Bamboo Tips - Tips Area |

|

< Home < Tips Area < Rod Design < Parabolics

Is it possible to design a 3-piece parabolic rod? I am a paraholic, but I'm not much of a taper designer. Most of the paras that I see are 2-piece rods, so I'm asking those who know. I'm thinking of making a 3-piece Driggs River Special and I am curious, will it work? (Hal Manas) My program shows the deflection of a Driggs River rod with two ferrules is only slightly more than with one ferrule. In fact the difference is the equivalent of only three more feet of line out. That doesn't account for the difference in stiffness at the ferrules. But like someone commented earlier about hinges: "It takes a significant change in diameter over several stations to make a noticeable difference in feel". The addition of an extra ferrule affects only about 2 1/2 to 3 inches of a rod, not the whole thing. That's my two cents! (Al Baldauski) Just looked at the taper. I think you will be fine with 2 ferrules fitted. The ferrules will fall on the two section were the rod has most backbone and not on the weaker spots. Go ahead it will be fine. (Gary Nicholson)

I'm currently making a Para 15 with tips for both wet and dry flys and that got me to thinking. What if anything would I need to do to the dimensions of the wet tip to make it a good rod for weighted streamers. Normally, I fish streamers with a 6 weight. Is it the increased dimensions of a 6 wt tip that makes it a better streamer rod, or the weight of line used for casting them? (Mark Lenarz) I have built the para 15 with only dry tips. The last one I gave to my father and we have both cast streamers with it no problem. IMHO I'd say leave the tips as the are -- maybe because the para flexes so deep it allows for heavier casting? (Don Peet) My Para 15 doesn't come alive until I've got more than 30 feet out on the dry fly tip. It handles weighted streamers real well from 30 +. Less than 30 feet and I need a 6 wt to get it to load even a little bit. (Al Baldauski) The Para 15 is a 6 weight rod. That's probably why it takes a 6wt to load it correctly! ;^) (Todd Talsma) I agree, the para 15 is a 6wt and hell, it fishes better up close with a 7wt, but all the taper info I find including that from which I built it call it a 5wt. (Al Baldauski) Hmmm. I don't think I've ever seen a 5wt Para 15. I went back and looked at the RodDNA database and sure enough. Some are listed as 5wt's! The one I made was the "PT Keller" version with the light tip and heavy tip. It's a nice rod, but I may have made it a little heavy. It really does cast better with a 7wt DT line! (Todd Talsma) It all depends on the water you're fishing. If you're going to fish those little rivers and streams of the east than you can fish those little light rods. If however, you're going to fish the big, and often windy rivers, out west, you'll need more muscle. Myself I wouldn't think of fishing a streamer with less then a 7 wt. You need to get the fly out there and down on the bottom. Also wear a helmet. (Mark Dyba)

OK, anyone wish to attempt this one. How would you go about designing a parabolic fly rod That's from scratch not from dissecting or copying one of the list. Any one willing to explain this. (Gary Nicholson) Do you have a definition of a Parabolic or can we make an assumption based on the fact that we HAVE SEEN “parabolic” tapers? (Al Baldauski) Check out Tom Faulk's design. A perfect arc will produce a perfect para (??) You can center the arc to place the thickest spot where you like. (Jerry Foster) A good general definition of parabolic action might be - relatively thin butt, relatively thick tip. (Bill Fink) I would say you would first have to write a set of specifications for the parabolic rod you are interested in. Since there is such a variety of Para rods already out there, one should have a good idea of what the end results should be. In fact any new rod design should start with the required specifications for that rod. I don't think that many people have taken this approach in the past, they may know what they are looking for in a rod, but have not write it down for all to view. (Bob Norwood) In fact any new rod design should start with the required specifications for that rod Hi Bob - I think you are right that the designer should have specific characteristics in mind. Here is a scenario for you to consider. This has been a back burner project that evolved in fits and starts over a few years, and I'm not telling the full story here for the sake of brevity. Basically, I was asked to produce a rod to the following specs: It is designed for bank fishing on larger spring creeks, and should cast a 3 weight line. It should be of a length and speed that would hold the line high in the air on false casts, and easily keep the line out of the weeds. The weight should be be appropriate for a 3 weight, so that