Bamboo Tips - Tips Area |

|

< Home < Tips Area < Machines < Lathes < Wood Lathes

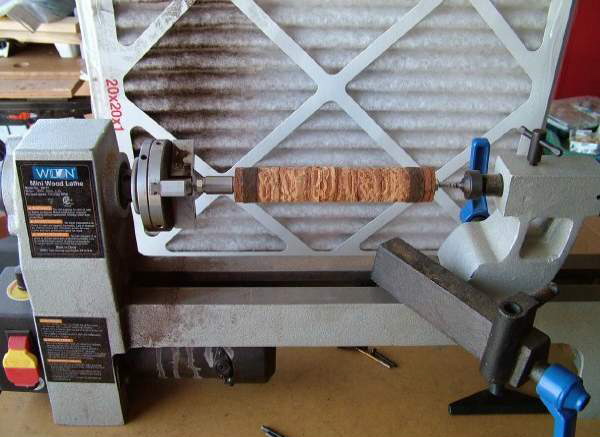

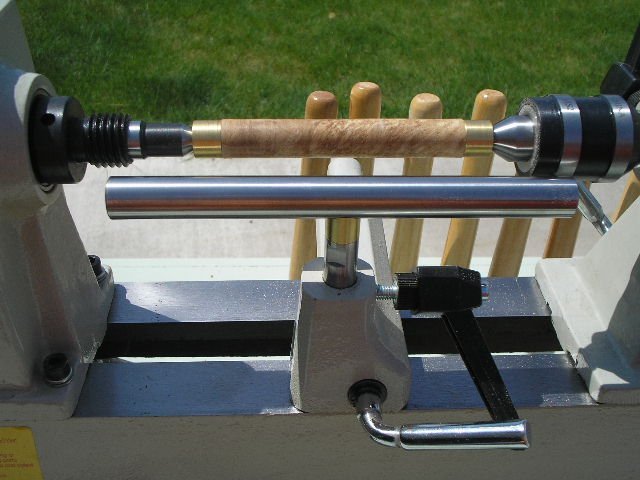

So, all this talk about Aluminum ferrules on small pack rods has me thinking about making my own some day. The only problem I think is that I have a Jet Mini Lathe and not a metal lathe. I head on over to www.mini-lathe.com where I'm sure it's going to explain the difference. Nope. So I browse the site looking for obvious differences that wouldn't allow me to produce my own ferrules and reel seats but I can't find any. With the exception of the thru-hole in the headstock being smaller, I can't find a difference. I seem to be able to get all the necessary chucks, etc.. The only real difference seems to be that the Jet runs at a slow speed of 500 RPMs. Is this were the problem comes in? A wood lathe won't run slow enough? (Jim Lowe) The main difference, as far as I know is the tool rest. A wood lathe is intended to be used with hand held tools, a metal lathe has a tool rest that holds the cutter rigidly, and is adjustable in and out and fore and aft in very small increments. You wouldn't be able to get the tolerances with a wood lathe, even if the wood turning tools would handle the metal. (Neil Savage) If that's all, then I'm covered. The jet mini has an adjustable tool rest. (Presumably for making pens.) (Jim Lowe) Well, give it a try. Aluminum stock shouldn't cost too much, so if it DOESN'T work, you aren't out much. (Neil Savage) In my opinion the electronic speed control on my Homier 7x12 is one of the major features that makes or breaks the suitability of this lathe for the various rod making steps where a lathe is needed. Having said that, I know there are many excellent lathes that are belt driven and do not have the variable speed control that the 7x(10,12,14) lathes have. I guess don't have the skill to use those lathes. Having spent a lot of time on a wood lathe in High School wood shop, and now owning the metal lathe, make sure the headstock has a big enough through hole, the chuck has to be able to hold something as small as a ferrule, the tailstock has to be able to hold a chuck and a metal working live center, and the tool post has to be a metal working tool post. You cannot hold metal cutters in your hands like you hold wood turning tools. Another area where a wood lathe may be lacking is in the setup for cutting threads. You will need that if you plan on making up or down locking reel seats. (Darryl Hayashida) Do you find that you have to go faster or slower with your lathe. The hole is 3/8 which I would presume would be large enough for ferrules, for now I can't see needing anything larger than a 17. I think I'm OK regarding the metal working live center as well. The cutting thread set up is something else but as long as I limit my work to ferrules and slide band, it looks like I might be OK. (Jim Lowe) After I get everything set up - whether it is making a ferrule or turning down a ferrule station, shaping a handle, etc. I start up the lathe slowly and let it spin at 50 - 100 rpm for a few seconds with a finger on the stop button to check if anything is out of balance, not tightened, hitting the head or tailstock, etc. If everything looks good at that speed then I speed it up until it's at operating speed, still ready to hit the off switch. If everything looks good, then I start the actual operation - cutting, sanding, whatever. This precaution has saved me many times - leaving the chuck key in for instance, and I haven't done the rod propeller yet (knock on wood). (Darryl Hayashida)

