Bamboo Tips - Tips Area |

|

< Home < Tips Area < Hardware < Ferrules < Fitting < Fine Tuning

I need some insight into what might be happening. I'm hand fitting a set of ferrules and am working with 1200 grit paper and 0000 steel wool. As the fitting is progressing all of a sudden it feels like the bottom falls out of the ferrule and I have lost the fit. I now have a ferrule that fits up to a point and then just slops. I mic the male and it appears to be consistent along the length (no signs of a waver in the dimension). Not being able to check the female dimension the total length of the fit I'm at a loss. I had this happen another time and just got another ferrule. Would like to be able to give feedback to the person making the ferrule or have an idea myself what is happening. (Jim Tefft) Is the male ferrule being inserted straight in? If it is, it sounds like the female may be tapering to a larger diameter as it gets to the bottom, or it may have been reamed out of round the further you get into the barrel. (Mark Wendt) Sounds like you have some poorly made ferrules. I found that same thing once on a set of ferrules made by a friend of mine (not currently on this list). I finally figured out that the money I saved bluing ferrules that cost a few dollars less per set would have been better spent on quality products. I now use only ferrules by CSE (Bailey Wood), REC, and Tony Larson. I really have no favorites among those, but have chosen to build all my rods with the same style of ferrules and will only buy from one maker in the future. (Harry Boyd) I like those three as well. The range of sizes from CSE is really nice. I like to use a truncated on the butt of 3-piece rods with a full size on the tip. I used an REC Uniferrule for the first time recently and it fit easily and looks great on the rod. I'm looking forward to using the step-downs I got from Tony. (Jerry Madigan)

On my latest rod, I got lazy and didn't mic the male ferrules often enough while lapping them, and ended up with a sloppy fit. I was checking the fit regularly, but didn't realize the tip of the male ferrule was causing it to fit tight rather than the shoulder of the ferrule. One of the tips makes the nice "pop" sound when you pull them apart but has a little click, almost a hinging effect when the rod is flexed, and the other is just plain sloppy with minimal "pop". My question is: are these ferrules ruined, or can they be salvaged. Can a guy rub them with a little beeswax or other such "lubricant" (the kind people said I should use on ferrules as a kid) or do they need to be removed from the rod and thrown away? (Wade Turner) There are 2 things I know of besides deforming the male that may make the rod usable. One is to use hard candle wax. It does not attract grime like beeswax. The other is to smear a little super glue on a clean male end and when it is dry, sand it lightly to fit. This will last a surprising length of time. (Timothy Troester) You can try this, it has worked for me on some old rods with loose ferrules. Wrap one layer of masking tape around the female ferrule, make the ends of the tape flush. Using a three jaw chuck, tighten it on the ferrule just a bit, loosen and turn the ferrule 1/3 turn and tighten again. Be sure that the welt of the ferrule is back behind the inner part of the jaws as not to damage the welt. Tighten just a slight bit at a time and check the fit each time. Hope that will work for you. I fit my ferrules before gluing them on. (Tony Spezio) Another trick that I've used is to use a couple pieces of lead as a hammer and anvil. The lead is soft and will not mar the nickel silver. Rest the female ferrule on one piece of lead and use the other to tap on the ferrule as you rotate it. Check the fit frequently and gradually reduce the size of the female until you get the fit you want on the smaller of the two males, then fit the remaining male. (Robert Kope) There are a lot of tricks like wax or squeezing the female, etc. But, these don't really work all that well. The best way to take care of this is to either replace the ferrules and start over, or the males can be nickel plated and refitted to the female. I just did two sets this weekend for a couple of guys. If you decide you would like to get them built up with nickel plate and refitted, just email me and I will see what I can do to fix this problem for you. (Dave LeClair)