the rod did not feel like a 5-6 weight casting a 3. It should load easily in close. The rod should false cast 50 feet of line. (The guy who wants the rod is a great caster ) To keep the weight reasonable, I decided to go with 8 footer, and hollow build. Not knowing of any such taper, I started out by putting a 3 weight line on an F.E. Thomas 4 weight 8 footer. It would cast the line a good distance, but it was obviously not loading properly, and felt too heavy for the line. Here's the Thomas taper, just for reference: 0- .062 For the first attempt, I decided to try a step down taper, figuring about .010 across the ferrules. I kept the Thomas butt, hollow building it, but designed a Garrison style tip to be built solid, slightly on the beefy side to handle the length of line. Here's the new tip. .062 It took a while, but I finally got the rod built late last year. It felt pretty good, and fished well, but I didn't think I had the 50 foot false cast, although the rod did cast further than most 3 weights without much effort, and did feel good in close. I thought maybe the step down was keeping the butt out of the action. Last weekend, I attended the Heritage Day the PA Museum of Fly Fishing, and met up with the guy who inspired the rod and watched him and a some other good casters cast the rod. All got about the same result, the rod cast very smoothly with 40-45 feet in the air, then just ran out of gas. Some other makers were watching, too. It became apparent that it was not the step down, the rod flexed through the ferrule but stopped loading half way down the butt. The butt swells significantly in that area, and the 3 weight line and tip just could not bend it, so the lower butt contributed nothing to the cast. Close, but no cigar. Starting at 50", here's what I would do the next time, feeling that the basic idea worked, I'm just going to significantly lighten up the lower butt, keeping the swell, but reducing it significantly. .204 Having fallen under the influence of Mr. Harms, and his cabal of convex taper theorists, I would also slightly rework the tip to: .062 All of this worked out with graph paper, not stress curves, although the tip stresses should certainly look familiar. (Tom Smithwick) This is a reply to Gary that I wrote last night before you posted your excellent description of a typical new taper design. Thanks for sharing this with us. Gary; How is it that you never ask easy questions? As I said, you have to write a set of specifications which would include not only the rod length and the line size, but also a description of how you want the rod to function. Is it for short or medium line casting or for distance or possibly all three. I think that most Bamboo fly rods perform one of these function best and are maybe fair at the other ones. Do you want a fast rod or do you like one that you can feel the flex it the tip or in the handle or maybe you like a rod that has a flex area in the middle. You have suggested a rod like a Paul Young Parabolic, well not all of his rods are of this design. Take the PY Smidgen a one piece 6 ft 4 wt rod with a soft tip for short accurate casting but it still is strong enough in the midsection to cast a medium long line. The Midge is not a parabolic either, nor is the rod called JJ's rod. He did make a lot of different types of parabolic, but even the rods of the same name have slightly different tapers So I think that you have to define the purpose of the rod quite accurately before you can even start to develop a rod that will perform in the way you want it to. I have found that rod design is not an easy task that can be done in a short period of time but more of something that develops over a period of time as the concept is slowly formed into a design and then it is modified until it becomes the actual rod taper you have been seeking. Then, when it is made and evaluated and perhaps modified again and again until it finally becomes the rod you have been looking for. Sadly, only to find that someone else has designed it long before you; joke joke. I do not mean to make light of rod taper design; only to point out the many difficulties one must overcome to achieve a new and lasting one. there are precious few of us who are brave enough to put forth our designs for the rest to view. More of us should do it more often and the rest of us should be more tolerant. (Bob Norwood) P.S. Now after all of this if you really want to attempt a parabolic rod design and can specify it more closely, I would be delighted to try it. I must say that I have never designed one, but will not let that stop us from trying. After rereading your account describing how you went about designing a new taper I went back and looked at a rod I am in the process of building for a friend. He wants a 7' 4 pc 3 wt for back packing in the Smokey's here in Tennessee. When I looked at your third modification I realized how close our tapers were. Mine has a little softer tip and a larger flex area in the butt; (no step either) with a butt swell that's very similar to yours. Isn't life interesting ? I think the ferrules will stiffen my design a bit, but hope it will be to his liking. 