Bamboo Tips - Tips Area |

|

< Home < Tips Area < Tools < Files

Does anyone know how I can clean the very fine files that I use for ferrule adjustments. The teeth get very small pieces of Nickel/Silver stuck in them. Have tried various kinds of brushes including plastic/stainless/brass. The files are about 150 teeth to the inch and getting a brush between the teeth is tough. I've been cleaning each tooth with a box cutter knife blade. It's tedious. Any ideas? (Don Anderson) You might try an old eraser. Look for one that can be used for erasing ink. Just rub it in the direction of the teeth. (Mark Wendt) What you are telling me is that you are not wiping your file on your shop apron (read that pants leg) after EACH cut. If you do not the next cut will gall the material you are filing and the file will gum up. That’s after EACH cut. (Dave Norling) I am reminded of the lessons from gunsmithing school many years ago. They taught us to never clean a file with a steel file card. If memory serves me the 6/0 file is 175 TPI and the 8/0 file is 250 TPI. I use chalk to fill the teeth and clean the file off after every stroke on my jeans. Only clean with a small brass brush. If you are loading the teeth then two things may be happening. Not keeping the file clean or pressure on the file strokes is too aggressive, or both. Some people have recommended using soap to fill the teeth but the only way to clean the file is a brass brush and water. Just find chalk much easier to use. (Jerry Young) The method that I use for cleaning my files is to soap them up before hand with ivory soap and then after dressing the ferrules I clean them with warm water and a stiff tooth brush. (Rick Taupier) The best way to clean the fine files for fitting ferrules, is to bead blast them with very fine glass beads. If you don't have a bead blasting cabinet, like I do, you may find that some of the machine shops in your area have one and will clean them for you. Possibly for free? (Dave LeClair) Was playing with the idea of cleaning fine files, posted earlier, and thought that the power fiber side of bamboo would make a great "file card". Used leftover cutoff of blanks, or a piece 1/8" wide, use squared edge and run parallel to file cut and dig out particles. Works great and fast. (Chad Wigham)

I have one of those fancy files for ferruling, but it is rather clogged with metal filings. What is the best way to clean it, and can a file be prepped before work to keep this from happening? (Jeff Schaeffer) Wear an apron when you use a file and wipe the file on the apron with each pass. Clean it with a file card. If you clean the file with each pass you will not have the build up on the file and the material you are filing will not gall. (Dave Norling) You can get a file card. It is like a wire brush made for cleaning files. There is a brush on one side, wire bristles on the other and a hook like ring in the handle to get the stubborn chips out. (Tony Spezio) I don't know if you have a glass bead blasting cabinet, but glass beading the files works good for me to keep them clean. If you rub them with chalk before you use it, it will not fill up as much. (Dave LeClair) A very easy and cheap tool to clean a file with is a section of copper pipe that has been heated to make it a bit softer. Press the end of the copper pipe to flatten it and then heat treat it to hot hot. The heat treated copper is very soft and it will not damage or dull the file. Just pull the copper across the file in line with the grain of the file. File cards will dull the file. You can thank Dennis Crockett for this idea. (Charlie Nightengale)

Anyone have suggestions as to what files I should get as a beginner rodmaker? I'm interested in ones that I can get from a local hardware store, not, say Japan Woodworker. (Joe West) You really don't need much in the way of files. A 12" and 6" mill-bastard, an 8" 2nd cut, and (possibly) a set of small files in an assortment of shapes from a local hobby store. These latter aren't really essential, but I always find dozens of incidental uses for them. Plus, they're not expensive. Beyond that, there are a couple superfine files you may want to use for ferrule honing, but these are expensive, available only as specialty items from rodmaking suppliers, and not really all that necessary (certainly, not for now). (Bill Harms) As far as files go a typical hardware store brand flat bastard will do the trick, a long thin round file will be needed for the cork grip if you buy the preformed ones. Did you get a plane yet? I bought a Stanley 12-920 at Lowes for $29.00 or so. It will need some tuning check out this site or www.bamboorodmaking.com for tips. Not difficult to tune, just time consuming. By a Hock brand blade!! the original works but needs constant sharpening, I use my as a scraper. (Pete Van Schaack) A Mill Bastard File (leveling nodes and removing glue residue) and a #3 Jewelers (Swiss) file (for filing down ferrule tabs). If you are going to lap the ferrules to fit with a file instead of strips of sandpaper a #6 Jewelers (Swiss) file comes in handy. The jewelers files are usually not available at a local hardware. A jewelry store (that has a real jeweler) will have plenty of used ones as will a machine supply. (Marty DeSapio)

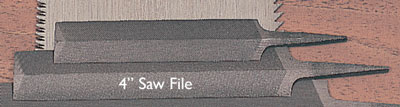

This tool is new to me and works so well I thought I'd share it. Japan Woodworker sells a Feather Edge File for sharpening Japanese style saws.