I have a 2 piece Wojnicki rod; one tip fits perfectly but the other tip is very tight and I can only seat the ferrule about 3/4 of up the male ferrule. Obviously the problem is with the male ferrule on the tip since the other tip fits great, right? I have cleaned both the male and female ferrules thoroughly. So what's the next step? I'm open to any suggestions. (Bob Murphy) My first suggestion would be to contact the maker and see if he can adjust the fit for you. If that won't work, I have a minor treatise on ferrule refitting I would be happy to share with you. (Harry Boyd) I am sure many of us would like to see this. Is it on the tip's site? If not, it might be nice to have it there. (Rich Jezioro) Not sure if I have posted this to the List before, but most of the information was, I'm sure, gleaned from generous friends here and other places. Sorry if I fail to credit anyone (John Gierach) I should. Below is what I send out with each new rod I ship. I include some 1000g sandpaper, some Q-tips, and some 4/0 steel wool in a little "Rod Care Kit," and these instructions. Boyd Rod Company Adjusting Ferrule Fits A proper fit on ferrules is essential to the well-being of your rod. The male ferrule should seat all the way to its shoulder. If it doesn't fit all the way you run a serious risk of damaging the rod. My ferrules fit fairly snug, and require a good steady push to seat fully. Always keep your hands close together while seating the ferrules, and keep your hands as far apart as possible when unseating them. Remember the mantra "Hands together, rod together. Hands apart, rod apart." No one seems to understand why ferrules "grow" a little after the rod is a few months old, but it is not unusual. I'm glad to give a little instruction on re-fitting the ferrules. I'll be just as happy to re-work them myself if you send me the rod. The choice is yours. To re-size the ferrules, start by cleaning the male slide and the interior of the female with some kitchen cleaner like Formula 409 or Fantastik. If that doesn't do the trick, start with some Scotch tape. Tape off the shoulder of the male ferrule and the ferrule wrap. Cover the Scotch tape with a wrap or two of masking tape. If you don't still have what I sent you when your rod was delivered, get some 1000 g sandpaper from the auto section of Walmart, and some 4/0 steel wool. I always send along plenty to make the ferrules fit perfectly again. First, before you start, be sure _you_ try to seat the ferrules yourself. Most folks are scared to put enough pressure on them, but remember "hands together, rod together - hands apart, rod apart." A good nickel silver ferrule takes more pressure to seat than a graphite ferrule. It should fit with about the same pressure it takes to fasten your belt a notch or two tighter than is really comfortable. If the ferrules don't fit on the first attempt, try just a little steel wool polishing. In fact, I carry steel wool in my reel bag and polish male ferrules almost every time I put the rod together. Make a "rope" of steel wool by pulling off a little steel wool from a pad. Wrap the rope around the male end of the ferrule and give it 4-8 twists. Wipe the male off on a paper towel (or your t-shirt) and set it aside. Stuff the rope of steel wool down in the female ferrule and give it a few twists. Then clean out the female with a Q-tip, and give the ferrule another try. If a few tries with the steel wool doesn't do the trick, it's time to go to the sandpaper. Wrap a small piece (2.5" by 3/4" to 1") of the 1000g sandpaper around the male ferrule. Hold both ends of the paper in one hand and keep things just snug, not tight. With the other hand, give the rod 2-4 turns. Remember, you can always take off a little more, but it's tough to put it back on. You should see a very fine scratch pattern on the ferrule. Polish the scratches away with 8-10 turns of the steel wool. Wipe on the paper towel again, and test. This may well do the trick. If it doesn't, be patient. Make a few more turns with the 1000 grit, and the steel wool, and try it again. Remember, never go more than half a dozen turns with the sandpaper/steel wool between fitting attempts. The difference between a good fit and a loose fit is only .0001"!!! Of course with 1000g sandpaper, you are only removing a teeny-tiny fraction of a thousandth per turn. This all sounds more scary and difficult than it really is. I can fit all the ferrules on a 3pc 2 tip rod in half an hour. It isn't hard to do. Once you've done this the first time, it won't seem so scary. Go slow, test often, and you will do fine. But my offer to do this for you always holds. It only takes me minutes to do this, and if you don't want to fool with it I'll get the rod back to you in less than a week. (Harry Boyd) Three strokes with fine steel wool. Try the fit, and repeat as necessary. One gets better with practice, but I typically never do remove enough being very conservative about reducing male ferrules. However... be sure that clean both the male & female ferrules thoroughly first, before even contemplating resorting to more drastic measures. I use conventional silver polish, with Q-tips for the female ferrule. (David Zincavage) The first thing that I would do would be to carefully mic the ferrule that fits in several places and then do the same to the tight one. That way you can determine what the problem is. IE, a bulge, out of round, bent or just oversized. If it is a nickel silver ferrule you can probably remove a bulge or take down some extra material. However, if it is a plated ferrule you will very likely expose some of the metal that the ferrule is made of. I have made out of round and bent ferrules work, but I have never been satisfied with the results. They never have that "pop" when pulled apart. (Don Sargent)