62 ferrules back packing in the Smokey's here in Tennessee. Hmm, Yes, there are a lot of similarities. The tip does look soft, but plenty of meat in the taper behind it. It should be a good small stream performer with a 3 weight. I suspect a #2 might just load it, too, for a faster action. Let us know how it turns out. (Tom Smithwick) Interesting taper.. but one question. After several conversations about how to use Garrison stress curve math, I see that at 50' your stresses are in the 260k range. This seems to exceed the Garrison limits you are so adamant about. What happened to 200-220? (Jerry Foster) For smaller short distance rods , ones that you want to have tip action at short line lengths I use this design. In these cases I disregard the max limit. At longer line lengths the rod will straighten the tip when loaded any way. The rod is really just for 5--20 feet fishing although you can put out more line when you need to. The 200,000 +- limit is very good to use in most cases as a design point at 50 feet of line, however you automatically pass this when ever you use longer lines. This rod with the softer tip allows the rod to have tip action only, just a flick of the wrist is all that you need and for small streams that exactly what you want. (Bob Norwood) Your rod seems to stress well at 35' which is probably a good design distance for a 3 wt. (Jerry Foster) Just for fun using my Excel method this is what I came up with for the Thomas 8’ 4wt Para 0 .062 It’s certainly parabolic but it looks way too stiff in the midsection and that’s only based on what I know of a PHY Para 15. Your taper looks like it will handle a 4wt ideally at about 40 feet Those are my guesses. (Al Baldauski) Larry Blan should jump in here as he is a true para aficionado. A couple of perceptions: The best example I have seen of a pure para shape is the Young Para 14... your rod is close.. One of the keys to a good pure para is that it flexes under the grip.. Beginning at 76" you have started to increase the taper again which will stiffen the butt a lot and may create an unwanted hinge at that point (76") And as Al stated the mid may be a little too stiff, almost in the non flexing range.. Your rod has a very flexible tip.. short vertical stress But you will only know how close your target you are if you make it. Remember that Parabolic is just a word that a bunch of drunks thought up by a campfire.. They really aren't a true parabola. Those guys didn't use stress curves so the name was derived from looking at a graph of the taper dimensions. I will disdain from giving you, or anyone, advice on how to make a taper, as my taste in rods may be very different from yours. (Jerry Foster) Blan should jump in here as he is a true para aficionado. Interesting exercise Ken. I have never designed a parabolic, and prefer other tapers for most fishing, but I do like to cast them. I have looked at a bunch of tapers over the years, and also thought you might have gone too far with the convex curve, particularly in the tip. Here I have flattened it out a bit, moving the apex of the curve back a little and reducing it a bit too. I also was confused by the butt swell, and flattened that out as well. NO ONE should built this taper without getting it checked out by a certified (certifiable?) paraholic. I just offer it as part of the discussion. I'd like to hear from some of the para guys, too. 0.062 Your deflection curve compares more favorably with a Para 14 but it’s still a little stff in the midsection. I think it would feel real hingy near the grip. It looks well loaded at 35 feet with 4wt line. (Al Baldauski) That looks more like it Tom. (Gary Nicholson) I've posted FlexRod images of Ken's original taper, Tom's revised version and a Para 14 on the blog. Click on the images to review or save the charts. If you've never seen a deflection (bent rod) chart you might find the summary chart interesting. Also, take a look at the bent stress curves for these tapers. The detail images include sectional charts as described by Bill Harms and Tom Whittle in Split & Glued (see chapters 8 and 9). FlexRod can be downloaded from the blog if you want to play around with the charts. Here's the link to the post. (David Bolin) Good work Dave Which brings up the point of where each of us prefers the tip rollover point. (Jerry Foster) On the point of parabolics anyone have any experience of hollow building Parabolics. Without destroying the action of the rod. (Gary Nicholson) Yes...though not personally, and only indirectly. Adam Vigil posted here