Bamboo Tips - Tips Area |

|

< Home < Tips Area < Finishing < Dip Tubes < Finish Quality

Recently, I have been getting some very tiny bubbles in the finish of rods when varnishing. Between coats of MOW I am sanding lightly and using steel wool, then wiping with mineral spirits. Then I dry the sections with a paper towel. The sections look clean of dust, etc and seem dry. Yet. I am getting some very minute bubbles in some places. I use the dip tube method and withdraw the sections at about 4 inches per minute. Any ideas what could be causing the bubbles. Maybe I need to lower the sections into the varnish more slowly allow more time between wiping with mineral spirits and applying the finish. I think the bubbles will come out when I rub the finish, but the other areas of the sections come out looking like glass. Sure would like to alleviate the bubbles. Any ideas? (Ron Revelle) I thin MOW with mineral spirits. 10% for original formula, more for the new VOC compliant formula. Paper towels always leave lint, in my limited experience. Warmer is certainly better (to a point. You don't want to blow up.) Maybe try letting the sections set in the varnish longer before pulling them out and pull them out at a slower speed. Are you pausing for enough time at all the guides, guide wraps and any fancy wraps you may use? I've had a small cluster of bubbles below wraps or guides when I didn't pause long enough for the excess to run off into the reservoir. Can be frustrating. Sometimes it's the varnish and you just have to change it. Also, don't shake your tube up to stir the varnish after you first mix it. If you have to, turn it upside down once, sloowwly. There's all kinda crap that settles to the bottom, and foam can form and make a ring or thin layer on the top of the tube. Here's where using a paper towel is handy. Wipe out the scum and wick-off the top of the varnish. (Brian Creek) Some brands of paper towel contain silicone, which is bad for finishes and very hard to remove with solvents. Try microwave type towels. (Neil Savage) Probably air bubbles coming out of the guide feet tunnels, or from the masking tape on the ferrules, I get them all the time. Watch for them very closely when you are withdrawing the sections, I wear 3x magnifiers, have a strong light in the cabinet and keep a dubbing needle in hand at all times. Do whatever it takes to get rid of them. I stop at the top and bottom of every wrap and inspect for bubbles while I'm waiting, ones at the surface can be worked toward the edge of the tube and popped with the needle, if one gets past me and I don't see it until I've raised past it, I drop the section back in to the 1st wrap and make sure to get it before I start raising again. I have most of the bubbles on the first coat, after that, it seems the bubble producing spots are sealed and don't cause any more trouble. (John Channer) I'll hazard a couple of guesses. Are you mixing the varnish immediately before dipping each coat? I often turn my tube over a few times to make sure everything mixes together well. Doing so causes bubbles the length of the tube, and they are very slow to rise to the top. Guess number one is that bubbles from mixing are "grabbing" the rod section and causing problems. The solution is to mix your varnish several hours before dipping. Guess number two is that the sections are not completely dry from the mineral spirits. The sections really need to dry for an hour or so after wiping down. If they are still even the least bit damp, the mineral spirits prevents the varnish from adhering well and you get fish eyes <ask me how I learned that!>. For just a light wipe, alcohol evaporates more quickly than mineral spirits. It's also a much stronger solvent and will cause previous coats to get tacky if you're too aggressive. Also, there are many rags available much more absorbent than paper towels. I use a 3M finishing cloth as the last step before putting the rod section in the varnish. It's one of the micro-fiber cloths similar to those available in the automotive section at Walmart, and also similar to the new cloths for cleaning glasses lenses. Give these suggestions a try, and let us know what solves the problem for you. (Harry Boyd) I have been told (by a long time owner of a paint store) and I believe that it is not necessary to stir or mix gloss varnish before using no matter what it states on the can. For semi-gloss and satin it is necessary to make sure the dulling agent is well mixed before using. I never mix the gloss varnish in the dip tube. (Marty DeSapio) I agree completely. Varnish doesn't require stirring or mixing. Unless, that is, like many of us, you float a teaspoon or two of turp's or mineral spirits on top of the varnish to prevent it from skinning over at the top of the tube. In that case, the floating thinner at the top needs to be mixed in. (Harry Boyd) When I worked in chemical research, we used a vibrator to get rid of air bubbles in reactor tanks. I don't see why it wouldn't work here. (Rich Jezioro) I would suggest that you not wipe down the rod between varnish coats with mineral spirits. I wipe down my rod with rubbing alcohol if it has been hanging long enough to be outside the envelope for the time to apply the second coat but if under 24 hours (which is the outside the time limit for second coat on the varnish I use) I may not wipe it down. Alcohol does make less bubbles. Mineral spirits is oily and will hold it bubbles longer. (Timothy Troester) One suggested solution was not to use mineral spirits and use alcohol instead. Which I did and did not have a problem with the next rod. (Ron Revelle)