I'm looking for some guidance on a wood lathe. I have no desire to turn metal, as in ferrule and reel seat components. All I am looking for is something for turning wood reelseat inserts and ferrule stations. What is a good small lathe suitable for these projects and what should I expect to pay? Are there good low cost new units out there and what about the used market, such as eBay? I've seen some old Craftsman stuff there and a lot of low priced new stuff I suspect is just cheap junk. Don't know anything at all about the relative quality of older Craftsman, Delta, etc. equip. (Larry Puckett) I have been using a small Grizzly lathe for a year or so. I was a bit disappointed with it for a lot of reasons. Then I got a Jet mini lathe, and now I am pretty happy. Big difference in quality. One thing to make sure of, when you get a lathe, make sure that the spindle bore is open all the way through. My Grizzly lathe had a plastic case with electrical components in the way of the spindle bore. Anyway, the Jet is now $199 for the old model and $299 with electronic variable speed control (which would be nice). For the same price you could get a larger lathe from Harbor Freight. But, if you want a small one, I’d stick with the Jet and the Delta. Good solid lathes, not too expensive (relatively, of course), and with good motors. (Jason Swan) Don't get a wood lathe for rod work. I did, kept it for a year and sold it and bought a metal lathe. You can do everything on a metal lathe that you can do on a wood lathe plus much more. Also, the metal lathe is so much more precise in its construction. The head and tail stock on my wood lathe were way out of alignment. Ferrule cutting was difficult. Pay the extra $50 and get a metal lathe. (Mark Dyba) Besides, 80% of the replies I got re: Harbor Freight quality were negative. (Neil Savage) About a year ago I was thinking the same thing - wood lathe instead of a metal lathe. As it turned out the $300 Homier metal lathe was real close to the wood lathe prices. Unless you have other reasons for staying with a wood lathe I would get a 7x12 (or 7x14) metal lathe. The metal lathe will do all the operations you are talking about quite proficiently and if you ever in your wildest dreams consider making your own ferrule (it isn't that hard!), you will be set to do so. I also looked at it this way - at approx. $50 per ferrule the lathe paid for itself very quickly. Let me also reiterate that I feel the electronic variable speed control is something I would not do without, saving me from doing the "rod propeller" while turning ferrule stations many times. (Darryl Hayashida) I got a Ryobi (new) a while back for about $170. The spindle (headstock?? whatever, you know- the motor driven end!) was hollow but was a bit small for butt sections so I drilled it out a bit, didn't require too much drilling, still plenty of metal left so I don't think this weakened it to any degree. The plastic housing also had to be holed in the back to run the rod through but this was no problem. I ordered a 3 jaw chuck for hex shaped rods (about $45 at the time, if I recall correctly). Works great. Pretty small and relatively light, I just chuck it under the bench when I am not using it. It has a variable speed control which I really like. So far no problems after about 3 years of use. I only use it to make handles and spin down the ferrule stations. Occasionally use it to modify some stuff for around the house (don't ask about the time I took it apart and mounted a wood kayak paddle in it to spin down the paddle shaft for my daughter's hand size- it worked but it was definitely a Nunley experience, not recommended for safety reasons). Saw one recently for about the same cost so I don't think they have gone up much since I bought mine. I thought I would do a web search for you and, ta-da!, I can't find any! However, I did find one here. This is the exact same lathe that I have but is under a different name. I suspect Ryobi must have relabeled the lathe I have for sale under their brand name. Anyway, just one more option. (Jon McAnulty) I started with one of the Ryobi wood lathes, worked well but I found an old South Bend metal lathe and after using both for inserts and handles all I can say is spend the extra and get some sort of metal lathe. Those metal cutting tools work just fine on wood and I just rigged a cutting tool rest and can still free hand if I really want to. The Ryobi wood lathe is now used with a leather wheel for sharpening plane blades. (Gary Jones) I would second what Darryl says about the Harbor Freight lathe. I exchanged e-mails with him before I bought my Harbor Freight. I am very happy with mine and the company was a pleasure to work with. The thing does a great job of turning wooden reel seat fillers, metal components and a multiplicity of other rod making jobs. I think it is hard to beat. I am getting geared up to make some game calls with it as an aside. (Ron Revelle) Now I am confused! I thought Darryl was talking about the Homier lathe and you're talking about the Harbor Freight lathe. Did I miss some posting(s)? Tool quality generally varies with each importer even if the manufacturer is the same. (This is not meant to imply that Homier and Harbor Freight import from the same manufacturer as I simply don't know.) (George Bourke) They are the same lathe. There are minor differences in the electronics and bundled tool sets, but the important parts of the lathe are the same - same motor, same bed castings, same housing, same gears, etc. (Darryl Hayashida) For what you want to do I would seriously think about the Homier 7X12. I like the features on it more than the other 7X12's, also the price. It does have the speed control on the start up. This feature alone makes it above the others. It also it has an instant emergency stop switch. You may just want to make grips now, I assure you that if you do get a lathe there are always other things you will use it for. (Tony Spezio) About 5 years ago I purchase a "cheap" Harbor Freight wood lathe for doing cork handles on "plastic rods". It worked well for turning cork handles but it was just not satisfactory for doing ferrules and other work for bamboo - the best I could tune the lathe "wobble/out of round" was +- about 15 mils (0.015 inches) at 4 inches outside the chuck. This is not good enough for ferrules stations and other work in my opinion. I have a Grizzly metal lathe that holds +- 1 mil at 4 inches outside the chuck which is quite satisfactory in my opinion. So I would be careful of a "cheap" wood lathe (unless it is an upscale one) and think about one that you can do both wood and metal. (Frank Paul)