several years ago about a nodeless, hollow built (I think), para 15. It exploded. (Mike Shay) Cool stuff. I still don't understand peoples facination with the swelled butt..... (Jim Lowe) The swelled butt contributes a nice line in the transition between cane and cork. Additionally, it verifies that the section has been designed for the rod, instead of simply being cut to length from a one-taper-fits all blank (the latter, being what most production operations have done). (Bill Harms) There are swelled butts and there are swelled butts and there is more than one reason for doing them. If it's a fast swell more than .020"/5 in. then usually it's just before the handle and stops the rod action at that point. Then there is the slower swell that gently builds into the handle over 2-4 stations; this is to allow the rod action to move further into the swell before stopping as the rod is loaded heaver. Then there is the flex area just before the butt and the swell at the butt to stop the flex action before the handle. Then there is the small swell that may or may not accomplish what the designer intended. I'm sure there are many other reasons that I have not listed; but, the swell is to complement the rod action that the designer is trying to accomplish in his design. Some times it works just as planed and some times it doesn't. If you look at all the different tapers that have been designed, then you start to realize that new designs are very difficult to achieve. All of Everett Garrisons tapers that I have seen have a swell just before the handle. He is the only designed to use the same design for all of his rods. (Bob Norwood) Bob says, and I quote, "If you look at all the different tapers that have been designed, then you start to realize that new designs are very difficult to achieve." Hear! Hear! I couldn't agree more. I build a rod which I claim to be of my own, original design, a 7'0" 4 weight. But in reality, while the numbers have been quite independently arrived at, I am sure that they do not vary significantly from several other tapers, equally the brainchildren of others! It may be that when you move into the realm of the CNC mill, with its far greater inherent variability, you may start to break new ground. However, I seriously doubt whether I would be capable of detecting those subtle differences based on 1" centres. A very old question - how many thousandths of an inch represents a palpable action change in any given thickness section? (Peter McKean) how many thousandths of an inch represents a palpable action change in any given thickness section? I think that depends on whether you are talking about a localized variation, or a consistent reading along the rod length. It also depends on where the variation is. A .003 variance in the first couple feet of the tip will amount to 1/2 a line weight and certainly be noticeable. The same error in a butt section would hardly be noticed. I have always thought it more useful to think of tolerances in terms of percentage of thickness. Basically, I think if you are within +/- 2%, you have built the rod you set out to. More than that, I think there will be significant differences, but, there are a lot of variables, so that statement can't be carved in stone. (Tom Smithwick) I agree, sort of. Thinking in terms of percentage change in diameter is most accurate. But an analysis of deflection based on a change of 2 ½ % along the length will change the rod by 1 whole line weight! Certainly, localized changes are much less noticeable. A 2 ½% change in the top 25 inches of a rod will stiffen the tip somewhat and make a difference in close but the overall action won’t be changed. On the other hand, if you change the bottom 25 inches of the action length by 2 ½% you will experience about a ½ line weight change in stiffness and that will be felt. (Al Baldauski) Peter said "A very old question - how many thousandths of an inch represents a palpable action change in any given thickness section?" OK, I would like to hear answers to that question and the following ones: Do you mike your tapers after you have made a rod (before and after varnish as appropriate) and compare them with the original taper specifications - How close to the original taper are you along the length of the rod? What is the deviation pattern along the rod length and is that consistent rod to rod that you make? Just how much difference does one have in taper dimensions as designed and as miked?? What rod dimension tolerances do you try to maintain along a rod length? Now if we can answer these questions we might have a good handle on rod manufacture let alone rod design. (Frank Paul) I measure the strips as I plane them with my digital calipers them wrap the rod up temporally and measure again. Any differences I get I adjust the forms to size. My finished rods average within about 2 