Bamboo Tips - Tips Area |

|

< Home < Tips Area < Tool Building < Ovens < Wiring

I was given two 30" strip heaters (220v 1000w). Is it possible to set them end to end wired off the same control to make a 5' oven? Would they heat evenly? (Dave Kenney) If you wire them end to end, in series, you will only get 500W of output, not 2000W. If you wire them in parallel you can get the full output. They can still be mounted end to end, though. You should also consider the heated area of your oven. It is very possible to have strips that are too large for your oven, just as it is possible to over-insulate. (Martin-Darrell) You can wire them end to end. For 220 volts, BE SURE to wire the strips in parallel and hook up to a 2 pole breaker. The heating will be even as both heaters will draw the same wattage (1000). Use a 20 amp breaker. (Jim Bureau) I have a similar situation. I have 3 heater strips I got from Russ a couple of years ago. They are 18" long, 750 watt, 120v each. I also have the guts/controls out of a 220v range/cooktop. I don't know how to wire-up the strips, 120 or 220? I think the first thing to do is notify the fire department. Any ideas out there? (Don Schneider)

I need some help. I am in the process of building the duct work oven with the mica strip heater. Now not being good at all with electrical wires and the such, I was wondering if there is a site that gives detailed instruction on wiring strip heaters or can anyone give advice on the process, if it is a simple one. I have checked the tips site and have not found wiring instructions. I have also checked the list's archives and there too have been unsuccessful. Any help would be greatly appreciated. (Robert Cristant) I saved this info from my oven of the same type: Surplus Center catalog, they have listed on page 147 an Oven Thermostat Control, Item No. 11-2192, New, w/60" capillary tube, 150 degrees F to 500 degrees F, rated 15 amp at 240 volts AC, instructions included, 3"x 1" x 2", all for the low price of $12.95. Sorry, no URL, but the phone number is 1-800-488-3407 FREE. They have many electrical motors, switches, hydraulics, gas and diesel engines, winches, etc. Call for a catalog. I have a diagram of the wiring for this item. It works with my mica strip. The next oven I make will be a convection heated air oven with a variable control heat gun. I do recommend you look into it before you invest. (Rex Tutor)

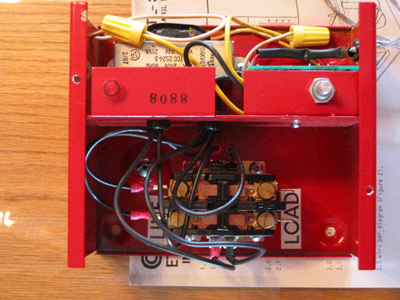

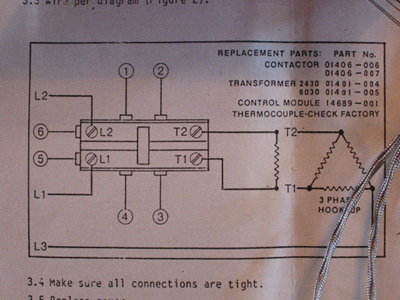

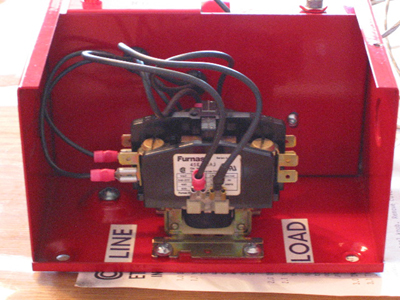

I just got a Chromalox temp. controller from Ebay for my oven. I figured for $10 I couldn't go wrong since I can dial in the temp I want and it comes with a thermocouple wired in. In any event, it's better than what I have now. Not as slick as those PID units that some of y'all got going, but I think this will do until I can build my dream oven. That said, I don't want to fry myself or my oven on my first attempt to hook it in. Not being a whiz at electrical gadgets, I was hoping someone would be willing to give me a bit of advice. I'm wondering where to put my 240 lines in and where to attach the leads to the elements. It seems like the power goes to the Line side (L1 and L2) and the leads go out from the Load side (T1 and T2). But, I'm not certain. And what about the other six terminals shown in the diagram? They seem to be in use, but I don't know if I should do something about them. Oh, yeah... what about grounding the thing? Can someone enlighten me a bit? Here are the links to the photos of the unit. the last link is the diagram.

