Bamboo Tips - Tips Area |

|

< Home < Tips Area < Hardware < Ferrules < Stepdowns

I am building a Payne 98. I took the taper from George Maurer’s book and in it he suggests taking an average of the two stations that come before and after the ferrule and using that figure to lessen the drop over the ferrule station. He suggests this is to accommodate the new ferrules vs. the step downs that were used on the original taper. My question is this. Why not just use step-downs? The higher cost of the reproductions and the pain in the a** of fitting them seems to pale in comparison to the fact that the action may be altered if I DID NOT use step downs. I suck at math beyond algebra and my understanding of the engineering in rods is basic as best, but my guts tell me the action would be changed if I used Swiss ferrules. What is the collective experience of you wonderful folks? (Eamon Lee) I don't like step down ferrules, so what I do is size the flats dimension of the butt section for standard ferrules, I'll usually wind up just taking the corners off on the tips slightly. This way you can use Swiss style ferrules and not loose the intended action. I do this a lot on Dickerson tapers, most of which seem to have some drop over the ferrule. (John Channer) Use a Leonard type ferrule or you WILL change the action of the rod. the 'drop' over the ferrule station was one of the key things that was designed into the rod at the time. you can use the step down ferrules from CSE and they are the same cost as the Swiss type. the cross section of the Swiss ferrule is much larger than the Leonard type and that makes the ferrule stiffer than it was supposed to be. in addition the Swiss ferrules are too short. a ferrule is NOT a 'hard point' in the taper, they do flex. indeed they are stiffer but they are not rigid. step ferrules are sized EXACTLY THE SAME as a Swiss ferrule. if you buy a 12 it is 12/64 on the female and the male side with the exception that there is a 10/64 cut to make for the slide portion of the ferrule. all of this is the same info that I have written before. The archives are maybe 5 years old tops whereas the Leonard ferrule in its modern form is over a hundred and the Swiss in its modern form is about half that. we are not trying to find the fission cross section of a new element here. One enduring question that keeps nagging at me , with a group that by and large fusses over whether their varnish brush is made from the correct left leaning hairs off of a south facing bulls ass why are so many unconcerned with the changes that are wrought by disturbing an important aspect of rod design merely to use a ferrule that is easier to fit to the rod? (AJ Thramer) Point well taken. I've marveled at how much the elimination of this drop on the Paynes and Dickersons changes the actions. It makes them a different rod. (John Zimny) An interesting 'exercise' that would illustrate what AJ is pointing to would be to run the dimensions in one of the taper programs and visually see how the curve is affected by the differing ferrules. (Wayne Cattanach) Well stated [:-)] . I have a few questions: 1) Does anyone have the ferrules specifications for step downs? 2) Doesn't the step down magnify the wave linear action through the ferrule thus creating a much faster tip section and increasing stress throughout the entire tip section? 3) Doesn't the step down create a huge stress concentration at the location of ferrule? 4) My understanding was that 2) and 3) reduced the operating life of tip sections, and this is the reason Super Z's were developed? (Kyle Druey) I think the super Z was originally designed to go on the early fiberglass rods, which, of course, cannot be necked down. I read an article somewhere by Louis Fierabend which credits Garrison with being the person who first used them on cane, just as Carmichael claims in the book. (Tom Smithwick)

I am going to be building a Leonard taper rod and had a question with regard to step-down ferrules. I have never used them before and would like to use them for this one. However I am not familiar with the size difference, compared to super Swiss ferrules. Are they the same? ie; is an 11/64ths super Swiss the same as an 11/64th step down? Or do you further have to compensate and remove more material of the blank for the step down? Also is it worth the extra expense to buy the step down ferrules that are replica's of the Leonard and Payne era, or are the Super Step Downs just as nice? (Robert Cristant) 11/64th step-down is the same as 11/64th Swiss except more material will have to be removed at the male slide. The Super Step Downs are just as good as the Leonard/Payne replicas. (Marty DeSapio)

What is a step down ferrule and when should you use one? Is the step 1/64? I'm looking at building a Dickerson 7012 and I'm not sure if this taper calls for (or should/shouldn't use) a step down ferrule. The end of the tip (@ 42") is .176 and the beginning of the butt (@ 42) is .188. If I build this rod I thought that I would just need a regular 12/64 ferrule. Also, how does a step down or no step ferrule affect the action of the rod? (Mark Pohl) The step or Leonard ferrule- the female is sized to the rod just as a Swiss would be, the male, instead of mating with an oversize barrel on the female is reduced in diameter to fit into a female that is a straight tube, concerning the interior measurements about 60% of the length of the male is reduced in diameter by 2/64 and the remaining 40% or so is the same diameter as the female tube. So, it is easier to fit a rod that has a drop across the ferrule but there is no reason to use them only on that type of rod as the dimensions are the same. The downside - they take longer to turn a ferrule station. Upside - they look better. The Swiss ferrules are looking pretty clunky these days. The argument that the Leonard ferrules are not as strong is pure BS. The 1-685 Gillum takes a custom ferrule. A straight tube female and a straight tube male. (AJ Thramer)

I haven't used step down ferrules before, but now I need a set for a Dickerson 6010 I'm working on. The tip of the butt dimension is .171 and the butt of the tip is .155. I ordered a size 11 from Golden Witch, but the collar of the male ferrule is bigger than the dimension of the butt of the tip .155. Should I have ordered a size 10? Should I be removing bamboo from both sections to install the ferrules? (Scott Grady) I'm no expert on step-downs, but it seems that those restorations I've done had both the male and female ferrule stations cut down. Obviously the male slide is cut down quite a bit more than the rest. I've used a few step-downs, and really like the way they look. More than the appearance, I think I like the extra "kick" one feels when casting a rod with a slight drop from the female to the male. I've just finished a couple of rods loosely based on the Dickerson 8015, and they had about a .010" drop from the upper end of the female ferrule station to the lower end of the male. I did cut both stations down to almost round in order to insure a good cane to ferrule fit. (Harry Boyd)

I'm about to start work on my third rod. As I am looking through a few tapers I see references to step down ferrules. How does one determine if a step down ferrule is required, and is there any advantage or disadvantage to their use. If there is no advantage, would one be better off just using a normal ferrule? (Jim Brandt) You can identify step-down designs easily- they are the tapers that have a 1/64 inch drop at the ferrule station (0.015 in), and sometimes even more. Step-downs are thought to impart a livelier action to the rod, and make the rod action feel lighter. They look nice, and some people believe that the Super-Swiss style ferrules look clunky. Step down ferrules are more difficult to fit, and some makers believe they are weaker than the Super Swiss ferrules. The weakness issue is an unresolved controversy, and you will find strong proponents on either side. Many, many rods needing step down ferrules have been modified to use Super Swiss by building up dimensions of the tip section so the diameters are identical at the ferrule station. This again is a complex issue, some makers believe that a classic taper is ruined by doing this, others do it routinely. My experience with step downs is limited - I have used them, but most of my rods have been made with Super Swiss style ferrules. In cases where I altered a step down taper in order to use a Super Swiss, I began beefing up the tip section at the second or third ferrule station down the rod to eliminate sudden jumps in rod diameter. I did a couple of Payne tapers that way, and they may not be original, but they cast great. And I actually liked them a bit better than the Payne I just finished with step-down. Ultimately, you need to try both ferrule types and decide for yourself what you like better ... (Jeff Schaeffer)