thousandths either way. (Gary Nicholson) Frank, you ask a very good question. Do makers mike their tapers on finished rods and compare them to the original taper specifications? And I did not notice any replies on the list to this question or your other questions. I've miked a lot of rods of various pedigrees and the results raise some doubts in my mind. Of course you must believe that my rods all come out within one thousandth of target spec at every station. (Bill Fink) I guess that I didn't get Franks post, some time that happens, but at least I did get it roundabout through Bill, thanks. I do measure every rod that I make and check it against the design taper. Most of the time it comes pretty close and if not I build another section that does. My reasons are personal, I want to know how a particular design works and compare it to my other designs hoping to make that all elusive perfect rod. Of course it never happens, but I keep on hoping maybe one day it will. (Bob Norwood) I understand the reasons folks give for adding a swell. What I don't understand is how folks say " build such and such a taper, you'll love it, but don't forget to add a swell." It's always seemed pretty random to me. As if any random swell improves the rod but doesn't affect the character of the rod. To each his own obviously but it simply seems pretty random. It seems to me if you add a swell to a rod that wasn't originally designed with that in mind, you end up with butt section that's out of balance with the tip. I know that presumes that folks attempt to design a rod with a particular function that is also in balance and that's not necessarily the case. :) (Jim Lowe) Interesting, isn't it? We see the same over here -" Make sure you put a butt swell in the rod, won't you?" I have thought about it a lot, and this is my conclusion - a lot of buyers of bamboo rods do so for reasons of being cool, and, as they say, because "I think it is about that time in my angling I moved up to a bamboo rod".. They REALLY like the feel and the weight of graphite rods, as that is where their experience lies. So the more a bamboo rod resembles a graphite the more they like it. Hence the butt swell - puts all the real weight back at the hands where you can't feel it much, and stiffens up the action and speeds the recovery immensely. I made a 7'0" 4 weight once just to see how much swell I could cram on with my forms, and it was a monster. I couldn't find a line to make it load, Sir Lancelot du Lac would have jousted with this stick. The first bloke I gave it to to try was a real poseur of rods, and guess what - he loved it! There was nothing to love! No feel, no action, no rhythm, no nothing! Just stiffness! (Peter McKean) I believe by definition a Parabolic rod design describes the stress curve of a rod which has a parabolic curve to it. Therefore by using a simple Excel file to plot the rod dimensions and converting it to a simple stress curve. Once you have the basic design you can simple adjust the stress curve points to change the rod dimensions to get your parabolic rod. It's actually quite easy. Now all we have to do is define what a parabolic curve actually looks like. (Ken Paterson) Tough design criteria. Other than for the fun of it, I don't think 3 wts. were meant to do this. Short is easy, long is easy, but the middle range 20 to 30 ft. might be never, never land. I'd tell the gentleman to use a 5 wt if he wants to aerialize 50' of line. Heehee. (Jerry Foster) how would you go about designing a parabolic fly rod Hi Gary - I think you have to start in the middle, the one characteristic they all seem to have in common is one ferrule size larger than you would expect on a progressive or straight taper rod of that length and line weight. It seems to me, however, that designing a parabolic from scratch is a tricky business. If you consider the two leading parabolic designers, Young and Ritz, It seems that both made many prototypes before settling on the final designs. I don't think the tip area presents all that much problem, I suspect the trick is getting just the right balance between the flexible butt, and the stiff middle. Not enough flex, and all you have is a fastish action clunker with too much weight in the middle, too much flex, and the rod won't cast at all. I would not personally attempt to design one without looking at a bunch of similar tapers. Why do you want to start from scratch? (Tom Smithwick) Someone in a previous conversation had referred to a "parabolic stress curve". I was just trying to say what you said except I guess I used the incorrect verbiage of "taper dimension " instead of the correct wording, "empirically." However whether anyone likes stress curves, or deflection, or linear taper graphs, or graph paper, they all reflect the same shape. I wasn't trying to say that a Para 14 is the best rod alive, simply