Questions or comments would be greatly appreciated. (Jason Swan) I don't have first hand experience with that controller but from the pictures and schematic your assumptions are correct. L1 and L2 are the input connections. T1 and T2 go to your heating element. All of the other control wiring is taken care of for you. Ignore the other terminals. It is always good practice to run a ground wire to the metal frame of your oven. There's nothing in your pics to verify the voltage so I'll assume you have read on the device that it's designed for 240 volts and you, therefore have a heating element rated for 240 volts. If it's rated for 120 volts and you apply 240, you'll blow your control transformer. Oh yeah, speaking of blowing things and good practice, you should also include a fuse in each leg of your 240 volt lines. Just looked at the picture again and I can read 240 volts on your control transformer label so that's the right input voltage. (Al Baldauski) Al is correct. Line goes to L1, L2 and the element goes to T1, T2. Before connecting the element to the T1, T2 connections, I would plug in the power and rotate the knob and make sure the contactor (relay) pulls in (makes contact). You will hear a definite click. You did not show the other side of the control box, so I have to assume that the transformer is connected to the thermostat and the sensing bulb (You called it a thermocouple). You could try an experiment and set the thermostat to a temperature that just activates the relay. Then put the sensing bulb in some boiling water. The relay should deactivate if the boiling water is hotter than the setting that it took to activate the relay. If this works everything is working as it should. (Dick Fuhrman)

Gang, before I set this project aside, maybe some one can shed some words of wisdom. I attempted to build a oven using a 8 ft electrical wall heater element. I did not remove the fins but I did gut what I thought was the thermostat and directly wired the element. I also discarded the supporting structure of the heater. I mounted and boxed the whole thing into 8 ft of 12x8 ducting and fired it up. The highest I could obtain in 30 minutes was 168 degrees and then it appeared to shut down. Would appreciate any constructive comments on success or failures. Could there be a thermo overload protection built in? (Jim Tefft) I built my oven with a heating element like you'd see inside a kitchen oven, only mine is straight. It's 60" long/.430 diameter and rated around 2200 watts, 220 volts. It takes about .5 hr to bring it to 350 degrees in my cabinet. Id say you did good with a 1500 watt element to get the temp to 168 degrees. I'd guess that since the wall heater was built to some UL code it was made to shut down before overheating to a flammable situation. (Chad Wigham) Not necessarily true. My convection oven has 1500 watts of heater elements in it, and I can take mine well over 400º easily in less than a half an hour. (Mark Wendt) I'd have to think there is a thermal cut out on a wall mount heater. Otherwise, if the thermostat should stick it would get hot enough to start a fire. My heat gun oven gets to 350 degrees in well under half an hour, although the first one I made (out of regular furnace duct) wouldn't go above 200 degrees. (Neil Savage) Are you connecting directly to the ends of the element? Is there anything else between your cord and the element? Was the heater rated for 220V or 120V and what voltage did you connect it to. What is the wattage of the element. I am not sure what UL requirements there are on baseboard wall heaters as far as temperature they can achieve with out some kind of limit. A 4500 Watt Kitchen oven element straightened out might be a better bet. Make some supports out of music wire or sheet metal. Those elements are rated for 240 Volts and at 120 volts will draw about one quarter of the rated wattage, thus a little over 1000 Watts. (Dick Fuhrman)

Here's a question for the electricians among us. If one wired two, 220v strip heaters rated at 1000 watts each, in series with 110v would one end up with 1000 watts output? Would wiring them in parallel produce 500 or 1000 watts? Wiring them in parallel would provide equal voltage to each strip without the voltage drop you might experience if wired in series. (Wayne Kifer) Well, lets see... if I can still add then: R=E(Squared)/W so R=48400/1000, or 48.4 ohms for one element In series, that would give us 96.8 ohms of resistance P=V(Squared)/R so P=12100/96.8 or 125W @ 110V In parallel: Rtotal for 2 resistances = R/2 so R=24.2 ohms Again, P=V(Squared)/R so P=12100/24.2 or 500W @ 110V (Larry Blan) Putting 120V on a 240V 1000W heater strip would give you approximately 250W output. I'm not sure what you would get putting them in series. Putting two 1000W 240V elements in parallel would give approximately 500W output of heat. 3.1413 x 500W = 1570 BTUH You could probably run this on a 20A 120V circuit. (Dick Fuhrman) If I remember right, you can run approximately 1800 watts on a standard 120 volt 15 amp circuit. A toaster or broiler oven run about 1200 watts, so 500 certainly shouldn't be a problem. However, if you're going to the trouble and expense of making such an oven, why not get a 240 volt circuit put in? It's easy enough for an electrician if you're not comfortable doing it yourself. (Neil Savage) Thanks for the help guys. 500 watts seems a bit underpowered to get the temps I'm looking for. I can't remember what the wattage is on my heat gun. Next question. Would an oven thermostat and controller do an adequate job of maintaining a temp within a couple degrees plus or minus, or would I need to go to a programmable controller? Also, what's the ball park cost on a programmable unit? (Wayne Kifer) If you're looking for temperature control plus or minus a couple of degrees, a typical oven control won't cut it. The best way to do that is with a PID controller. You can pick them up on eBay usually for less than $50. Brand new can be a bit pricey. (Mark Wendt)