I've finally come to a point where my lack of understanding of the "step-down" ferrule can no longer be ignored. I was aware that Dickerson used them and also that they were available, so I just built two 7613s using his tapers with the intention of buying some step-downs to account for the .014 drop from tip to butt. The rods are built and I just got back from Golden Witch with the knowledge that whatever they have for my use, it doesn't do what I need. My problem is that the tip ends with a .198 diameter and the butt "begins" with a .213 diameter I thought the ferrule would somehow allow for this discrepancy in its metal, but the step-downs that Russ had ( except for what he referred to as a "Classic step-down", and looked rather bizarre) possessed the identical ID for the cane on male and female pieces. Is there anyone who makes what I understood to be a step-down, or was I so mistaken that I'm now left with several equally unacceptable alternatives to bring the ends of the sections into agreement??? (Art Port) Consider building up the tip ferrule station with slips of bamboo as is done on a lot of British rods. Alternatively, have a set of replica ferrules made. There are several people on the list who do this kind of work. Dave LeClair has made replica ferrules for me and did a good job at reasonable cost. (Ted Knott) Tony Larson makes Step Down ferrules. (Danny Twang)

I just don't quite understand the step-down thing. I see Bob Nunley asked about a table of sizes similar to the one in Garrison's book for Super Z ferrules, but I didn't see any answer. Does such a thing exist? If so, I'd like a copy or a web address or some other pointer to it please. (Neil Savage) I second that. I asked the same question some time ago and I ended with the attached Excel file. It would be helpful for my understanding, if someone who know the step-down-thing could make a little drawing of the ferule according to the numbers on the sheet. Thanks. (Markus Rohrbach) I like this for the most part.

Personally, I am a huge fan of step down ferrules and the original rods designed for them. I have made the same rod with Super Zs and not been as happy. Obviously, some rods were designed for the Super Zs and I would use one in those cases. (Bob Maulucci)

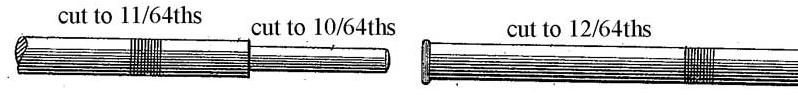

I have a newbie question here in regard to Step Downs and SuperZ's. When they are sized at a joint (say a 2 piece rod), does one use the same size ferrules on the rod? Are 12 SD's the same as 12 Super Z's for geometric fitting to the bamboo? (Frank Paul) As you can imagine, it's important to talk apples and apples rather than apples and oranges. From Classic Sporting Enterprises I have used Super Swiss (modeled after the Super Z), Super Swiss Truncated, and one of their two step-down offerings. I think the step-downs are called Super SD. In any of the three ferrules one would use the exact same size. The inside diameter of the male and female are the same. Of course on the Super Swiss, the diameter is uniform. On the Super SD, the male ID is in two steps, one 1/32" smaller than the other. Classic Sporting Enterprises offers another step down which I have not used. The literature implies that the male ID is smaller than the female ID. I've also used both Swiss style and step-down ferrules from Tony Larson. The Swiss style are somewhat shorter than Classic Sporting Enterprises, and the ID is the same for both male and female. In Tony's step downs, the male ID is smaller than the female ID. At least on the ones I used. I'm not aware of other quality step-down ferrules which are available on even a semi-commercial basis, unless AJ Thramer offers them. (Harry Boyd) In a size 12 step down (at least in the ones I have), the female ferrule station would be cut to 12. The inside of the male would be cut to 11 and 10/64ths. (Bob Maulucci) Lou Fierabend designed the first Super Z. I quote from Garrison: The Super Z ferrule was the only ferrule ever marketed that was, from an engineering standpoint, stronger than the rod section itself. The ferrule allowed for "continuous action" through the rod sections. I agree with the Master on this point at least. Step-downs may be fine for reproductions, but seem to fall short technically. (Bill Fink)

A while ago, I saw the following fly by my screen: Bob Nunley writes: "on my tapers, I now exclusively use step-down ferrules... I think Mr. Payne had it going on and knew what he was doing better than most, so followed his philosophy on tapers and ferrules..." And Bob Maulucci writes: "Personally, I am a huge fan of step down ferrules and the original rods designed for them. " Which begs the question: What is it about step-down ferrules that make them so desirable? If I look at a conventional Super Swiss or SuperZ Vs. a step-down, looks to me like the step-down has more metal over a longer length. More metal = more weight, no? And the longer length of metal would seem to make for a longer stiff spot, and more of a discontinuity in the rod's bending/stress curve. Really trying to wrap my brain around this step-down business. If I look at it from an "intuitive" standpoint, the notion of introducing a deliberate, sharp step in an otherwise relatively smooth taper makes no sense. I'm sure there's a reason for it, but I've not seen a good discussion on exactly what those reasons are. When two guys like Nunley and Maulucci give such strong endorsements as above, I tend to take some notice. Thus the conflict -- one side of the brain says "Hmm... must be something to these step-down ferrules", and the other side says "too heavy... too bulky... why would you put a step in a perfectly smooth taper... etc., etc...". I'm certainly willing to be illuminated, as, I'm sure, are at least a few lurkers out there following along. :-) So, step-down fans, let's hear the whys and wherefores as to why one would want to use a step-down in the first place. (Todd Enders) Just my 2 cents: THEY LOOK GREAT! Not to mention that the tapers of Leonard, Payne, Gillum, etc. all used Step Downs. If you are trying to mimic these tapers then you should use step downs. They are just a much sleeker ferrule. I have been using them exclusively (unless the taper called for a Super Z style) for 5 years and have not had a ferrule problem at all on any of my personal rods or those that I have built for others. (Robert Cristant) Maybe yes, maybe no. I am pretty sure more than a few rods based on Payne/Leonard/Gillum/Thomas/et al tapers have been made by others with SuperZ or Super Swiss ferrules, and the casting characteristics of same probably please their respective owners and makers. Other than aesthetics and tradition, nobody has said why one would want to use a step-down in the first place, or why one would want to design a taper incorporating them. Some folks really brag them up, and there's got to be a reason for that aside from looks. And, I'm certainly not saying don't use step-downs, if that's your pleasure! If you like the looks of them, and/or want to stay faithful to the way the old masters rendered their rods, good on ya, I say. On the other hand, if you're going to make performance claims about step-downs and tapers designed to use them, it also rather behooves you to present some technical justification for that position. In the improved performance case, the fact that Payne, et al, did it back in the day really doesn't quite feed the bulldog. Kinda like celebrity endorsements... I'm trying to keep an open mind here, and am more than willing to be convinced (or told that I'm full of crap... :-) . I look at a step-down, and a Swiss or SuperZ, and weigh their relative merits as I see them. They're all bits of metal that join bits of cane together. There's some difference in weight, length, engagement surface area, etc., which will have some impact on the rod action. If we leave the SuperZ out for the moment, and compare the Swiss and the step-down, it almost seems to me like any perceptible difference in casting character imparted by the difference in ferrules may be in the eye of the beholder. Much like audiophiles arguing over whether gold-plated connectors sound "better" than nickel-plated ones. To 99 & 44/100% of listeners, IMHO, any difference is between the ears. Indeed, with the way some of the old masters tweaked their tapers at intervals during the production lifetime of same, plus the looser tolerances worked to back then, I would suspect any variation in casting characteristics due to ferrules alone could be overwhelmed by taper revisions and/or production variances. No doubt, I'm kicking a few people's sacred cows. Certainly not my intent! Just a tyro rodmaker who sometimes wants to know why others do things the way they do (especially if they claim a "better" way). (Todd Enders) In my experience what step-downs do primarily is provide backbone to a taper. You can wind up with true dual rated rods because of the step-down and you can wind up with a rod that feels like it has more reserve power when cast because there is quite simply more cane behind the arc of the rod after it flexes past the ferrule. When you remove the step-down and smooth out the transition it takes out that feeling of reserve power. Just my humble opinion and limited experience, for what its worth. (Bill Walters) Thanks Bill, this makes some sense. In further digging, I've also seen it stated "as the drop makes the action faster". It's perhaps more than a simple speeding up of the action though, since the increase in taper occurs as a jump, instead of being smooth. Which brings up a thought as far as using Swiss or SuperZ ferrules on a taper originally designed for step downs. Why smooth the transition? Why not do it in the cane instead, ALA a swelled butt? Take the drop and move it back onto the butt, back behind the ferrule station. Then, you'd have the butt side ferrule station same sized as the tip. Or, conversely, move the drop forward, ahead of the tip ferrule station, and have that station the same size as the butt station. From a stress/structural standpoint, this may be the better option of the two. The drop wouldn't be as sharp, and would depend on your forms and ingenuity, but I should think you'd get a similar effect. The relative "speed up" of the action probably compensates to a degree for the added weight of step-downs in a 3-piece rod, and allows you to get away with using them vs. truncated Swiss ferrules. At least that's what I'm thinking. Again, it's entirely possible that I'm full of crap here. Would be an interesting experiment to build 3-4 rods of the same taper, where step-downs were originally used, and see what the difference is. Say, one with a step-down, one with a SuperZ and the original step smoothed out, one with a SuperZ and cane swell ahead of the ferrule, and a SuperZ with a cane swell behind the ferrule. Maybe more questions than answers, but hey, that's OK! :-) Certainly some things to ponder. Nothing wrong with that! (Todd Enders) I think the step downs add to a snappier feel in the tip. The action seems crisper. Of course, this is due to the taper dropping over the ferrule. Also, in the Don Phillips book, he claims the step down is best for bamboo (I think due to decreased stiffness). And yes they do look better, in my opinion. (Bob Maulucci) Seems like the only way you could test this is by making the same taper, length, weight, etc. only differing the ferrule type -- is this what your statement is based on? Having never seen any discussion of the theory of step down ferrules and how the cane is prepared for them, etc. this discussion has been about as meaningless to me as it apparently has been to Todd. (Larry Puckett) I'm sure your statement to Bob M wasn't intended to sound harsh, but it kinda came out that way. I have done just what you suggest, several different tapers made with both step-downs and SuperZ style ferrules. Most classic tapers are "better" IMHO, with step-downs, though some were obviously designed with with Super Z in mind (Garrison, for example). A little experimentation might lead you to the same conclusion. (Harry Boyd)

