crown and sometimes I don't. My criteria for crowning generally is based on the thread I use. If I use a light or clear wrap that allows the crowning to show, then I will crown them. If it is a dark color such as Java beige which turns a very dark translucent color(about like root beer) or if the threads are to be color preserved and remain opaque, then I don't crown. Why waste the extra time and work when it can't be seen. I'm of the opinion right or wrong, that crowning is cosmetic only and has nothing to do with making a better rod. I've restored 2 rods by E.W. Edwards and the ferrule tabs were almost paper thin where they met the blank, but they were not crowned. I've never seen a Dickerson with crowned ferrules. In fact most of the classic high end rods that I have handled did not have the ferrules crowned. When I do crown the point goes on the flat. I have seen a lot of crowned ferrules that were made by modern makers that aligned the points with the apexes. I don’t because I believe that the rod will flex better with the apex lined up with the slots and the wider tab portion with the flats. That's just my opinion though. If any scientific study has been done that proves that crowning is better or that one alignment method is better than the other, I'm not aware of it. (Will Price) Can't add a lot, those who have done a lot of restorations would know better. But, by inspection:

Garrison emphasizes his priority for the feathered ends to be across the corners, with the slits on the middle of the flats, giving added protection to the glue lines at a point where the stresses are very high. I also note that these older makers by no means used Gossamer, but more like Belding/Corticelli size B silks for the ferrules that is thicker than Naples, although by Garrison they were using more modern glues but still looking to protect the sections. I note also that several manufacturers double wrap silk at ferrules, and Winston also double wraps somewhat at the guides. Because of this and some use of color preservers, I can't always see what the ferrule is like. (Sean McSharry) I read somewhere (can't recall exactly where....may have been on Clark's) that crowning and thinning the metal at the crowns adds a bit of flexibility in the area where the cane enters the ferrule. This supposedly has the benefits of helping to prevent the varnish on the threads cracking but also due to added flexibility in the area reduces the likelyhood of having cane failure at the ferrule. I guess it also may impart a bit more "action" in the area of the ferrule which ordinarily is a dead spot. (Norm Knieriem) I don't crown although I do feather the tabs and mount the ferrules with the tabs to flats. I've noticed that I don't get cracking @ the tab/cane junction with exception of 2 rods. One is where I chose a lousy glue application and the other was glued with hot melt glue way back when. I double the wrap on the cane and then a single wrap on the ferrule. Seems to work OK. Been doing it this way for the last 150 rods. (Don Anderson)