I use it as the ultimate 'fine tooth' saw for trimming delicate tips to length. Works great for filing splinters off corners to insert in ferrules or reel seats as well. Four inch file for ten bucks. Warning for those who enjoy fine tools, this place can be dangerous to your wallet. (Ed Berg)

What is the difference between a Grobet #6 pillar, and a Grobet #6 double cut hand file. I'm thinking about getting one for ferrule lapping. (Floyd Burkett) As for the files, I don't know the difference. I hope someone will know. And I wish you would share where you have located the #6 double cut hand file. (Harry Boyd) I think I just remembered the difference between the two types of files. If I remember correctly, a pilar file has smooth sides (no cutting teeth), and the other type may have teeth on the side. I know the Grobet pilar files I have are smooth on the sides. (Mark Wendt) Really? Could you explain further? what do you use it for? (Timothy Troester) Mark needs no help, I'm sure, but if you pull out your trusty Nicholson ("A file for every purpose") and it's the usual flat deal, say 10 inches long, 3/4 of an inch wide, and an eighth thick, roughly, look at$ the four sides of the "blade." You see the diagonal grooves on both flat faces that do the cutting, and if you turn the blade on edge, you see the same parallel grooves that run across both edges. A "pillar" file has no grooves on the edges, only on the flat faces. There you have it, mister bear. Let me know if you need a picture of one, which would, for sure, be worth a lot of my babbling. (Steve Yasgur) Thanks! I got it. Like you I call the edge of a file an edge not a side, I call the sides or flats sides or flats. So when Mark said sides of the file were smooth I had a different picture in my head. I have already made my once in a lifetime trip for left handed rail benders and Mark being military and all I didn't want to have to make that trip the second time in this life time. Caution! (Timothy Troester)