It seems like part of the list members responding to the current ferrule discussion understand step down ferrules to be when a ferrule's male piece has a drop in size between the body and the slide portion that fits female. The exterior size of the female and the upper portion of the male are the same. When this type is joined together, they look nice because these tubes are the same size. The end of the bamboo on the tip must be turned to two different diameters to fit the male - the extreme end to fit inside the slide portion and above that to fit the upper portion of the body. The inside diameter of this ferrule where it transitions to the cane would be the same for the male and the female. No extreme drop (or increase) in the rod diameter at the ferrule station is needed or even desirable. The station should or could be the same size at the tip and butt, just like with a Super Z style. Now, I was under the impression that the maker's that had an extreme drop (or increase) in the rod section at the ferrule station were using a ferrule where the male slide was straight walled and of a single diameter which matched the inside diameter of the female. Picture a tube sliding into a slightly larger tube. The result would be an increase in the size of the bamboo between the tip and the butt at the ferrule (which would vary depending on the wall thickness of the tubing used). The discontinuity in the bamboo on either side of the station gave the rod a different action. I've seen this described in print - I think it would make the tip lighter and faster and the butt stronger. To me, this is what's meant by a step down ferrule. (Bill Benham) Both your descriptions can be seen as step downs. My interpretation of a true step down would be your first paragraph (described quite well I might add). The reason is that there is a true step down in the male ferrule so that the female can accept the male slide portion. Therefore the measurement at the ferrule station for the tip and the butt are the same before you adjust the male slide portion. Your description in you second paragraph describes a ferrule that I would call a "piston" style ferrule for lack of a better term. In this type of a ferrule the entire female ferrule is bigger in all respects. The ID of where the bamboo is installed on the female is bigger than it's counterpart on the male. The outside diameter of the female is bigger than the outside diameter of the male over the entire length of the female ferrule. This, as you say, would require you to have a different measurement at the ferrule station for the butt and the tip (butt station would be larger). I would not necessarily call this type of ferrule a step down, I would call the taper a step down taper. Now, a great compromise to these ferrules was the super Z; where the inside diameters where the bamboo is installed are the same on the male and female, but the female "expands" to accept the male. (Robert Cristant)