Anyone have any good directions on crowning ferrules? My first failed attempt at crowning was this evening and what seemed like a simple process didn't work out as such. I have a small triangular file but something just doesn't click. (John Smith) When I crown tabs, (I don’t always), I use a set of Jeweler’s Files. Mostly the knife edge file but also the slim triangular file. It’s not easy to get them all uniform. (Larry Swearingen) I place the ferrule in the groove on my roughing form and hold that sucker down with my thumb. I use a small triangular file and start the crown by filing the slits from the inside first, then finish from the outside. After shaping with the file, I use 400 grit sandpaper to Clean up the crown. Clamp one end of the paper in a vise and hold the other end, much more control this way. After completion, I place a tapered wooden plug sized to fit the in the ferrule in the mouth of the ferrule and chuck the ferrule in my lathe and thin and polish the tabs with 400 grit followed by 1000 grit. I case no one else warns you, sooner or later, you will ruin a ferrule or two by thinning the tabs too much. Just part of learning. (David Atchison) I start by thinning the tabs with 400 grit. The ferrule is on an appropriate sized drill bit base and the cutting portion mounted in a three jaw chuck. After thinning I make a number of 320 and 400 grit 1"x8-10" strips. I pin the strips to the workbench and starting with the 400 insert the two opposing tab slits and run the ferrule back and forth, counting the number of runs and moving on to the next two slits repeating the process and making sure that each set of slits is evenly sanded. Move on to the next set of slits etc. The strips will need to be changed frequently as the sides fray. When the slits are large enough to allow the 320 to easily slip in I repeat the process slightly angling the ferrule to get the appropriate taper to each point of the crown. Finish with the 400. A little time consuming but I have had good luck with this method and its one of the few steps I have yet to screw up. (Bob Ratcheson) For 100 rods or so, I carefully crowned my ferrules; I did it by cutting long thin ribbons of fairly fine wet and dry sandpaper, inserting them across the diameter of the ferrule, and sanding with a back-and-forth motion, changing position frequently, and progressing down to about 2000 grit to finish up. At which stage I had a long hard critical think about the whole business and decided there was no advantage to the crowning process, so I just stopped doing it. I still feather the tab ends down to very thin, but that is a cosmetic thing. I think that crowning is also a cosmetic thing, so if you like the look of it, go ahead and crown. I prefer the clean look of the ferrule un-crowned, so I don't do it. I just cannot convince myself that I am likely to increase ferrule flexibility significantly by crowning as compared with just cutting tabs, and I certainly don't get any more rods broken through not crowning! It seems to me that broken sections at the ferrules are caused by flaws - in the bamboo itself, in the builder’s technique, in the rod design and in the standard of casting ability of the user. The last two or three breaks I can recall were pretty well all caused by the angler's trying to jerk a fly loose from trees or weeds by using the rod. I should add to what I said before; they are broken not only by flaws, but also by jerks! (Peter McKean) I also used to crown ferrules but don’t anymore. In Ray Goulds ‘Tips and Tapers’ (I think) he refers to a dremel bit for crowning. I unfortunately don’t have the spec with me right now. It works very well to establish the crown and then you can finish off easily with sandpaper strips. I used to simply wrap a good few layers of tape around the ferrule and then hold it firmly (but not too firmly!) in a vice to work on with the dremel. (Stephen Dugmore) I crown my ferrule tabs by putting a thin strip of 400 sandpaper - usually aluminum oxide - in my vise and just put the strip through opposing tabs and pull it while rotating to the end of the tab. I change to 600 paper or higher when I get them close to what I want. I started doing this after I saw a beautiful rod at Greyrock in 2003 that had impossibly clear wraps over beautifully crowned tabs. I like transparent wraps, but I have never gotten them that clear. After reading this group of posts I may go back to not crowning the tabs. (Hal Manas) I have not worked on anywhere near the rods that most of you have. But I have both crowned my ferrules and not crowned them (I always feather the tabs though). I haven't had any structural problems with the bamboo either way. The Dremel bit that Steve referred to from Ray Gould's book is #7120 (make sure your collet will fit the shaft; the Dremel Collet Nut Kit #4485 should cover everything). My experience with the Diamond Point #7120 is that it does fast but very rough removal of the nickel silver on the tabs. I then follow it up with sandpaper like Steve and Peter. (Chuck Mercier) I used to use sandpaper strips as in Cattanach's video but it took a while and I always got hand cramps but the crowns did look great. Now I use a small jewelers knife file I got from riogrande.com and you can easily crown a ferrel in 5 minutes. You have excellent control this way and won't take off to much or mess up the ferrule. It helps to get a handle to go with the file. (Ron Kubica) Dremel bit. (Ralph Tuttle) The one that Ray used was the diamond version of that, #7120. I use a small rotary tool (http://www.harborfreight.com/80-piece-rotary-tool-kit-68986.html) I got from Harbor Freight with 220 grit Dremel sanding disks on an arbor. Since they are abrasive only on one side, they don't go anything to the tab adjacent to the one you are working on which is good. I have an article on a ferrule slitting setup I use on my web site. Down at the end of it is a picture or the crowning tool setup. (Mike McGuire) FYI-Got my dremel diamond bit #7120 from Home Depot. Last a long time & does a good job. (Don Schneider)

What is the best way to crown the ferrules? I usually leave them because it is a pain. Any help always appreciated. (Craig Dinsdale) I usually slip the ferrule on a drill bit backwards with the ferrule on the butt end, either 10/64' 13/64' etc. put the drill bit in the drill backwards and use 400 or 600 wet/dry paper on the "slit" ends until, they’re paper thin. Then, I use 400 WD paper in between the slits to widen them slightly and then a fine jeweler's file to "crown" the tabs slightly. After that it's on the drill bit one more time to take out scratches on the tabs & fine steel wool to polish things up.... Just finished this exact method today and it worked nicely... (Al Redlhammer)

|