While running errands this morning I stopped by a newsstand and picked a copy of "Shop Notes" Volume 12, Issue 73. The feature article is a shop made wood lathe. This particular one has a solid head stock shaft, but, I bet things could be modified a little bit so that a hollow shaft could be used. Then the lathe would be good for reel seat fillers and ferrule stations. It will not work for anything metal. (Dick Fuhrman) What type of Lathe you guys using to turn bamboo for ferrules?? (Dave Henney) I use my Homier 7X12 metal lathe to drill the center hole. Slip it on a dowel that is held in the three jaw chuck and shape it with a file and sandpaper. I will be doing an article on this in a future issue of Power Fibers. (Tony Spezio) Are you talking about making a ferrule out of Bamboo or about turning a ferrule station? I read Dave question as being about turning a ferrule station. However, upon rereading the question, I see how it could be read as about making a Bamboo Ferrule. (Dick Fuhrman) Homier 7 x 12. (Mark Wendt) J. C. Bogeman modified Taig. (Neil Savage)

I know that I will catch it for this but here goes. Does anyone here own a Jet mini lathe and if so, how do you set it up to end bore wood rod handles? (Shawn Hawkins) Wow, that's ambitious for a Jet Mini. You will need to have a bed extension, of course. The length of a 6-7" wood grip, a similar length of drill, and a drill chuck would easily exceed the length of the bed. I haven't done this, but if I were to do it I’d think about getting one of those nice mini-lathe steady rests that PSI and Craft Supplies has. Or make one. Then, I think it could be done with an augur bit and patience. I'd also put it in a 4 jaw chuck so that you don't risk anything if you drill too far. I'd love to hear how it turns out. Send photos if you can. I've always really liked wood grips. (Jason Swan) You want a tool called a lamp auger. It is a handled tool designed to be fed through a hollow tailstock, and they are usually 3/8" OD. One other way is to chuck up your drill bit in the three jaw chuck, remove the tail stock, and shove the piece in on it's center. That's how I do all my tool handles. But without some practice and good luck you won't get it precisely centered each time. Read the section on turning tool handles in "Turning Wood" by Richard Raffin. He also has a video of the same title. (Brian Creek) Catch it? I think that it is a very reasonable question. There are two ways to center bore a handle or wood insert. Take the square blank, and turn it down to close to OD. Chuck it in your jaws, and hold the other end with a steady rest. Once you get the bore drilled (chuck a bit in the tailstock), mount it on a piece of threaded rod and turn down to final diameter. I don't like this approach because it is tough to keep the bit from wandering about. I use a drill press. Turn your blank using the spur driver until it is just round. Then mount it in a milling vise, and drill it halfway, then reverse. Then mount it on a threaded rod. It will be a bit off, but as you turn down to final diameter it will become center to the rod. I do the initial turning because I found that most of my blanks are not truly square, and if you are off it can cause problems later when cutting mortises and the like. Mounting a circular piece in the milling vise gives the bore hole more accuracy. This applies to any lathe - not just the Jet. As long as you have enough bed space you will be fine. If you don't then nothing will help. (Jeff Schaeffer) I use a drill press but with a different twist to cut down on setup time. To find the center, mark both ends of the blank from corner to corner. With a Forstner bit, drill a hole about 1/4" deep on one end. I made a plate to put on the DP table with a stud that will fit the hole & aligned with the bit. Turn the blank around and pass through the center of a mill vise and over the stud. Line up the blank with the bit and clamp the vise. No need for squares, etc. Drill as far as you can, flip the blank and align as above and drill the rest of the way. To turn the blank: Make a mandrel from a long hex-head bolt and cut the head off. Drill a center hole on the thread end. With a couple of washers on the cutoff end for spacers, mount the mandrel in the 3-jaw so that some of the threads are sticking out of the blank. Put the blank on the mandrel till it is against the washers and use a live center. You don't need a nut because the threads will keep the blank tight on the mandrel against the washers as you turn. When finished turning, use a cutoff tool to cut to length down to the mandrel. Remove the insert and do the next one. Another plus for this setup: After a while the washers will be the right diameter so that you can gauge when you are done turning. (Don Schneider) He has a tutorial and will be happy to share his secrets if you ask him. You want to drill out your blank first and then put it on a mandrill before you turn it. (he sells the mandrils) That way if you are slightly skewed when you do the turning everything will come out right (as they say on this list, don't ask me how I know that}. You can do 3/8" or 5/16". You can buy the bed extension for only fifty bucks or you can make one of wood. I do a pilot hole with a 1/4' bit first. (Dick Steinbach)

I've inherited a Grizzly wood lathe that I want to use to turn grips and ferrule stations. Unfortunately the chuck jaws do not close all the way enabling me to hold a section of a fly rod. I called Grizzly and they said they don't have a smaller chuck. Does anyone know where I can find a chuck that closes all the way. The thread is 1-12. (Gary Young) I was able to turn a grip on my wood lathe by center drilling a 1" dowel to accept a 1/4" mandrel and I put the cork on the 1/4", held the other end with a live center. I don't think I'd try to turn a ferrule station on a wood lathe even if I had a chuck that would close on the rod. I don't think you'd be able to get enough accuracy to get a good fit. Better to hand fit the ferrules, it's not that hard and it doesn't take all that long. Most of us seem to use small metal working lathes for such work, Taig, Sherline, Homier etc. Hope this helps. (Neil Savage) If you have a three jaw self centering chuck, it probably has reversible jaws. If it has, the jaws might be installed in the reversed position. This will keep the jaws from closing all the way. The jaws are installed this way so that it can grip a piece of hollow work internally. Wood lathes are used a lot in this manner. To reverse the jaws, remove one jaw at a time and flip them end for end. Then with the chuck key, turn it backwards till each jaw clicks, then turn to tighten. This should catch and start closing the jaws evenly. If not, do it again till all the jaws close evenly. Be sure the jaws stay in the same slot as the slot you removed them from. Each jaw should have a number on it from one to three. in some cases the chick body is also marked. (Tony Spezio)