that the shape of the curve was a good example of a para. I also agree that all rods are defined by the caster, no matter the shape. (Jerry Foster) I had the opportunity of casting a number of Rods built by Paul Young. I liked the Para 14 better than almost any other rod he made. Roger Barrett offered to make a Para 14 for me in exchange for my Henry's Fork. He made an absolutely unique rod of great beauty and design. I am writing an article about it for Power Fibers. (Ralph Moon) Look on Frank Stetzer's web interface to Hexrod under "start with a classic rod taper" and go to the Para 14 posted by George Maurer. Look at the stress curve. This is what a para stress curve should look like in my humble opinion. It's the "double bump" stress curve that someone mentioned the other day. Notice that the rod is a 7'-9" #5 yet it has a heavier tip than either of those submitted and a smaller butt. In the middle it is almost the same as those. The dimensions graph to a smooth curve showing that it is thick in the middle and falls off toward the butt. It seems to be divided into thirds. Years ago I saw a photo of Charles F. Orvis putting a curve into a rod to show that it curved in a parabolic shape. The rod was attached to a board on the wall and he was adding weight to the tip or a line through the tiptop. I always assumed that this is where the term parabolic rod came from. I could be wrong about that, we all know what we do when we assume. This is copying an existing taper, I know, but it is a good example of what we should be shooting for. I like to go for a slightly heavy tip third, a heavy middle third and a bit of a light butt third. This makes for a terrific rod to cast in close and still have the ability to cast a good long line if necessary. It also does most of the work for you. That's another benefit of the para taper. If you learn to slow down your cast the rod will really help. When I am working on a taper for myself I always put it into Hexrod and look for that "double bump" stress curve. (Hal Manas) In the event that we might be attaching to much to the meaning of a name, I believe that the designation of a rod as being parabolic came from Charles Ritz. On p. 64 of the revised, English-language version of his book, "A Fly Fisher's Life," he writes, "This is the action which I have called 'Parabolic', though the term is only a figure of speech, and the curve of the rod has absolutely nothing whatever to do with a parabola. This name used commercially dates from 1937." (Tim Anderson) If you thumb through the Garrison book, you'll also find a story about Ritz and someone else asking Garrison too look at a rod they had overhauled. As the story goes, it seems the rod was caught in a delivery boy's bicycle spokes and shortened at the tip and butt. They put a new seat on it and remounted the guides and found it would now cast a country mile. The book gives Garrison the credit for coining the expression "parabolic". (John Channer) You are right. The story by Garrison on p. 238 in Hoagy Carmichael's Garrison book IS about Ritz's broken-tip rod and the episode occurred in 1934 in Ritz's presence. The relevant part of the story is: "So, Jack Knight was so thoroughly impressed with this thing [the rod] and the feel of it he wanted to give it a name. I mentioned the fact that if you just took a plank of uniform thickness and stiffness through its entire length and anchored it into a brick wall so it couldn't move and put a weight on the end of it, its stress curve would be a true 'parabola.' He said, 'That's it. This is the 'Parabolic Rod.'" So was it Jack Knight or Garrison or Ritz who coined the name? Ritz may have been the first to use it widely, but that would be hard to document now that the people involved are no longer with us. Nevertheless, my point remains the same. The name itself probably means less than we would like to think. (Tim Anderson) You are most likely correct about the name, but my point is that the tip needs to be a bit stronger than the two examples that we had and the butt needs to be a bit weaker in order to make it all work really well. If it is done correctly it does indeed work really well. (Hal Manas) In its simplest form a parabolic taper would be a straight line taper with more material added to the middle of the rod. How much more material you add and whether you shift it off center to the tip or butt would be further subtle variegations of the parabolic taper. (Will McMurrey)

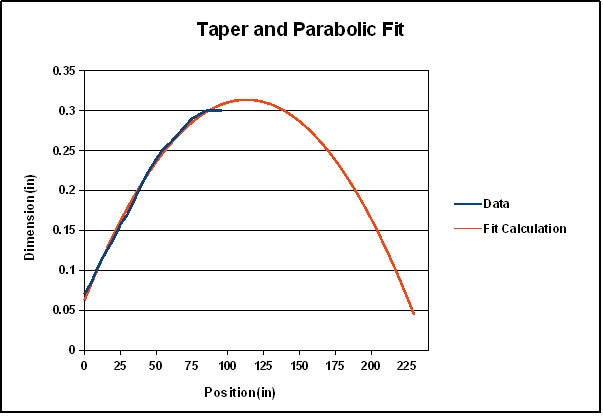

I've just finished out a para 15 clone and while it's a good rod for big fish. I'm thinking I'd like something a little more parabolic and suited to medium rivers. Has anyone tried this and how did it turn out? To get more fish fighting ability and retain the parabolic nature at the same time I took a slightly beefed up Para 14 taper and extended it about 5" to give it .300 above the grip. It looks like this:

(Bill Walters) You don't want a thicker butt to get a more parabolic rod, that is with action clear to the butt. That would diminish it. I'd would stay pretty much with the dimension at 90" for the next 5". Now I haven't actually done this with this particular taper, but having built a number of parabolic rods, doing similar things, that is my suggestion. (Mike McGuire) I'm realizing that I wasn't real clear on the intent. What I did was take an existing Para 14 taper and run it through hexrod and extended it 5". What I meant by more parabolic, was more parabolic than the Para 15. Extending it 5" is an attempt to preserve the action while increasing the diameter in front of the grip to make the rod better for mending line and landing fish. I'm trying to come up with a good balance between feel and utility. (Bill Walters) If you want to clarify... What exactly does the "parabolic feel" mean to you?Most people describe parabolics as having a kick.. Why do they kick? (Jerry Foster) Overswing. All that wood way out there turns over and "kicks" back thru the relatively lighter butt. Charles ritz described it as "an apple on a stick" (Chris Obuchowski) Among rodmakers who understand tapers there is only one accepted definition of a Parabolic rod. A rod which is stiffer in the mid and softer in the butt than a linear rod with the same tip, butt dimensions. As was pointed out to me in several PM's, this (see above) results in a rod which unfurls, springs, out of sequence. The mid of the rod straightens out first, then the butt, then the tip. The result is the feeling of a punch or a kick.(Jerry Foster) I am in agreement that Para is just a marketing term, but by the history you pointed out (- Paul Young) it (the name) now has an enduring legacy. As such, it now has a specific meaning. If someone says a rod is parabolic and, if it is truly parabolic, you know what to expect. Bill Walters started a discussion on Clarks a while ago about rod naming conventions. The only agreement was by a few people that thought fast, med., slow was adequate. How mundane. How tupperware. Although it is part of a rod's nomenclature it is not enough to properly describe a rods character. Now, you have in the past and present made a couple of broad brush statements that I think need a little more discussion. That 6 sided rods are the epitome of fly rod shape. What possible evidence do you have to make that claim? That there is only one kind of taper required for fly rods. Over the last 10 years or so I have placed a dozen rods or more on the ground for people to cast. I have done this at various clubs and rodmakers gatherings. Probably more that 1,000 people have cast these rods and there is no consensus at all which is the better rod. (I fully recognize that I don't have the knowledge or skill to make the best rod.) There is an agreement as to which is the worst. These people range from beginners to experts. I, however, have noticed a pattern that people seem to select a rod based on their individual biomechanics. Certain tapers seem to naturally fit peoples individual casting style. My point is that we, as makers, seem to get all hung up on rods that WE like and loose perspective. We should be making rods that individuals like. (Jerry Foster) It's true that parabolic became a marketing term but the overall story is interesting and has an irony. The use seems of go back to this meeting in 1934 between Sparse Gray Hackle, John Alden Knight, Charles Ritz and Everett Garrison recounted in chapter 14 of A Master's Guide. Ritz was showing off some kind of rod perhaps with this para kick characteristic. It was apparently not to Garrison's taste, and he made a snarky comment that the stress curve of broomstick was a parabola. The insult went over Ritz's head, but he liked the word parabolic and adopted it. He became associated with the French rod company Pezon et Michel around that time, and not long after that they came out with rods with "Parabolic" as part of their names. You can read about it at this link. Interestingly, the A and C tapers of E.C. Powell are all exactly parabolas. If you fit a parabola to them, you will come up with a correlation of 1.0. However, his A tapers are concave upward, while the C tapers are concave downward. Rods that are described as "parabolic" have tapers that are concave downward. But I don't think E.C. ever used the term parabolic to describe his C tapers. I gave a presentation on just that aspect of the Powell A & C tapers at ESRG in 2011. I have had a page up on it on my web site since then. I don't think any of the classic makers of parabolic rods knew that the tapers were parabolas. As to the difference between a parabolic curve and a circular curve, I find the the fit of say a Para 15 to a parabola pretty convincing.