I'm just about ready to glue rod number 3 which is a Driggs River. I took the taper measurements from the Hexrod version that Wayne C. posted from the Young Beveler setup. My question is did the original use step-down ferrules? Should I? I believe that the ferrule is a 13/64. (Aaron Gaffney) I am becoming more and more convinced that where you see a need for a step-down ferrule, and if you can get one, use it! I have built a couple of Gillums and a heap of Payne 101's, some with the step-downs as originally fitted by the makers, and some using an averaging technique at the ferrule station. In my opinion the difference is chalk and cheese. The step-downs are a pain in the clacker to fit compared with, say, Uniferrules, but they really seem to bring these tapers to life. And, of course, that may purely be my imagination. (Peter McKean) I posed the same question regarding the Para-15 several weeks ago and never got an answer. I checked the Driggs taper in Ray Gould's book and it does not look like the taper calls for a step-down. There just isn't enough of a drop between stations. Some of the Young rods clearly used step downs, but other tapers did not. I have also seen recent Paul Young Rod Co. rods made with step down nickel silver ferrules and not the aluminum ones described on the originals. No one can tell me if the originals were step downs or not. A simple rule. If the original taper called for a step down, use a step-down. It makes a huge difference. Step downs are not that hard to fit. Measure the length inside the male with a drill bit. mark that length on your blank measuring from the station. Move back toward the station the length of the ferrule tabs and make another mark. From that second mark to the end of the blank is where you will take off cane. Start taking off cane from mark to end until the large diameter portion of the male begins to slide on. That is your large diameter, and it is the correct length. Stop. The trouble is that you can't easily measure or see the small diameter, but you do not need to. Measure the length of the smaller diameter section of the male from the outside. For a 13/64 ferrule, that is about .770. Make a mark at 0.500 inches and start turning the smaller diameter, but only back to your .500 mark. go slow- you want to slowly approach the diameter where the male just slides on. It won't go on all the way, but once it starts to slide on you have the correct small diameter. Just keep cutting back away from the station at the same diameter until the entire length of the ferrule fits onto the blank. You know when to stop because the ferrule will finally slide on all the way to your original mark (the length of the male measured from the inside, tabs included). Pop it off, and feather the edges with a file. Works every time. (Jeff Schaeffer) There's a little gadget called a "small hole gauge" that solves the measurement problem. Kitts Industrial had them on sale last year, advertised in "Home Shop Machinist" (catalog only, not in the store???) for under $10. I think they're regularly about $20 for a set of 4, from 0.125"-0.500". You slip the appropriate size into the ferrule and tighten the knob, then measure the outside of the gauge with your dial caliper. (Neil Savage) One of the main problems with the computer based taper number munchers is that they tend to smoothen out the drop across the ferrule stations on rods that were originally designed with step down ferrules. The software looks at the rod as a one piece rod with ferrules added. Since we do the work on 5" centers, the software will take a noticeable drop across the ferrule station and smoothen it into a nice, even dimensional change between the 5" centers that the ferrule happens to fall in. That's why you won't see the dimensions looking like they call for a step down Vs a Super Z style ferrule. Look at the dimensions on either side of the dimensions the ferrule falls into. That will sometimes give you a bit of a clue as to what the dimension at the ferrule station should be. Also take into account what kind of step down was used on the original rod, since the original maker's step down ferrules were all kind of different. (Mark Wendt) Here is a link to make your own graph paper. Or, you can just type in "graph paper" and there will be a bunch of listings for making your own graph paper. Use Wayne's old Hexrod program and use dimensions close to both sides of the ferrule. It will show the step-down stress values. I was trying to design a "Shop Rod", using an old step-down ferrule. One that I could leave strung up and when I had an urge for a casting exercise or to walk across the street to a small warm water lake, I would grab it and go! The ferrule was pretty big 14-15/64th, so I decided to try and make my own ferrule (for practice) and scratched the idea. (David Dziadosz) The way I think about step-downs is that the butt of the rod has to 'propel' the weight of the ferrule, whereas the tip does not. Therefore a thicker section on the butt compensates for the ferrule weight. Imagine exaggerating the ferrule. i.e. trying to cast an ordinary rod with an extremely heavy ferrule (e.g. a 3 ounce sinker as a ferrule). Now imagine leaving the tip but beefing up the butt of the rod to compensate for the ferrule so that it doesn't 'yank' the rod in the middle. It would cast a whole lot better than before. .....thus the step down. This is probably a lot of hocus-pocus to the scientists amongst us. (Stephen Dugmore) So, by using step-down ferrules, is it necessary to have a guide directly below the female ferrule on the butt section? Can the guides be spaced further away from the ferrule? (David Dziadosz) The Hexy apps will only munch the taper if the user allows it to. If the person that recorded a given taper notes that the rod used a step-down, and if dimensions at the ferrules are given, the dimensions can be put into most of the Hexy apps. It will still average in between the figures, but it will be a pretty close approximation. (Larry Blan) Your advice to look at the stations next to the ones near the ferrule is sound, but in the case of Paul Young rods there appear to be some tapers that require step downs, and others that do not. The taper for the Driggs is from the lovely reed, which has direct measurements. And I agree absolutely that it required a step down, use them. (Jeff Schaeffer) This topic is one that has always intrigued me, the question being why use a stepped down ferrule. It seems as though perhaps the step down ferrule was invented first and then tapers designed to fit it rather than the other way round. After all straight through ferrules such as the Super Swiss will each accommodate a range of about 0.015" or so in the bore depending on the ferrule size so there's no need to upset a smooth taper design. I believe the taper design should come first and the ferrules made to fit it. (Ray Gould) Looks like "Chicken Egg Chicken Egg Chicken Egg" doesn't it? Seems to me that the designer said "OK, here's the taper; now lets find a ferrule to fit it!" (Peter McKean) As a matter of fact it is my understanding that the Super Z ferrule was designed for use on the new Fiberglass rods. Due to their construction methods significant amounts of material could not be removed due to the fact that well it was a hollow section. Step down ferrules are my choice as well. The only time that Super Z's seem right to me is on tapers that have a strong mid such as the Paul Young parabolic tapers and the ferrule design doesn't influence the rod as much. (Bill Taylor) Garrison's way of thinking was to have a guide placed directly below the female ferrule on the butt section. His claim was it was a higher stress area. With step-down ferrules, should the guide be place directly above the male ferrule on the tip section? Seems that area would be a higher stress area. (David Dziadosz) I think Paul Young must have been a fascinating fellow, one I would have enjoyed getting to know. Though I have no way to verify my feelings other than observation of his rods, I think Mr. Young must have been amazingly talented, and at the same time, quite utilitarian. Most of the PHY rods I have seen seem to use whatever ferrules he could get at the time for a good price. For instance, Sante Guilliani's Perfectionist, which originally belonged to Martha Young, uses cheap aluminum step-down ferrules I fell in love with that rod in spite of its meager cosmetic appeal. I can't speak for even the majority of PHY rods, but I know lots of the parabolic rods did use step down ferrules. And why not? Step down ferrules seem quite simple to make compared to Super Z style. The female is basically a straight tube, and the male is two straight tubes, one inside the other. (Harry Boyd)