Can anyone point me in the direction of a good mini wood lathe? I don't want to spend $800 on a Sherline for turning cork grips and reel seat inserts, but I would like something with a hole through spindle to be able to turn down ferrule stations if possible. I've read good reviews about the Wilton 99177, but I do not know anything about it other than a lot of pen makers use lathes like these and like them. Anyone use one like this or similar that could lend some advice? (Scott Bahn) I think it would be hard to turn a ferrule station accurately enough on a wood lathe (at least it is for me!) Check Penn State Industries, or www.cartertools.com for a less expensive metal lathe. (I really like my Taig) No financial interest. (Neil Savage) While I have been an advocate of finding used lathes in the want ads in newspapers and at flea markets, I have found a new source for lathes. That is Craig’s list. I regularly see used lathes, and other tools, there at good prices. (Rich Jezioro)

I almost purchased a wood lathe today for turning cork handles "on-the-rod". I was not sure, however, what an ideal diameter hole would be through the head stock. This was a "General" brand Maxi-Lathe (Model 25-100 M1) and has a .375" hole from the manufacturer. I am sorely tempted for this and other purposes, but want to do my homework first. Any advice? All I could locate in my own archives was a note from Don Schneider that he bored out his head stock and chuck to accept .780". (Greg Dawson) IMHO, .375" is too small if you want to make large rods. Mine is bored out to .580". It would be fine if you want to turn handles on a mandrel, obviously. (Neil Savage) A spindle Interior Diameter of 0.375" is too small for a lot of rod butts. Remember that the ID of 0.375 only allows a rod but of less than 0.325" to go through. If you stick to smaller lighter rods it would work for you. (Larry Swearingen) I don't know the configuration of your lathe, but I use a regular Morse tapered Jacobs chuck to hold the very end of the hexagonal cane butt and have the handle as close to the chuck as possible and the rest of the rod hanging off the right end of the lathe. I use an "L" shaped combo of boards to hold a ball bearing that can be bought at Lowes with about a 3/8" hole in it to hold the center of the rod section and another at the rod's end to hold that. So, going from left to right, you have the headstock, the Jacobs chuck, the butt, the cork, the center support, and the outboard support. The latter two are mounted in such a way that it matters not HOW long the bed of the lathe is (mine's 36" and it's never long enough). I wrap the cane section in masking tape oriented so it won't be peeled off by the rotation direction and use a fitted sleeve (cork or somesuch) if the bearing hole is very much larger than the rod's diameter at that point so nothing flops about. Keep the support nearest the cork NEAR the cork and you'll never know there wasn't a REAL tailstock used in the op. After all, using wallboard sanding mesh and sandpaper on cork doesn't exactly create a helluva lot of side force. (Art Port)

What is the difference between a wood lathe and metal lathe and what prevents you from turning metal on a wood lathe or vice-versa Sorry, its been 20 years since my last shop class. (Matt Baun) What is the difference between a wood lathe and metal lathe?

You CAN turn cork handles easily if you have a headstock mounted 3-jaw chuck, maybe easier than on a metal lathe with the higher rpm capability. Again with a 3 jaw chuck you CAN turn the bamboo ferrule stations using a file, just not with the easily attainable accuracy that you can with the metal lathe. (Larry Swearingen) Not exactly so ... my 7x12 metal lathe and my 10-x18 wood lathe have the same exact motor. They both have VSC to adjust the rpm. The wood lathe does have a 3 step pulley so I can flip the belt to another one for higher rpm's on the wood lathe but I have never done that. I've turned aluminum and copper and brass on my wood lathe. (Ron Hossack) Quite a bit of difference but I think you already got the info. The only thing really the same is, they turn. (Tony Spezio) I haven't seen this part in the answers posted though: You can turn wood on a metal lathe. In fact, a lot of pen makers prefer one for its improved accuracy. I turn reel seats on my metal lathe so I get the diameter I want. I'm not that good at making an exact diameter on a wood lathe, although I have both machines. My metal lathe won't handle long/large diameter stock though, it's a mini (Taig). (Neil Savage)