Some time ago, I think I read of a technique of increasing the diameter of a male ferrule by internal compression. Any one know I have a misfit male that needs a fraction more diameter, and I am disinclined to squeeze it with a three jaw chuck. Can it be done and if so what method should I use. Or should I just breakdown and buy a new set??? (Ralph Moon) Although I've never tried it, someone said a long time ago to fill the male with salt and tamp it with mallet and a rod of proper size. (Don Schneider) I'm confused (as usual) if you want to increase the ID of the male, how would squeezing in a 3 jaw help? (Neil Savage) It raises little ridges and a four jaw chuck is even better! (Robin Haywood) I want to increase the OD not the ID. Squeezing it in a three jaw chuck will distort it out of round into a more triangular shape. It does work, but I am raunching enough that this kind of distortion does not sit well with me. (Ralph Moon) One quick and dirty way is to carefully coat the male with Zap a Gap or other cyanoacrylate. Let it cure and lap the ferrule as usual. This is practically invisible and lasts quite a long time. (Doug Easton) Making it out of round, I saw that posted one time a while back. I think Ralph meant the female. (Tony Spezio) How loose is it? Is it clicking? Are the sections separating while casting? I have a light weight spinning rod that has a loose fitting set of ferrules. They don't click or separate while casting, but they turn! Not a lot, but every once in a while, I have to straighten the sections back. They slide together/apart with ease, verrry easy!! But, they have never came apart!!! I'm waiting to see how long this will go on till I need to do something with them. Till then..... (David Dziadosz) I haven't tried it but... if you fill the ferrule with fine sand or salt then using a short piece of cutoff rod section that just fits into the ferrule tap it gently with a small hammer you should be able to enlarge the ferrule slightly. Hit it real hard and you'll probably have a Nunley moment :>} Probably worth a try before you buy another ferrule. Another thought is to ship it to Dave LeClair to be plated but probably not worth the time and expense over buying new. (Dennis Higham) Now you have me concerned. I certainly don't want a Nunley moment, but knowing me, I think I may expect one. How you doing? (Ralph Moon) Be careful to do it straight as an arrow else you'll knock the ferrule out of line. (Tony Young) You could try this: if you have a set of brass lapping tools they have a tapered pin screwed in them. The ones I have unscrew from the aluminum shaft. Select the size that just fits inside the male ferrule, insert the brass tool & screw in the pin. You could cut the lapping tool in half so it just expands at the end & then expand the ferrule in several places along the length. (Ron Larsen)

For those interested. Filling the male and with salt (sand) and pounding a drill bit in does not work for me. I ended up squeezing it in a three jaw chuck. Not visible but does tighten it up enough. (Ralph Moon)

It would seem to me that I have screwed up but let me know if there is a way I can fix this. I install ferrules by hand as described in the tutorial on the tips page by Denver Dave. The first rod turned out great and I had no problems except that the ferrule didn’t seat completely, maybe 1/16” left. I figured that was good enough for the first rod and would leave room for years of wear and tear. I installed the ferrules on my next blank using the same method. The first male ferrule I sanded carefully getting ever closer to the final size. I somehow over sanded and it bottomed out with little pressure. It made a nice pop when removing but it just slid on way to easy before bottoming out. I thought what the hell, I am only making a 2/1 so I’ll use the other male that came in the pack. I followed the same steps except this time I was going to stop while leaving a little room for play. I sanded very carefully. After the male started sliding in the female, when I would pull the sections apart, no pop. I thought, well there is quite a bit of the slide left so maybe I’ll get that pop once properly fitted. I worked very carefully checking my progress often. Still no pop but getting a nice tight fit. When I got down to where I had just a little play I stopped. Great fit to me but no pop. I shook the blank repeatedly, mimicking casting, no clicking, no tip flying off into the yard. When I separated the section, no pop. What gives? Why no pop? (Greg Reeves) It could be the air is being pushed out of the bottom of the ferrule. (Gary Nicholson) I know exactly what you mean. I had exactly the same problem and just figured it out. Dave's tutorial is great and that is how I do my ferrules. However, he is able to keep a good even pressure on the sand paper over the entire length of the ferrule, which I apparently cannot. As a result, when I am done the diameter of the male is not exactly the same all along it's length and it often had a small high at the top of the male, so the female won't slide on that last 1/32 of an inch. It may be tight enough at some point along its length so that the fit with the female is OK, but it does not create a seal over a broad enough area to hold the slight vacuum that you create when you separate the ferrules, which is what makes them pop. For me the answer is simple, use the sandpaper over a flat piece of wood (I use a piece of a paint stirring stick). Since it makes a nice even diameter all along the length of the male ferrule, after you are done it will slide all the way into the female and will make a very nice pop. Hope it works for you. (Jack Follweiler) Exactly !! I use foam salon boards rather than wet or dry sand paper. (Doug Easton)

I recently finished lapping a ferrule. When I assemble the rod and seat the sections sometimes they slowly separate as the air pressure pushes it back out. So, have I gone too far (or not yet far enough). (Dan McConnell) Does the male ferrule come out of the female ferrule or are you saying the rod blank section slides back out of the ferrule? (Ren Monllor) If you can seat the ferrule on the rod full depth, you've gone far enough. Now, when you glue the ferrule on the rod, you need some way to either let the air escape or hold the ferrule in position until the glue dries. Some people scribe a channel in the bamboo under the ferrule to let the air out. I just hold the glued up ferrule against the edge of my work bench until it doesn't move anymore, and then wrap the tabs with heavy twine. (Ron Larsen) It looks as if I wasn't absolutely clear. It is metal to metal, male to female that is sliding apart. (Dan McConnell) You went too far…. (Ren Monllor)