It is possible to get a high correlation fit of a straight line taper to a parabola. However, when one looks at it, it is a fit to a short section of a parabola far away from where it curves much, where over the length of the taper it is almost indistinguishable from a straight line. Claims about correlation do have to made carefully. One does have to look at the picture. See Anscombe's Quartet. (Mike McGuire) If memory serves, Powell, in his pamphlet on casting dynamics, referred to the A taper simply as butt resistant and the C taper as tip resistant, with the B taper as an implied straight line middle ground (he never gives the B taper a name label). (Chris Moore) That is true as far as it goes. Here is a link to the pamphlet. Obviously in 1937 when Powell wrote it, he wasn't going to give away any secrets. Now there is more information out there. Ed Hartzell in the Nov/Dec 1998 Planing Form (and republished in Best of the Planing Form 2) wrote an article with the details which led me to the conclusion that the A and C tapers are sections of parabolas. (Mike McGuire) The Powell A B C System is really not about three different types of tapers, it's really only one formula with which you enter numbers to get a taper that is either Straight, by leaving off the second number or has an upward curve by adding a second positive number or has a downward curve by using the second number as negative. So as you can see it's all about choosing numbers so that you get the type of Taper you are looking for. You can't specify a POWELL TAPER by just choosing a number A B or C, you must also give 1/2 the Tip value, 1/2 the 6-inch station increase value in thousands (this is the number people use to describe the A, B, or C taper) and 1/2 the second 6-inch station increase as a fraction of a thousandth of an inch. Starting at the second (or the 12 inch) station. You can make the A Type Taper look like the B Type if you just choose the second number small enough so that it doesn't really matter. It's all about choosing the right numbers.You will find that most people when they specify a Powell Taper do not give all the necessary information such as the tip value which is absolutely needed to get a usable taper for the line size you would like to use. I have tried to find some actual Powell Tapers that were made by Powell, if anyone has some they would share I would appreciate it. I got into all of this Powell Taper thing a couple of years ago because I kept hearing them mentioned and I knew nothing about then. I now have one of my spreadsheets converted to just the Powell Tapers. You only have to enter the 1/2 tip value and the other two numbers for the 6 inch stations and you can see what the taper looks like when plotted on a 5-inch Graph and modify it anyway you would like to get a taper you feel you could use. If anyone would like a working copy just let me know. (Bob Norwood)

I've always wondered, what are the advantages, or what makes a parabolic taper different in regards to feel? (Scott Bahn) Since no one has answered your question, I'll take a shot. A parabolic taper has its principal flex in the lower third of the rod and a secondary flex in the upper third with the middle third the least flexible. As a result, you get a double kick; first when the lower third unloads and second whet the upper third unloads. This usually results in longer casts. The main complaint is that it isn't much good for shorter casts but I have made parabolics with a softer than normal tip that do short casts quite well (the softer tip also makes it " easier" to throw tailing loops). As far as feel goes, for me the feel is similar to that of a full flex rod but the casting stroke is a bit faster. I recently made a 5 wt and a 7 wt with a slightly heavier tips which throw a nice tight loop and are really good in windy conditions. (JW Healy)

|