I went and got a Performax mini wood lathe at Menards, but am completely new to turning wood and need some advice. It has a 10" (at least) bed and variable speed with lowest at 750 rpm. It has a Morse #1 spindle and 3/ 4"x 16 headstock with a 3/8" thru hole. The tailstock also has the 3/8" hole and just the typical short 60 degree point. I hope to turn handles both off and on the blank and reelseat inserts. I wondered if I need to find a way to slow it down further, and I wonder what type of chuck would work best and what I need on the tailstock to hold a blank or wood/metal dowel for the grips. I probably bought something too cheap ($110) but I don't intent to make bowls or anything but above mentioned things. Any advice? (Dave Kemp) A 3 jaw chuck for the head stock works very well. A live center will work on the tail stock, especially if you use a drill bit and put a "countersink" in the end of the dowel. The 3 jaw will also hold the rod section for preping to mount ferrules. (John Dotson) I went and got a Performax mini-woodlathe at Menards, but am completely new to turning wood and need some advice. It has a 10" (at least) bed and variable speed with lowest at 750 rpm. It has a Morse #1 spindle and 3/ 4"x 16 headstock with a 3/8" thru hole. The tailstock also has the 3/8" hole and just the typical short 60 degree point. Some folks would fault the MT1 but if you were in the UK that seems to be the norm. This should be the same as the Wilton Mini lathe (silver and blue). It is a nice lathe as I have one I turn my grips and inserts on.

I can turn my VS down to where the the chuck barely moves so something isn't quite right there. I hope to turn handles both off and on the blank and reelseat inserts. I wondered if I need to find a way to slow it down further, and I wonder what type of chuck would work best and what I need on the tailstock to hold a blank or wood/metal dowel for the grips. Check the knob on the VS to make sure it is tight and not slipping. The lathe should have come with a dead center. I use it in the HS and a live center in the TS and hold the wood between them. If I'm using a mandrel I use either a 3 jaw chuck or a set of collet chucks.

For the TS get yourself a good Live Center, you won't regret it. Grizzly has some nice ones.

I probably bought something too cheap ($110) but I don't intend to make bowls or anything but above mentioned things. Any advice? I bought mine at Menard's when they were clearing them out for $69 ... nothing wrong with that lathe. I still use it a lot. (Ron Hossack) Are there threads on your headstock? Chucks screw onto the headstock. I have not seen one for a mortise taper. There are spindle adapters for chucks but you have to know the size and TPI of your headstock to get an adapter. Make sure your headstock and tail stock match up, centered on each other. If they don't, you will not be able to turn true circles. For the tail stock, use a live center. They can be found relatively inexpensively on Ebay. What are you going to use to cut the bamboo when turning? There are several options. If using lathe tools, make sure they are SHARP! They do make variable speed controllers for a wood lathe. They may cost as much as you paid for the lathe. then again a good chuck will too. I've been turning a lot of duck and goose calls and a few pepper mills and bowls. Though wood turning may be less expensive than working metal, it is quite easy to get far more into accessories than the lathe itself. (Rich Jezioro)