All this talk and step down ferrules has me wondering about the Payne 197, which is my next (2nd) rod. I've got it roughed and in string. Does anyone have measurements for this that have the step down at the ferrules? I forget where I found it, but here is the taper I'm using: Payne 197 7'6" 3 piece 5 wt 0 .062 I think you'll see the drop between 35" and 30 ", and 65" and 60" on the taper you posted. You would likely be fine with straight male ferrules (Super Z style) but closely following the original would call for stepped ferrules. Maybe it's time we moved back to discussing why stepped ferrules are important. Has anyone done any testing rather than relying, as I have, on how the finished rods feel? I know I've made quite a few 7' 6" 5 weights to the same taper with both straight and stepped ferrules. Comparing the two when casting is interesting, but not very scientific. (Harry Boyd) So Harry, given your nonscientific experiences, what do you feel is the difference between the two on identical rods, or can't you really tell a difference? I'm curious, not having had the experience of comparing two otherwise identical rods side by side. (Chris Obuchowski) There is a definite, and quite distinct, difference between the two rods. The biggest difference is in feel. And we all know how difficult it is to describe how something feels. I would say that the rod with the step down ferrules feels, first of all, smoother. It seems to have less distinction between the tip and butt. I haven't measured, but the overall curve of the rod seems a little less choppy -- although the rod with the Super Z style ferrules isn't at all choppy -- the stepped down rod just feels smoother. Second, I would say that the rod with the step down ferrules feels like it loads better in close. That might be because of the extra weight in those ferrules, huh? Third, I'd probably have to say that the rod with the Super Z ferrules is probably a little faster. It probably throws a tighter loop more readily. Of course, we're talking a Payne 101 taper here, so both of the rods throw loops plenty tight. Someone (Bob?) described a Payne 101 on here recently saying they thought it was a 6-7 weight rod. Every one I have cast loads best with a 5 weight line -- as do both of these. And every one I have cast, no matter what ferrules were used seems pretty fast in action. By fast, I mean most of the bending in casting occurs in the upper part of the rod. I've now made about 30 rods to the slightly modified Payne 101 taper I use. Probably 20 with Super Z style ferrules, and 10 with step-downs. I prefer the step downs, but your opinions might be different. (Harry Boyd) Do you have access to a gram scale, or a reloading scale? I'm curious if there is a significant difference in weight between a step down ferrule and the Super Z style for the same size (and what the difference is between a standard and a truncated Super Z). There is lots of talk of physics bandied about on the list, but sometimes I wonder if any of it actually approaches the realm of reality. (Chris Obuchowski) Chris and I have briefly discussed ferrule weights. Yesterday I spent a few minutes weighing some ferrules. I used a reloading balance scale capable of measuring in tenths of a grain. First I measured size 13/64 Classic Sporting Enterprise Super Swiss and Super Swiss ferrules. Both were standard length rather than truncated. Weights are one female and two males, combined. Super Swiss 143 grains Super Step Down 143 grains Just for fun, I weighed a set of Arcane Component works size 13/64 Titanium ferrules. At 68 grains, they are less than half the weight of nickel silver ferrules. I then measured CSE size 11/64 ferrules Super Swiss 107 grains Super Step-down 104.4 grains Conclusions: The extra length of CSE step down ferrules (I didn't measure length) makes them weigh quite close to the CSE Swiss ferrules, even though the design of step down ferrules would seem to make them lighter. (Harry Boyd) I think your comment about needing more discussion on step-downs is right on the money. There are a lot of tapers floating around without much info on whether a step-down, truncated, or Swiss-Z ferrules is used and whether the taper was adjusted to compensate one way or the other. In that context it becomes very important to know which rods they were used on and the potential effects/tradeoffs of using one type of ferrule Vs. the other. (Larry Puckett) I would be interested in this also as my "testing" has been in the same manner, by feel. FWIW, I prefer step downs on all but paras as it seems the rods "feel" quicker to me. BUT! I have no other testing beyond the way a rod casts (which is really what is most important to me). To open potentially another topic, the "feel"( I think a little snappier) and look is also why I prefer flamed versus blond rods. I have nothing other than the way they feel and look to me and cast to explain this either. Good discussion, Harry. (Dewey Hildebrand) Thanks for the reply and for getting me on the right track, in regard to the Payne Tapers. I didn't realize you were talking about the 101, so I was really out in left field. No, I didn't realize that all the original Payne tapers used step ferrules. Why did he do that ? It certainly wasn't because they required them, some of his rods, like the 100 and 198 don't need them, so what was the reason, do you know. Also when we refer to a step ferrule is it always a step down from butt end to tip end. In other words, is the tip end of the ferrule always the smaller diameter? As you can see I am not very familiar with this type of ferrules, I have seen drawings of them but not paid much attention to their detail. (Bob Norwood) To add to what Harry has already said, and what I have been able to learn about the history of ferrule development, the Super Z's came about because rodmakers needed a way to joint up glass rods, and since you can't turn down fiberglass, the ID of both the male and female had to be the same (as Harry stated earlier). The SD style is quite good from a practical standpoint, and since you could turn down the cane to fit was ideal. They are lighter than their counterpart Super Z's (less metal of smaller diameter involved; an SD using tubing @ 14/64 uses a length of 14 for the female, a short length of 14 for the male, and a short length of 12/64 for the male slide. The Super Z uses two longish equal lengths of 14, and a piece of 16/64 twice as long for the barrel of the female). It seems like the rods that have a one to two 64's drop across the ferrule are from manufacturer's that used DRAWN/swaged single piece males, where you could only force expand the ID of the male .016 or so (1/64), hence the drop from say 14/64 ID in the female to 13/64 ID in the big end of the male. And to quote Hoagy Carmichael who wrote the book on Garrison (he said this to me in salmon camp on the Cascapedia, and maybe I shouldn't repeat it but here goes) "Jim Payne made the finest bamboo fly rods, in both performance and finish, bar none". (Chris Obuchowski) I have a piece of writing somewhere that when at a meeting someone showed Jim Payne a Super Swiss or Z ferrule, he said: "Why didn't I think of that." (Sean McSharry) Bully for Jim Payne and Hoagy Carmichael too. But there's not much evidence in the tapers. In terms of coherence in taper design, by which I mean that I can understand where they are coming from, whether I agree or not, then the makers who impress me are Dickerson, Garrison, Leonard and sometimes, Young. I forgot Richard Walker, how could I? The rest seem to be eager to prove that if you set an infinite number of monkeys typing at random then, sooner or probably (much) later, one will produce a perfect version of The Bible. Which inflammatory outburst was not at all why I started this. What I really wanted to annoy you all about was this business of step down ferrules. I know perfectly well how they came about, they were cheap and easy to make. What I cannot understand, for the life of me, is why anyone would want to introduce a step taper half way up a rod design. It produces all sorts of undesirable stress raisers and does nothing whatever for the action. Since rodmakers, and they were American rodmakers, got it into their heads well over a century ago that compound tapers were not only possible but desirable, the need for a sudden step became unnecessary, and the better ones just built up one or other or both sections to accommodate the only ferrules they could get. We have to thank the fiberglass revolution (which was, in fact, just an evolution) for the fact that we no longer have to indulge in this time consuming nonsense. Its not that you cannot make a perfectly good rod with a step at the ferrule, indeed, there are several of them around here, its just that you can make a better one without it. If you try. I cannot comment on finish. If Payne made rods better to look at than Edwin Barders that’s just fine, but I bet he didn’t. (Robin Haywood) There are good Leonards, but IMHO those would be a rather small minority of pre-fire Leonards. Most Leonards are about as generic as an Orvis, and quite a lot of them have actions like over-boiled spaghetti. I can't speak about later period Leonards, which simply struck me as uninteresting and unrelated to the real Leonard tradition. They probably do have significance in the eyes of those who follow Tom Maxwell's career in more detail than I have myself. Garrison made very intriguing rods with a theory (and a story) behind them. They had a unique action and an aesthetic of their own. They cast ok, but I've owned some, and I don't think they merit the prices they command on any basis beyond scarcity. Dickerson made a terrific 1930s-style fast taper rod, with respect to taper. His workmanship was not all it might be, however. Dickersons will commonly be found with watermarked cane, or worse flawed cane. His ferrule were poorly fitted. His varnish was unrefined. His reel seats were made for Pflueger Medalists, and could be unusable with decent reels. Dickerson extension butts don't necessarily fit right. Fast taper rods are good. Dickersons have a regional crafty flavor to them, and are scarce. But I doubt they'd bring big prices if they weren't so scarce. I haven't owned enough rods by Paul Young to comment on them. But there can be no doubt that James Payne, in many respects, made the finest rods of any maker. In the first place, (tho' I've never heard of Edwin Barder) I do not believe anyone ever equaled Payne's quiet good taste and absolutely first class workmanship. Payne rods are perfectly finished to the point of luxury, but are in no way vulgar, ostentatious, or unnecessarily stylized. Payne had no affectation. His tapers tend to be dead solid perfect middle-of-the-road tapers that do the job. A Payne rod is a pleasure to use. The level of quality is just different from other rods. Payne rods seem to be all excellent. Guys who used to frequent the Payne shop tell stories of Jim Payne personally performing certain tasks on every single rod. They also say that he often broke rods over his knee that did not for some reason meet his personal standard. It may very well be true. I believe the story that he sat and ran his fingers over single ferrule, and personally finished each one with a fine file. I believe it because Payne ferrules always fit perfectly. Unlike other makers', they don't start life too tight, and wear in. They don't need the angler reducing the male ferrule with steel wool. And Payne rods can be left set up on the porch of salmon lodge for a two week trip, and come right apart. It always takes two to four men to get other people's rods apart after such an interval. The only weakness I know of about Payne rods is the varnish. It is more beautiful than any other maker's varnish, and does not wear terribly well. No one --to my knowledge-- has ever succeeded in matching it, though I know a lot of people who have tried, and a fair number who claim to have succeeded. It is very sad that Payne rods will all age out their original beautiful condition as their finishes oxidize, and no one can ever bring them back. I keep mine carefully waxed. Some people I know own, and use, a lot of different rods. It's always true that one uses the Payne more than other similar rods, because it's easier to cast, and one has more confidence in it. If I had to choose one maker to make every rod I owned, and could pick any of the greats, I know my choice would be Jim Payne. (David Zincavage) Very nice analysis on makers and their rods. Very informative and interesting. Thanks for sharing! (Will Price) I was under the impression that you disdained bamboo for the sheer delight of greenheart. Do I have a disapprehension? (Ralph Moon) Not really. I just responded to a "do you use cane?" question, noting that I even commonly use greenheart too. (I don't use inorganic fly rods at all.) Greenheart rods are characteristically significantly heavier than split cane. Nonetheless, their greater power is desirable for spey casting and for very long casts with large flies. Beyond mere practicality, greenheart has a very different kind of action from cane with a distinct charm of its own, and an angling world in which greenheart was never used would be poorer for its loss. (David Zincavage) So what was it about the Payne varnish? Did they make their own? I would like to hear something about what made it look different from other varnishes. (Jeff Schaeffer) Nobody really knows. Some claim that Jim Payne thinned and heated his varnish. He is widely believed to have applied it with a brush by hand. He is said to done the varnishing of every rod personally behind closed doors, so no one would know exactly what he did. There is a report (which may be true) that you could see a lot of varnish on the walls of the finishing workroom, suggesting that after brushing on the varnish, Jim Payne whirled the rod section around, flicking off the excess. That story comes from a serious source. The problem is that that source claims he can reproduce Payne's varnish, and from what I've seen, he can't. It's certainly the case that if anybody ever really did figure out how to duplicate Jim Payne's varnish, he could get an awful lot of refinish work, and he'd have a serious claim to the respect of those who care about fly rods. (David Zincavage) I sat in the varnish room at Payne several times and watched Jim varnish several rod sections. I know the room in detail having slept there on several occasions. I have the shelves from the room in my garage. There is hardly any varnish on the shelves. There was more varnish on the floor than the walls. Jim hand varnished using a brush. The varnish was thinned and in a small container that was heated. After varnishing the sections, he propped them up against the wall setting on the shelve. (Hal Bacon) Your comment about the Dickerson rod reel seats being made for the Pflueger reel foot is especially interesting. I have found recently that some of the Edwards rods were made exactly that same way and it is very limiting to the flyfisher. (Ray Gould) I was discussing the integrity and consistency of their design philosophy. With many there is little evidence they ever had one. They operated as immensely skilled mechanics, nothing wrong with that, but I was talking about engineers. Nobody but a fool would ask an engineer to actually build a bridge, or a mechanic to design one. Perhaps I can make that plainer if I say that Dickerson and Garrison were engineers, Payne was a mechanic. (Robin Haywood)