Has anyone out there found a source for the Grobet Swiss files at a competitive price? I don't really want to pay ~$60 per file if there is a better source out there. (Scott Bahn) I don't recall offhand what size we use for ferrules. But what about here? (Timothy Troester) Since I also piddle around with making acoustic instruments (dulcimers and guitars, etc), also, I have a box of nut files The "nut" is the ivory, bone or plastic string holder at the top of the fingerboard. these are aka Swiss Pattern files. They are made by Hiroshima Files Japan and called "files.of.minute.use" Swiss Pattern Files. I have no idea where I bought them and a quick search of the internet and my Order Confirmation file all the way back to 2006 produced nothing. Likely, I got them from a supplier to Luthiers, but not Stew-Mac. These were very reasonable. I can guarantee I didn't pay $20/ for these, as I have 10 in this box. You can also check Stewart MacDonald who sell these nut files and while they are high priced in general, I don't recall their nut files are that much. But they won't be cheap. (Dave Burley) Try these guys, Gesswein jewelry. Got rope knurl from them as well. (Don Anderson) There are a few differences between what has been recommended to you and what Swiss Pillar files are. Pillar files are different that equaling files. Also, very important, a 6 cut or 8 cut is probably what you will use the most, with the 8 cut being the one I use most. I know Bailey Woods carries the Grobet files, and may have the 8 cut as well. As far as price, I don't know what they cost at present. Seems I paid about 35 dollars for mine, a number of years ago. I am trying to finish up editing some film I made for finishing up on the micro ferrules. I use the 8 cut Grobet pillar file for the final fitting. (Chris Raine) Here's a question about Grobet files - when they eventually get all gunked up with nickel silver, how do you clean them? Just with the usual file card, or is there something more kind of Swiss, and more effective? I have done all the chalk and soap stuff, but eventually they gunk up anyway. (Peter McKean) I take mine to a powder coating company, they have equipment to do mild blasting with fine glass beads, as well as sandblasting, and a type of silica blasting. The glass bead blasting works great, the files come out like brand new. I've been told not to use sand blasting, it may damage the files. The guys in the powder coating shop told me that's hard to believe since files are such hard steel, but they won't try it either... It only takes a few minutes, and they won't charge me for it, so I buy them beer. I still soap up the files before use, but you're right - it doesn't take them long to gunk up anyway. (Tom Vagell) The gunk is called "pinnings" and it must be removed. But that is easily done. Anything softer than the file will do so. I use a brass cartridge case crimped flat at the mouth, because it removes the pinnings over a large surface, and quickly. I will try to finish editing my YouTube videos on ferrule making and show you how I do it. I think it is important to use the right file for this, and I think the Grobet Swiss Pattern in an 8 cut, Pillar file is the easiest way to do this. (Chris Raine) Great question. I answered it in my video, if I could figure out how to you tube it. What you need is anything softer than the file to remove the "pinnings". I use a cartridge case made of brass crimped at the mouth. Rub it along the teeth, and it will remove the pinnings. (Chris Raine) It's a tough slog, but I use bamboo cutoffs, the ones that have been sorta rough beveled to the 60º shape, and I work the surface of the file with the enamel side on the end of the stick. Doesn't hurt the teeth like a steel file card would. (Mark Wendt) I want to put this out to the list, for lurkers, for the grits boys, and for the contributors. I have taken a lot of time dialing in the making of ferrules. Classic Sporting Enterprises (Bailey and Steve) are the 400 pound gorillas on your front lawn. They deserve this status. You buy their ferrules, and have a great starting point. Pillar files. That is what is used for bringing male ferrules into dimension. Pillar files are "safe" on both edges. Not so with equaling files. This is important. And significant. Bailey sells Pillar files. If you want to fit your ferrules correctly, this is where you start. Or, you can ask Bailey to fit your ferrules for you, at a reasonable cost. He will use the pillar file Again, I will have a video on YouTube addressing this issue. I'll let you know. But it is a Pillar file that you need, and an 8 cut. (Chris Raine)

What is the best way to clean out the shavings from a Grobet file? (Walt Hammerick) I haven't tried it on a Grobet file specifically, but the best trick I've found for cleaning fine files is to run a thin piece of aluminum along the teeth. An 1/8" thick by 1/2" wide scrap of aluminum sheet is about perfect. Just rub the piece back and forth parallel to the teeth. After a minute it will cut grooves into the piece of aluminum and clean the swarf out of the file. (Mark Shamburg) First shoot your .3030, take the empty cartridge and mash the end down and use this mashed end to winkle out the bits. And next time use a bar of soap to rub on the file to make it easier. (Dave Burley)

I love Epon, but sometimes my schedule doesn't allow my to remove the stuff from the blank at the most optimum time. I generally use files and a draw filing technique to remove the pesky stuff. Last night I was having trouble cleaning the gummed up files with a wire brush. Until I tried something new. I doused the files in a bath of acetone and then cleaned with a wire brush --- worked GREAT .... (David Van Burgel)