A coworker has an old Sears Craftsman wood lathe that belonged to her husband. It hasn't been used in years since he died so I don't know the condition or the age. She says come on over and get it and then pay me what you think its worth. So my question is would it be good for any rodmaking purposes and what kind of price range are we looking at here for a fair price for one in rusty, dirty, gnarly shape, one in average shape, and one in like new condition? She says she also has the tools with it so I guess she means an assortment of chisels etc. I'm hoping she will bring in the manual so I can get a feeling for the age but I bet it is 20-30 years old and hasn't been turned on in at least 10-20 years. I'm afraid that if I go pick it up that will more or less commit me to buying it so I don't want to get stuck with an overpriced lemon. (Larry Puckett) First, if the lathe has been stored in the dry (a basement or garage), it is probably fine, and just needs a bit of cleanup. A lathe is such a simple device that it is almost inconceivable that it can't be reconditioned. Second, you are going to have to look at it. Clear the trash away from it, knock off the loose dust and cobwebs, plug it in and see if it runs. Generally, electric tools weather neglect quite well. If it has a belt drive, that may need to be replaced. A burned out electric motor is also easy to replace. Also check the headstock and tailstock mounting device. Is it threaded, or Morse Taper or both? Is there a drive center, chuck or a faceplate for the headstock? Is there a live center on the tailstock? If the two shafts are solid with threads, check the thread to find out if you can buy accessories that will fit. The thread should be something like 1.5" x 8 tpi, 1"x 8 tpi, 3/4" x 16 tpi. All modern tailstocks are Morse taper, so if it has a threaded tailstock, it will be hard to find any tailstock accessories. Third, get the model number, and go on eBay to see what they are selling for. If anything looks damaged or missing, deduct the cost of repairs. Generally speaking, though, you shouldn't pay more than 1/2 of what a comparable new model would cost. For an entry level lathe that would cost less than $200 today, don't pay more than $100, etc. While you don't want to cheat her, don't cheat yourself either. (Paul Gruver) When it comes to wood lathes the tooling is the most expensive part of the deal. Depending on the quality of the chisels they can run from 20 to 100 each. Chucking mechanisms are quite costly so see what is included. A wood lathe has limited applicability in rodmaking (I said limited not NONE). The lathe itself is probably worth less than $100. (Ralph Tuttle) I bought one on Craig’s list a few months ago after watching them for a while. They will go for $80 to $200 depending mostly on how much the seller thinks they are worth. They are pretty simple and if the motor is good, it should work fine for rodmakers use. Unless it comes with a useful cabinet, I wouldn't pay more than $120 or so for a working unit. (John Dotson) Correct me if I'm wrong (it would be the first time TODAY), but weren't some of the older Craftsman wood lathes made by Rockwell? If this is one of the older Rockwells with the large bore through the spindle, I'd pay more than 100 for it in a heartbeat and wouldn't hesitate too much to pay 200 to 250 for it, assuming it a decent chisel set with it. Of course, if it's one of the later model craftsman with the flat face place and a small or no spindle bore... well, 100 or so would be a fair price. You can get