Well I’ve finally bought the parts for a heat treating oven. Could I get a little advice on how to wire it. I got the 54” mica strip, 650 watts, the thermostat and high temperature wires. I bought a 9’ 16/3 cord. The thermostat has two connecting pins and two screws labeled 1 & 2. Do I put the black and white wires from the electrical cord to the screws labeled 1 & 2 ? I think the pin connectors go to the mica strip. Has anyone done this and offer any advise. Electricity is not my forte.’ I would appreciate any advice. I’ve been using a heat gun oven but after the last time I really became frustrated by the drop of temperature when I opened the door to insert the strips for heat treating. (Gary Young) I don't know what kind of controller you're using. It could make a big difference. Normally the white neutral power wire connects to the white heater strip wire. The black power wire connects to pin 1 and the black heater strip wire connects to pin 2. The controller then acts similar to a light switch using a thermocouple to sense the temperature and control the switch. Does your unit have a thermocouple? Where do the thermocouple wires connect to? I think we need more information on your system. We don't want to electrocute anyone. (Ken Paterson) An update on this issue: I found a heating contractor to make the duct work, but I didn't think to ask them to not put the bend on the ends for connecting two pieces together. I was able to wire it as per you instructions, but It took me two weeks to get up the nerve to plug it in. I'm not that comfortable with things electric. I need to make sure I'm getting the temperatures I need and adjust the thermostat accordingly. (Gary Young)

What size wire should I use for wiring an Oven Digital Temperature Controller and the Relay? The heat strips are 700 watt 120 volt. I would like to use the smallest possible. (Lowell Davis) 16 gauge stranded wire would be your best bet. You could go to 18 gauge but the smaller the wire the easier it is to "pinch" a connection or otherwise break it. (Al Baldauski) And around ovens, I'd go for high temperature insulation if there is any chance the wire will get heated. Makes for long term operation. (Dave Burley) I bought my "internal" heater coil wiring from an appliance repair store. Comes with the fiber high heat insulation on it, usually in three colors - red, black, and white. It's normally used for repairing cooking oven wiring. (Mark Wendt) I don't disagree with what Al has to say very often but I think you should consider 14 gauge wire for the heater circuit. That will get you the capacity for 15 amps continuous load at 120 volts. You mentioned heat strips, plural, like there may be more than one heat strip. (Jerry Drake) Thanks for catching that. My suggestion was for 700 watts total at 120 volt. Of course if Lowell is using two heaters then 14 gauge it is! (Al Baldauski) "Strips?" As in more than one? Are you wiring them in series or in parallel? (Mark Wendt) Get the right wire from an appliance repair place, I use 14 gage. The rated wire is high temp nickel coated fiberglass, make sure you get the nickel terminals too. You will need a good crimping tool also, or at least heavy lineman pliers. The nickel coated connectors are a lot harder to crimp than the copper. Prepare yourself for sticker shock when you see the price of this stuff. Let me know how much you need, I should have some extra I can mail you. I know I have the terminals, I had to buy a whole package of I think 10 to use 4. (Tom Vagell) This is a good price on the wire. (Tom Vagell) To answer the earlier Q ....

A standard 14 AWG 60C wire has much less current capacity than a 14 AWG 200C wire, when operating at high temperatures. From a design perspective, keep as little wire as possible in the Oven itself. This excludes the impact of any fusing or CB that is inline, as you do not want the wire to the fusable link. (Dave Wilson) An occupational hazard (from my job, which includes standards and safety, amongst other things) is the selection of the right components for the right temperature in atypical conditions. Silicone wire ... good to 200C may be a smart choice ... Remember, as the wire gets hotter due to ambient conditions, you have to lower its ampacity capability (derate it). So, if you are working at close to 200C, you do need to be concerned with .. how much of the wire is being heated, to what temperature and to what current level. A 90C wire, does not mean it can run the same current, if it is at 90C, 60C or 30C. Sorry, the Code is metric. The next step ups are Glass insulated ... Mica .. You can buy short lengths from Omega, and not create a fire hazard. Of course, if you are adventurous, you can try free air with no insulators and ceramic isolators. Quite possible, but do not let little critters jump from wire to wire (ugh .... A summer job many years ago, I have to clean up such messes). (Dave Wilson)

|