I am tired of lapping ferrules with sand paper. Where have you guys found a good (aka - economical) place for Grobet files? If you were only going to get one, which would you get? #4 or #6? (Matt Fuller) I have a #6 and a #8. If I had to have only one I guess would go for the #8. (Peter McKean) Jeff Wagner has them in three cuts - #4, #6, and #8. I got all three. You can get by with having a #6 and a #8, but the #4 is handy to have around when you have to "hog" a couple of half-thousandths off. (Mark Wendt) #6 $35.63 + shipping. Not cheap anywhere. (Larry Swearingen) Check these out. Regular Pillar files for 4 to 6, escapement files for #8. (Gary Marshall) Good work Gary. Proving once again that it pays to shop around! Myself, I already got a 6 at the local Restore for 50 cents. Guess nobody else wanted it. (Don Ginter) How about the "sanding file" here? You could put #400 wet/dry on to start and go as fine as you want. I haven't tried it--yet--but I'm going to try to pick one up at the next woodworking show. Usual disclaimers. (Neil Savage) That looks like not much more than a hardwood block with sandpaper on it. I think I got the idea from somewhere in the rodmakers tips section years ago. (Joe Hudock) Seems to me back about 1946 when I made my first model airplane the kits came with a piece of wood (pine?) that you glued a piece of sandpaper to. This isn't glued on but the mechanism tightens the sandpaper (at least that's how I think it works.) I'm going to take a look at the Detroit Woodworking Show in December. I think I could use it in the shop, and for $6.00 what the heck. (Neil Savage) Or you could just go to HF and buy a cheap set of jewelers files for about a couple of bucks. (Mike Shay) But those needle files aren't anywhere near as wide, nor as finely cut as the Grobets. The Grobets I got from Jeff are 1/2" wide, which makes it much easier to keep from tapering the male ferrule barrel, and the fine finish I get from them usually only requires a touch up with 1000 grit, then 2000 grit, then finally with steel wool to really make the barrel shine. I tried the jewelers file route before I got the Grobets, and I gotta say, the Grobets are far and away much nicer, easier to use and give a much better finish. They're called lapping files for good reason. The needle files have a much coarser cut. (Mark Wendt) That's probably all quite true but I essentially do all that with these little files and it's really no problem. If one wishes to spend that kind of money for a file, then by all means knock yer self out! It really isn't a problem keeping from tapering the slide? In fact, it might be easier not to taper the slide with a smaller file. There is no chance I'll over file an area if the file isn't on it. And hey...they call them jewelers files for good reason. Don't know why exactly, but I'm sure it's good. (Mike Shay) I hear ya. They aren't cheap, but then again, quality tooling usually isn't. Like I mentioned earlier, I used the needle files before I got the Grobets. If you ever get a chance to use the Grobets, you really won't want to go back to using needle files. (Mark Wendt) I broke down and bought a # 8 Grobet file about two months ago. I finally got to use it today. All I can say is WOW. I had been using my block setup with fine sand paper. ( (See Power Fibers Issue 7 Apr 02 Lapping Ferrules) The file did the job in half the time, a little polishing with 4/0 steel wool and it was finished.. (Tony Spezio) Ayup. Good stuff, idn't it? I demo'd the use of the Grobet files a couple of years ago at the SRG. They really are easy to use, and they do work great! (Mark Wendt) I used some chalk to coat the file before using it but still noticed some lines on the file teeth after it was used. What is the proper way to preserve the file? I used a Mini Brass wire brush to clean the file teeth after it was used. Seems I remember reading that the file should be coated with Chalk or Soap before use. Then something about a brass cartridge to clean the file. What procedure do you use? The chalk and brass brush works well on my larger files. On my coarser files I use a File Card. (Tony Spezio) I use a sharpened piece of cane to clean these files, brushes are not usually fine enough. Sharpen the end of the cane (a normal 1/4" spline piece) to a chisel point and push this along the line of the file teeth. the file teeth cut into the cane which then cleans the troughs. Re-sharpen as required. I find that for #4 and #6 it is not essential to coat the files before use; the cane cleans them easily but the #8 is a different matter. The most effective treatment I have found for the fine files is a light coat of Trefolex, a soapy oily compound used for tapping and reaming. (Gary Marshall) I have some tapping oil; I guess that will work. I have plenty of bamboo scraps that I can sharpen. I will have to try it on the next set of ferrules. It will be a while before I will get to it. (Tony Spezio) I bought my #8 Grobet from Bailey Wood at CSE and love it. In his catalog description he says the following "before using a file, first charge the filing surfaces with ordinary bar Ivory soap or its equivalent. When the file needs to be cleaned, brush it out under hot, running tap water using one of our stainless steel bristle brushes. Then, dry the file thoroughly. Recharge it with soap and it is ready for reuse. Stubborn metal particles can be dislodged by using a squared-off piece of brass rod to push them out 'with the grain' of the file teeth." The brushes are listed in his catalog for under $3.00, and the comments in