a 3/8" bore 20" lathe from Grizzly for 170 or so, new. That's what I'm currently using. I think I have about 300 in mine with the 3 jaw chuck and tool set. If someone finds one of the old Rockwell/Craftsman lathes with the larger bore through the headstock spindle, let me know... I'll buy all of them within driving distance! The wood lathe I have now has a small spindle bore, probably 3/8" or so, and I'd love to have one with a 1/2 to 3/4" bore. BTW, Ralph is right! One good gouge can cost you more than a marginal quality used lathe is worth. But a $80 gouge is money well spent. VERY well spent. (Bob Nunley) OK Bob, time to brag a little. I went to an auction about six years ago and they had two wood lathes for sale. The first one went for $80. The other one had 20 chisels, face plate, 2 live centers and scroll chuck. Got it all for $200. By the way, it was an old Rockwell ¾” bore. (Ralph Tuttle) Thanks for all the responses. She brought in the manual today and it is one of the really simple lathes for turning long table legs and bowls. The spindle is a solid face with a screw fitting for attaching bowl and long stock. In looking at it I can't see that it would be any more valuable for rodbuilding than a hand power drill which at least has a chuck. I think I'll keep look for one that at lest has a hollow spindle that a rod blank can run through. (Larry Puckett) It would probably work a bit better for turning grips and reel seat inserts. You really need to check the tailstock ram. If it's solid, don't bother with it. If it has a Morse Taper, then it might be worth $50 to $100. While I do enjoy wood turning, I've actually found very few practical applications for it. All my tables and chairs already have legs. I have made a heavy wooden mallet and a few tool handles that I needed, but for the most part, it's just an expensive toy. (Paul Gruver) I definitely use mine a LOT, but my process is a bit different than most. I turn my reel seat wood and cork handles ON the rod instead of on a mandrel. Doing this, having a wood lathe with a bore through the spindle is a lot nicer than having to clean wood shavings/chips and cork dust off of my metal lathe. When I was turning these on my metal lathe, I discovered that wood dust and chips tend to draw moisture out of the air and do awful things to your ways and cross slide assembly on your lathe. If I had vacuumed it off every time I did it, probably wouldn't be a problem, but I didn't and get a lot of surface rust on my metal lathe. I don't worry so much about a little surface rust on the wood lathe, as I'm not turning things as accurate as reel seat components and ferrules on that. Another consideration is that I can just leave the 3 jaw chuck on the wood lathe. I run 5C collets on my metal lathe for everything. To chuck the rods up in the metal lathe, I'd have to have a small fortune in different sized hex bore collets. The wood lathe and tooling cost much less than a collection of hex collets. In any case, for me and the way I do things, it's a real bonus to have that little wood lathe in the shop. (Bob Nunley) I have one of those. It has a 3/4-16 thread on the spindle. You can get a 3 jaw for it for about $100 on eBay, maybe less if you shop around. It also has a Morse taper on the tailstock. I was able to find a live center for it on eBay as well for not too much money. I can't remember what the thru hole size is on the spindle, but it's not much more than 1/2 inch. They're on Craig’s list all the time for not much money. Wish metal lathes were. (Kurt Wolko)