Mysterious Micro Bubbles No, not champagne.... Last weekend I started in on a new gallon of finish. It was time to change things out. Made a new dip tube, cleaned off two 3/2 rods, and dipped them. Although they didn't look too bad coming out of the varnish, once the finish was tack free, millions, maybe billions of tiny bubbles seemed to appear. When dry, the finish felt like very fine sandpaper. Started trying to eliminate variables. Sanded one section down, wiped with different rags and solvent in case the micro fiber rag was somehow contaminated. Dipped again. More bubbles. Replaced the brand new dip tube with another new dip tube in case I had somehow failed to clean the orignal tube thoroughly. Sanded a section down, cleaned again, brand new micro-fiber rag, and still another solvent.... more bubbles. Stripped all the finish off all the sections with 3M Safest stripper. Decided that perhaps the sealer I had used on these sections was reacting with the finish. More bubbles. Finally went back to read the directions on the finish can. Noticed the can was rather seriously dented on the side and the top. My current theory is that the finish itself, while in no way gelled over, has somehow been compromised before I received it. Any other ideas? Tomorrow I'll go back to the old dip tube and finish to try to get these rods done and out the door. (Harry Boyd) Was the varnish straight from the can, or did you thin with something. I had this when I thinned with Penetrol. I use MOW straight, but I've been topping off the tube with Old Masters spar marine varnish & haven't had a problem. Incidentally, I store my quart can in a vacuum sealed bag. Don't tell my wife I'm using her FoodSaver to seal varnish cans. (Ron Larsen) No thinners of any kind. Straight from can. (Harry Boyd) Well, clearly, going back to your old setup will eliminate some of the variables. Once you get these out the door, you can experiment further. Good luck. (Neil Savage) I had sort of the same thing happen with the last batch of LnL I got. I made a new tube and all that and let the new varnish sit overnight before trying to use it and had the same problem, full of bubble, but mine came in all sizes. I just figured it needed to sit longer, so I sanded the rod down past the bubbles and waited a week, it's been fine since. (John Channer) Currently I use Tru-Oil for my blanks but I had problems with bubbles while varnishing wraps with a brush. I use Epifanes and decided to thin it using Epifanes Brush Thinner which worked perfectly - no bubbles. So just maybe the problem is with viscosity of varnish or it just could be a bad batch of varnish. (Doug Alexander)

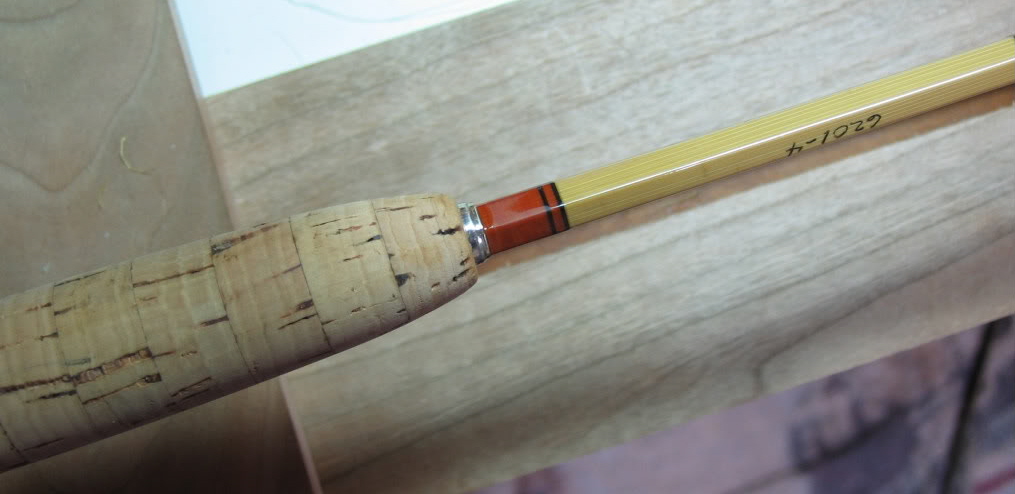

Yesterday I finished the dipping process on a new butt sections. After the first coat all looked great except for a pretty good sag on the winding check wrap. After allowing 48 hours to cure, I sanded out the defect with 1000 grit, wiped down with turpentine, and dipped the second coat. After second coat, the winding check wrap had large areas where the finish is dull (no gloss) otherwise it was smooth and even. Repeated the sanding with 1000 grit, buffed with 0000 steel wool, wiped down with turps and dipped the third coat. Results the same. Large areas of wrap have no gloss. I don't really want to add any more coats to the rest of the rod so I will probably sand it out again and hand apply varnish to finish it but I don't have a clue as to what caused this. the rest of the rod came out beautiful. Oh yeah, the varnish is MOW straight out of the can. Applied and cured at controlled 80 deg F.

(Rick Hodges) First off the rod looks great. Secondly I would put the rod on a turner and apply varnish to the signature wrap with a bodkin or a toothpick and leave it on the turner (turning) until it is dry. This is how I do it. Doesn't make it right but it works. (Joe Arguello) Several years ago I had a similar problem on the apexes of rods. I was "dulling" the finish between coats w/ 1200 grit. I discovered that the fine sanding wasn't allowing enough "tooth" for the next coat as I was also dipping at a fairly slow rate ( 2 in/min ) with thined and warmed varnish. I switched to 600 grit between coats and the "problem" went away. (David Van Burgel) I'm no expert on varnish, but I do have some experience with refinishing. My first thought is that the varnish wasn't quite cured and either had a reaction to the new coat of varnish or the turpentine. My next thought is that you might have sanded through the color preservative, and my final thought is that the varnish blushed. Some petroleum based finishes will blush if the finish is applied to thick or in humid conditions. Your rod does look great. (Wayne Caron)

|