I've been looking at the Dickerson 7613 1970 version as my next rod. The taper in David Ray's Taper Library lists a size 13/64 ferrule at station 45 which is 0.198. Station 50 is 0.213. That's a 15 thousandths drop between stations. Is that manageable with a 13/64 ferrule or would a step down ferrule be required? Input appreciated. (Wayne Kifer) I would go with a 14/64 step down because the .015 drop is almost exactly 1/64 of an inch. And I have concluded that if the original taper used a step down, then make it that way. The 0.213 station is 13.632/64th's. I would consider rounding up to a 14/64. You would have to take off quite a bit of cane and it just looks weird, at least to me. And the station will be stronger. Dickerson made his own ferrules, and I think that on most of his tapers you will find that with modern ferrules they really require one size larger than designated in the taper name. Someone correct me publicly if this is wrong. (Jeff Schaeffer) As with other classic rods, there seem to be multiple tapers of the same rod floating around. I made the one posted by Philip Rundhaugen in 2004, which he says is from Howell's book. He averaged the ferrule measurements to get 13/64, and that works fine. It LIKES a WF 6 wt. I think I still have the taper on my hard drive if anyone is interested. (Neil Savage) I don't know about anyone else, but I would. I'd rather not pay over $50 for a set of ferrules if I can use a set of Rush River Rods that I already have. (Wayne Kifer) That's one of the reasons I machine my own ferrules. (Mark Wendt)

I have a question about what to do and how to do it regarding whether or not to use a stepdown ferrule which I've never used before - someone mentioned they had two rods of the same taper one with a step down and other not and the step gave the rod more backbone. My question is as follows - I have a Dickerson 8615 taper I'll be putting ferrules to soon - the taper numbers at the ferrule stations are as follows : butt end of tip tip end of butt 235 257 = 22 thou. jump. the 15/64ths ferrule I have measures 230 inside diameter female ferrule same male ferrule. I'm more concerned about taking the 257 down to the 230 to fit the ferrule than anything else at this point. How would you guys fit this rod and why?? (John Silveira) SORRY _ upon re-mic’ing the inside diameter of my 15/64th ferrule it's actually 234 not 230. (John Silveira) I would use a 16/15 step down. You might be tempted to think that you are only taking off .011/.012 per side if you fit the #15, but if you consider the corners, you are taking off a lot more. You might get away with it for a long time if you fit very carefully, but I would always be suspicious of the strength of such a joint. I don't usually make tapers with step downs, so someone else will have to advise the ferrule source, There are different kinds of step downs. I would look for one where the ID of the tubing where the cane enters is actually 16/15 butt to tip. (Tom Smithwick) I don't know who coined the term "stepdown," but to me it's a misnomer. The only part of a step down ferrule that steps down is inside the male sleeve, the main diameter of both the male and female are the same. A true step down ferrule would be like Tony Larsen's that are 1/64ths different where the bamboo goes in, or a fiberglass rod metal ferrule. I think rods with "step down" ferrules are stiffer because the ferrules are longer. What I do with tapers like yours is size the ferrule to the butt diameter turned full round, the bamboo on the end of the tip will just have the corners knocked off, or it will be full round inside the slide portion of a step down ferrule. (John Channer) I hope it was not me said that, because I didn't mean to. I did say that I thought that the old tapers which seemed originally to call for a step-down ferrule seemed to be better actioned rods when I use one. A step-down with a difference of 2/54ths will probably accommodate your drop across the ferrule, or you can do what a lot of makers do and build up the tip end with some strips of bamboo glued on to the section, and then turned down to fit the ferrule as usual. I believe that the one thing you ought not to do is to depend on glue to fill the gap. (Peter McKean) That is a big step for a Dickerson taper. The 8015 Guide has an .018 step and the Guide Special .014 and understood that the 8015 was less than either of them. Curious to the source of the 8015 taper? (Tim Pembroke) The way that rod mic's out, you need a 16/64 step down ferrule. Those dimensions fit almost perfectly a 16/64 female and 15/64 male. (Mark Wendt)

I have a Montague Rapidan, 9' 3 piece, 2 tip that I want to restore, not that I don't have enough on my plate already... I've carefully removed the guides and ferrules (both male and female on the mid section had ticks) to "get down to the blank" to strip the varnish and re-wrap with my own guide set. I'm going to add in a couple more snakes. The rod is not going to be restored to original configuration as I'm actually going to fish it. I couldn't see fishing the rod with only four snake guides (grin) and the ferrules that I took off were not in good shape. I want to replace them, they are the step down type Do you guys have a suggestion for what type and where to get a replacement ferrule set? It's a three piece, two tip rod, I'll need a complete set of ferrules for it. Below is what I found, if you have a better choice, please, let me know, if not, which choice would you make? Again, sorry to be a pest. There are several sources:

Watch out for ferrules from "Junk rods." Montague was known for making junk ferrules for its low end rods. (Terry Kirkpatrick)