I just got a Central Machinery 10x18 mini wood lathe. Hopefully decent enough for my situation. It came with only a 3 inch face plate (If I know the terms correctly.. My wife also bought, at my 10-year-old son's request, a set of tools for it (8 of them, 2 skews, spearpoint, parting tool, round nose, 3 gouges, Shopfox steelx brand, which are carbon steel right?) I reckon that I need several items to make my setup worthwhile doing the stuff I need to. I think I need to get:

Can anyone advise me of parts and things and where to go to get them? I have no idea what the tapers would be to buy parts. (Sam Nielson) Sam there is absolutely nothing wrong with that lathe and is more than adequate for grips and reel seats. The there are more than a few rod builders on another forum that use that lathe. It has a MT2 taper and the headstock spindle is 1" x 8tpi. Be prepared to spend more $$$ for accessories. I have a Grizzley 4 jaw scroll chuck (Vicmarc clone) for drilling out the wood spacer, I do 99% of my reel seat and grips using a live center in the tailstock and a dead center in the headstock which is called "turning between centers." I also turn my grips between centers (see here) and use 1/4" SS tubing to mount my cork and bark to turn my grips. (Ron Hossack) That's funny you ask. The same lathe was given to me, new in the box. I know it's a cheap lathe but I'll use it. I have a 4 jaw chuck already and I too need a drill chuck. If I remember correctly, this is the chuck I have and it fits. (John Smith) What do you intend to do with the lathe? That determines which tooling you need. (Harry Boyd) It may be wishful thinking, but if the lathe runs true, I will use it for reel seats and grips. (John Smith) I have the same lathe and it works well enough for turning grips and reel seats. I've bought some stuff from Penn State Industries and from Mudhole. I bought a 4 jaw chuck. But if you want to turn grips on the blank, you will want a 3 jaw chuck. I turn down grips on a mandrel. I bought a pen blank drilling chuck from PennState to bore reel blanks to fit on a mandrel. I've read a few places (maybe a website or the manual) that the tail stock is a MT1. It is a MT2....a little online looking shows the manual is correct. I bought mandrels for turning grips (1/4 inch) and one for reel seat spacers (3/8 inch). The 1/4 inch one came from Mudhole. The 3/8 one is a Lamar style mandrel and am not sure where I got it. I glue up the cork rings onto a 1/4-inch piece of all-thread. I glued them up on the 1/4-inch mandrel once.... never again. When I first got the lathe, I picked up a cheap MT2 live center and a cheap MT2 Jacobs style drill chuck. (Brian Greer)

|