the catalog state "Use to clean our Grobet Swiss Ferruling Files. Excellent for dislodging the fine metal particles that become imbedded between the teeth. Ordinary file cards are too coarse." I spoke with him at the Catskill gathering, and he indicated a spent shell casing could be used to do the job as well, something I guess you hunter guys might understand better than me. FWIW, and unfortunately, no financial interest...... (Jim Rowley) I really appreciate everyone's input on the Grobet files. It looks as though they are $45-$50 no matter where you get them from. I always thought they were about $25-$35. I think for the time being I am going to stick with sand paper or what I usually use is a fingernail file or buffing pad that has various grits. (Matt Fuller) Chalk is good, but you need to have the right kind. I believe it's called "railroad" chalk, and you can get it at your local welding supply shop. Or, you can do like Frank does, and use a little cutting fluid/oil. Since the teeth on the lapping files are so fine, it can be a real bugger to remove the occasional pin. For the real stubborn pins, I use a HSS scriber to pick the pin out. Somebody a while back, one of our European friends I think, posted that he used a piece of cane to clean out the teeth. I tried that and it works pretty good. Don't use a steel brush or file card on these little guys. The steel will wear the teeth prematurely. If you are going to use any brush at all, a brass fibered brush will work. I've never tried using the soap, so I can't comment on that. When not in use, I always put the file back in the anti-corrosion paper tube that came on the file when I bought them from Jeff Wagner. Dunno if he's the one that puts those on there, or if they come that way from Grobet. Oh, and since a lot of us have lathes and use these files while the ferrule is mounted somehow in the lathe, please outfit all your files with handles. If you've never had the tang of a file go into your hand or arm after the file got caught on something turning, you really don't know how painful that is, or how bad the chance of the wound getting infected is due to the metal chips, cutting oils and other stuff. (Mark Wendt) I actually squashed the neck of a Thutty-thutty (.30-30) case in the vise, and massage the grain of the Grobet with the thin edge of the flattened neck. I haven't found a brush that will work as well. Can't abide the thought of using an annealed, outside-neck-turned, OAL-trimmed .270 case . . . (Steve Yasgur) I bought a #4 & #6 from Wagner. Coat the files with plain old bar soap, like Ivory or whatever. Use the #4 to do most of the cutting, follow it with the #6 for a second or two, then some 2000 grit paper & 0000 steel wool. Only takes a few minutes to do a set of ferrules # they fit a LOT better than when I didn't have the files. The files clean up in a flash under some hot running water, scrubbing with a The files are pricey, but worth it for the quality precision work they do. (Paul Julius) I will also vote in favor of the Grobet files. They work fine. I don't know if I have the #6 or #8. Is there a way to tell? I would like to get the other. (Larry Tucker) The size number is stamped on the tang. (Peter McKean) Thanks, removed handle last night and found it. Was expecting marking to be closer to cutting area. (Larry Tucker) I started out using a variety of finishing papers up to 2000 many years ago, then tried some other type of files with diamond surfaces for fitting the male to female ferrules. Once you acquire a Grobet file and use a little cutting fluid you will never fit files any other way. Just my experience and opinion - the investment is worth your time and frustration. (Frank Paul) That is quite true. And if you take care of the Grobet by soaping the faces and by cleaning out the pillings from time to time, they will last you pretty well forever if all you are cutting is nickel silver and brass. You get what you pay for! (Peter McKean) I take it you would agree that the correct way of using the Grobets is to pass from the end of the slide back toward the welt, rather than vice versa? (Don't ask why I ask!) (Steve Yasgur) One must insure that one gets an almost uniform form taper from the end of the male ferrule to the stop (I assume you mean by this the welt) so that the male ferrule seats into the female ferrule smoothly and with some increasing tightness. Just my opinion. (Frank Paul) Actually, you'll get a much better fit over the length of the male barrel if the male barrel has no taper. The male ferrule will seat much better with no taper. The ferrule fit depends on friction, and when the friction is spread out evenly over the length of the male barrel, that fit will last longer and be better for the ferrule longevity. With a tapered male barrel, you're creating pressure points where the fit is tighter at points than other. For precision fits, that's a no-no. (Mark Wendt)

I was busy removing the glue from a dryed blank and dropped my file. I picked it up and continued the task but this time as I filed the blank it squeaked. I thought it was funny at first but now it's driving me crazy. I can't keep building rods in these circumstances. will someone please share with me the procedure for calibrating a file.?! (Timothy Troester) Drop it again and make sure that it lands on the other side. (Dave Cooper) You don't want to calibrate it. You need to tune it! (Peter McKean)

|

Christmas Missives - Chat Room - Photo Galleries - Line Conversions - The Journey - Extreme Rodmaking - Rodmaker's Pictures - Donate - Store