I'm working on my first rod, a Dickerson 8014 from the Howell's book (1949 version) and the difference between the butt and tip seems very large (.014). I have an original Dickerson 861711 that uses stepdown ferrules, so no doubt the 8014 rod was designed for stepdowns as well. Come to think about it, all the rods in my small collection (Grangers, Heddons, FE Thomas, Payne) sport stepdown ferrules. Since some of these rods are 70 years old and still fish well, strength doesn't seem to be a factor. So, should I use stepdowns on this 8014? Do Super Swiss offer a better action? Is it a lot more difficult to install stepdown ferrules? Where can I go to find more information on installing Stepdowns, since all the books I have deal only with Super Swiss? (Reed Guice) But I don't have an experienced answer to your question. From what I have read and been told you shouldn't mix and match tapers and ferrules when the taper was designed for step downs. Someone with more experience should be able to explain why. (Scott Bearden) Dickerson designed all his tapers utilizing step downs as far as I know. I've also read and been told here on the list and elsewhere that once you hit a difference of .012 step downs should be used. A few have even said that .008 is the cut off. I've stuck with the .012 and it's always worked for me. The 8014GS is the only bamboo rod larger than 7 1/2' that I fish with as I prefer to fish the shortest rod I can get away with whether it's grass, glass or plastic. Long graceful casts may look great on the lawn or in a casting competition but are pretty much impractical under most fishing conditions. Any time your fly is more than 40' from your rod tip the chances of a successful hookup are greatly limited. That being said, every bamboo lover deserves at least one cannon. I can't think of a better one than the 8014GS. (Will Price) If the openings (where you fit them to the cane) on Swiss/Super Z are the same as step downs, why does it make a difference? (Rich Margiotta) What you say is correct for a stepped ferrule. A stepped down ferule has a smaller dimension of cane on the male side, so there is actually a step in the taper through the ferrule. (Steve Weiss) Usually, they're not. You'll generally see roughly about a 1/64" difference in the stations. You have to look carefully at the station dimensions when using Hexrod, RodDNA, or any other software that has dimensions on 4" centers, as they will tend to average the dimensions across the 5" span to smoothen the curve. There's been more than a few times where I've had to interpolate and figure out the correct dimension at the tip ferrule station based on what the butt dimension is, and what the tip dimension should be, and then work that forward to the next tip station. (Mark Wendt) I've experimented with Hexrod by entering rod dimensions, 1/4" apart at the ferrule station and it would show the stepdown in the dimension graph and the stress graph. But not in the detailed numbers. (David Dziadosz) Yep, when you're dealing with the smaller increments, you can get the correct values for the dimensions. I was talking about using the taper the way it was presented using 5" dimensions, with will smoothen out the step down. And there was a typo in my previous post. I said 4" centers when I really meant 5" centers. Doh! (Mark Wendt) It would seem that a useful modification to Hexrod & similar programs would be to allow for discontinuities between sections, at least in the planing form settings. The form settings at the end of a rod section should not depend on what the start of the next section measures. I'll see if I can change this in the online Hexrod. I don't know if this makes sense...I can't have any coffee until I get my blood work done in an hour. The online Hexrod takes the measurements you give and uses pairs of measurements to interpolate to 1-inch stations. Once it gets the 1-inch stations any finer detail you provided is lost. Again this may be something for improvement. (Frank Stetzer, Hexrod, Taper Archive, Rodmakers Archive) I, for one, think the discontinuity between sections makes a lot of sense, especially when we are talking about using Payne and Dickerson tapers. I'm not sure being able to input anything smaller than one inch stations makes a lot of sense, unless it's a very simple modification. Use my 2 cents toward your coffee. (Neil Savage) How would that affect the making of the stress curve though? Doesn't the stress curve computation sorta depend on a continuous length, with all the other variables like line weight, guide weight, varnish weight, ferrule weight and whatever else tossed in? If you break the rod down into two, three or more sections, how difficult would it be for the stress curve calculations to put it all back together? (Mark Wendt) Yes for the stress calculations you need to treat the rod as one continuous entity. But for planing form settings it makes more sense to treat it as separate sections. The planing form settings for a section shouldn't depend on what happens in the next section, like a jump in size for a stepdown ferrule. Another person emailed off list that the same issue happens with butt swells. As far as stress calculations go, the action ends at the swell, but you need those swell dimensions for the form setting, so if the program throws them away the builder has to add them back in again. Something for me to work on in my spare time. (Frank Stetzer, Hexrod, Taper Archive, Rodmakers Archive) I agree wholeheartedly!!!! It is a pain in the butt to have to interpolate dimensions for step downs with the way the rod databases are set up now. It'll become even more important as folks start making and using CNC machines to cut tapers too, having separate sectional dimensions. (Mark Wendt) When I was really using the Hexrod program from Wayne's first book, I found a web site where I could make my own graph paper. It makes it easy to interpolate dimensions. (David Dziadosz) You would have to go and make things easy, wouldn't ya? C'mon, yer takin' away my chances to complain... (Mark Wendt) I had to do something! You should've seen the stress graphs that I was drawing with the graph paper I was getting at WalMart, here in North Arkansas, err, Central Missouri! (David Dziadosz) I've made a change to the online Hexrod, so that the ends of the planing form settings for each section are extrapolations of that section only. This should give more reasonable settings for rods using step down ferrules, like Dickerson's, but not affect settings for rods with continuous slopes through the ferrule station, like Garrison's. If problems arise, let me know. The change was trickier than I first thought. I will make a similar change for the MHM settings when I have some time. I don't have weights of step down ferrules, so if you are serious about your stress values you'll have to weigh yours. I assume they are less that standard super Swiss but maybe they are close to 1 size smaller, or the truncated version??? (Frank Stetzer, Hexrod, Taper Archive, Rodmakers Archive) Schweet! I'll have to give it a peek later on. Any thoughts as to having an output in 1" increments for those of us that will be using something besides planing forms/MHM's? Savable to a text file preferably, so I can run a Perl script or two to generate G-Code? (Mark Wendt) Since I have never built a step rod could one of you give me the dimensions of one, especially at the step so I can see exactly what you are talking about. It seems that all the tapers I have been converted to a conventional ferrule. (Bob Norwood) Typically, you'll see a roughly 1/64" step-down in the section dimension at the points on the sections where the ferrules are mounted. I say typically, since there are exceptions to that rule because not every maker made their step-down ferrule the same way. Some had longer barrels, I think there were also stepdowns made where the drop was 2/64". So, it all sorta 'depends' on who designed the taper, and what step-down ferrule was actually used. (Mark Wendt) Tom Smithwick's taper for the Dickerson 8013 is an example. Setting the planing form from the measured dimensions would be result in a tip too fat and a butt too slender at the ferrule station (48 inches). (Frank Stetzer, Hexrod, Taper Archive, Rodmakers Archive) Thanks for the taper, but I'm not sure of what you mean by a tip too fat and a butt too slender? If you were making this as a stepped taper what would the measurements at the lower tip and upper butt be? It seems to me that the ferrule is at 48 inches and that leaves only 2 inches at the butt top most of which would be under the ferrule. same with the tip most of it would be under the ferrule also, at least to the 47 inch point, which leaves only 3 inches in question. (Bob Norwood) It's fairly easy to tell tapers that used step down ferrules originally, for one thing, almost all classics used step downs. To my knowledge, the only tapers designed for Swiss ferrules are Garrisons, Uslan pentas and later Young's. Swiss ferrules will work fine on most rods if the difference isn't too drastic. If you want to figure out which tapers really should use step down's, then look at the taper graph (not the stress curve), if you see some strange things going on at the ferrules area rather than a smooth flow of the taper line thru the ferrule, then extrapolate where each section would wind up if the curve of the taper were continued on the ferrule end of each section and just stopped rather than trying to connect the lines thru the ferrule. I hope some of that makes some sense. If Frank is able to get Hexrod to graph each section individually instead of in a single line then it will take care of all this. (John Channer) I have done just that and my reply to Mark was the result of these taper extensions. Also I looked at the tip taper 15" before the ferrule and remarked that it has a flex or area where the taper isn't as strong and that area will bend more so the slight reduction of the tip part the ferrule will not (in my opinion) cause any problem regardless of the type of ferrule used. The butt has a slight reduction also but again because of the length of the ferrule back toward the butt of app. 1 1/2 in. again I don't think anyone could tell the difference between the two types. I did a test at SRG about 4 years ago with rods of slightly different tapers using the same lines; no one could tell the difference. (Bob Norwood) I was thinking of it more as a design tool. In spite of my dislike of the things generally it is possible to come up with feasible designs which would require them. Although I'm not disagreeing that that need could be designed out, its just a trifle more elegant and pure to use them. So far the only proposition I have come across where a step down may be useful is the design of a real "Parabolic" which does what Ritz says he wanted it to do, unlike the ones Ritz "designed" which do almost the very opposite. (Robin Haywood) The butt would be fairly close, since a 13/64 stepdown ferrule uses a .203125" dimension for the inside diameter of the female (and the outside diameter of the male slide), and a .1875" diameter for the initial inside diameter of the male ferrule. If you interpolate out the dimension at 48" in that taper, you'll have .2046". That'll work great for a super Z, but that would require a heck of a lot of material taken off the tip section for it to fit into the male ferrule. (Mark Wendt) I can't quite agree with you on this one. First if you look at stations at 30" to 45' you will see that the taper increase between stations is less that a normal taper increase for a 5 wt line of .014. They are from 30" to 45" 10,10, 9 to 45' I would expect the top to keep on this same slope which would make it .007 increase for the tip from 45" to 50. For the step ferrule, the tip would be cut at 48" leaving a taper Dim of about .1945 which would be trimmed down to .1875 for the male tip. Since the tip taper already has a flex area from 30" to 45' this should present no problems. The butt if extended out to 45" would be something like .208 requiring it to be trimmed down to .203 for the female ferrule, making it slightly less than it would normally be if you kept the same butt slope. So that what you have for the step ferrule is a butt that is .203 at the 48.5" point. and a tip that is .188 at the 46.5" point. the net effect is that you have is a butt that has slightly less bamboo and a tip that has slightly less bamboo, but the ferrule should add to the stiffness and cancel any small differences in the taper. If you look at the Stress Curve you will see the stress increase from 30" to 45" showing a flex areas there, how ever the butt has a negative slope from 70" to 50" showing a decreasing Stress Curve at this point causing a step down in stress either way, it's just a little more pronounced with the step ferrule. So no matter how you do it Step or Super Z the net effect will be very close to the same either way and I think very few people could tell the difference. (Bob Norwood) I think we're sorta agreeing here. The interpolation I was talking about is what the maker has to do to figure out what the dimensions are supposed to be at the ferrule mounting point. Those dimensions I was talking about below are just a linear interpretation between the 45" and 50" stations. The dimensions presented on that web page aren't what Hexrod or RodDNA came up with, those are actual measured dimensions flat-to-flat that Tom took. Now, if Tom had given is dimensions on 1" centers, we could actually see what the taper did between 45" and 48" on the tip, and what the dimensions between 50" and 48" on the butt. But, we're not given that information, so we need to interpolate what the correct dimensions would actually be, and the linear interpretation is a good place to start. It generally doesn't change much of the dimensions with the butt section, but sometimes you have to get creative on the tip section. (Mark Wendt) I guess if I were contemplating the dimension for a step down, I'd measure the ferrule I intended to use. No?? (Vince Brannick) Build up the end of the butt section with slips of cane. (Robin Haywood) It's not the butt end that's the problem. It's the tip end. (Mark Wendt) Generally if using a step down ferrule as a joint between two sections of the same diameter the ferrule was chosen so that its internal diameter on the male ferrule was the same as the flat to flat dimension at the joint. This resulted, inevitably, in a female ferrule of greater diameter than the joint flat to flat dimension so building up was necessary. Some of the very best makers, like Hardy when they weren’t larking around with weirdness, built up both ferrule stations to avoid rounding the corners of the cane at all. (Robin Haywood) Right. But that's using a step-down ferrule based on the design taper of the rod, rather than designing a taper based on the dimensions of the step-down ferrule. In this case, Dickerson's, he designed the taper based on the characteristic dimensions of his step-down ferrules. He had no reason to shim the butt section to mount the female, since the flat to flat dimensions of his butt designs were created for that specific ferrule dimension. (Mark Wendt) I would like to see an original Dickerson, or at least a set of his ferrules. I don't know how he made his, but Payne and Leonard ferrules are basically a mirror image of Swiss style ferrules. They are made of 2 pieces of tubing and the sleeve is the male slide portion of the ferrule rather than the female part like SS are made and the only actual step down is inside the male slide part. I get the impression from looking at the tapers that Dickerson's ferrules must have had an actual difference of 1/64th between the larger diameter of the male and the inside diameter of the female, like using a SS male with the appropriate size Payne type female. (John Channer) He did make ferrules that had an actual 1/64" step down between the female bamboo diameter and the male bamboo diameter where it enters the slide. I'm confused a little though, since Payne and Leonard did the same thing, whereas the Swiss style ferrules have the same diameter bamboo opening for both the female ferrule and the male ferrule/slide, which in the case of the Swiss/Super Z is one and the same. (Mark Wendt) You'se guys are making my head spin. I've only got one question (well maybe two or three): 1. Other than an intellectual discussion, does it really make any difference? 2. Does the end result help catch more and bigger fish? Like Carlos Rossie used to say about his wine "I'd rather drink it than talk about it." (Tom Key) You'se guys are making my head spin. I've only got one question (well, maybe two or three): 1. Other than an intellectual discussion, does it really make any difference? It might. It might lead to talking about how tapers were designed with the step-down ferrules in mind, rather than using a Super Z style ferrule. Or, we could end up talking about the aesthetic value of the step-down versus the Super Z. Lots of reasons for the discussion. 2. Does the end result help catch more and bigger fish? Well, this is a rod "making" forum, not a rod "fishing" forum... ;-) Like Carlos Rossie used to say about his wine "I'd rather drink it than talk about it." Apples and oranges. This forum would be the equivalent of a vintner's forum, versus a wine drinker's forum. Completely different sets of topics would show up between the two, though there would probably be some overlap in the taste and mouth feel category. The vintners have different issues than the drinkers do to talk about. (Mark Wendt) No but it does affect the action of the rod. (Jim Lowe) Well when I said food for thought I thought I could maybe wake a few guys up since the list was kinda quiet, but really I wanted to feed you guys (food for thought) not fatten you up! Anyway I picked Dickerson out of the air it could have just as easily been Phillipson or Hardy or .......... Anyway good exchange. Think I'll go fit some ferrules, (Super Swiss). (Joe Arguello) Ah, it was good food Joe. Spring time is in the air (well, except for the folks down undah) and I think everybody's out fishing, where it's not all blown out from all the rain. Besides, you know me, I never have an opinion on anything, and I really hate to talk... (Mark Wendt)