I recently ordered a set of 12/64th's Uniferrules from REC to replace the ferrules on the first rod I made (lapped them too much the first time - I hate fitting ferrules). I glued (with Pliobond) the new ferrules to the rod a few weeks ago and then last night finally got around to the task of fitting them. Much to my surprise they were already perfectly fit. Beautiful smooth putting the rod together, and a perfect pop taking it apart. Is REC prefitting their ferrules now, or are the ones I received some kind of anomaly? (Aaron Gaffney) Did you get Titanium? They are generally prefitted because you can't lap them down in a single generation. If they're NS, I've never gotten them prefitted before. (Mike St. Clair) I used one set, they didn't seem to require any less work than any others. (Henry Mitchell) I use the REC Uniferrules for nearly all the rods I build. For the past couple years they have required very little fitting. I round the shoulder slightly with a file and finish the fitting with a few strokes of 1000 grit sandpaper. It takes about 5 minutes to fit a pair of males. My positive experience covers probably 25 sets of ferrules. (Bill Lamberson) I think that it's an anomaly. You just won the lottery, sort of. I am currently fitting a set of 12/64th's Uniferrules from REC and trust me, they are not prefit. Of course, I've had these around the shop for some time so this could be something new. Still, I think if this was the case they would be advertising it as the greatest thing since sliced bamboo. (Hal Manas) I think you got lucky. I have used a lot of Uniferrules in the past but your very circumstance is one of the primary reasons I stopped using them. Consistency was the issue. I got a couple where the male was too loose in the female out of the bag and I have received them where the female was wallered out in the bottom. REC has usually been prompt and accurate I do not have any beef with them. I just went to other ferrules. (Timothy Troester)

Has anyone ever tried freezing a female ferrule in nitrogen or CO2 to shrink the ID? I have a female ferrule that I'd like to tighten up, and a machinist friend suggested dipping in liquid nitrogen or rolling it along a block of dry ice. He thought the ferrule would re-expand as it warmed, but to a slightly smaller diameter. All I need is probably half a thousandth, since the ferrule fits, but is simply not snug. He also didn't think it would affect the metallurgy, or make it brittle. Thoughts, anyone? (Greg Kuntz) At the Colorado Rodmakers Reunion this July Alan Kube and demonstrated electroplating a male ferrule while still fitted to the blank in order to slightly increase its diameter. The results were amazingly good and increased it enough in a short time to where it needed to be lapped just like a new ferrule. You might want to look into that process. (Ralph Tuttle)

I have been using Uniferrules for the past 10 or so rods and have been pleased with the ease of fitting male to female. The last rod I completed I found that almost no fitting was necessary, but the fit seemed good. My latest rod I am somewhat concerned with. One male required a small amount of sanding and polishing to fit properly (but very little). The second male slipped right into the female on the first try without any alteration. As I released the pressure used to push the sections together the ferrules separated about a quarter inch on their own, I am assuming from compressed air in the female (sort of like when you hold your finger over the outlet of a syringe and press on the plunger). If I twist the sections slightly they remain fully seated, and when I pull them apart I get a nice "pop". I tried some casting motions which did not seem to want to separate the ferrule sections, but I am concerned that this fit is too loose. Any suggestions on how to judge this, or how to fix it? (Ray Wright) There have been several suggestions on how to fix a too loose problem but if they are too loose out of the bag I would send them back. I had difficulties several times where I found the female was wallered out, larger at the bottom of the hole than at the opening. REC said it was impossible but I had it in my hand. They exchanged them. There was no comment on what they found. I just started using other ferrules. Overall I have found REC very helpful and compliant to my requests, though. I suppose when you make lots of ferrules things can happen for them just like they can happen to us. (Timothy Troester)

I am not sure who suggested this, but I put on a very quick and thin coat of super glue liquid on the male. I left the male dry very well, cleaned out the female with alcohol, and then rubbed the male ferrule with 4/0 steel wool - just a little. I now have a rod with a tight fitting male/female ferrule. I will be anxious to see how this holds up with more use. Just my experience and thanks to whomever suggested this approach. (Frank Paul)

Last year I refitted an old HI rod (brother-in-law's) with new NS ferrules. Originally it had a bad fitting set of what I believe were incredibly cheap nickel plated brass ferrules. Scored, out of round, stuck every single time, etc. Fishing it for smallmouth, nothing fancy. When I turned the male on the new set down I thought I did a good job, got a nice 'pop' pulling them apart. But now, after fishing for maybe the tenth time with this rod, they're definitely loose. Not by much, but clicking and you can twist the rod out of alignment too easily. Clearly, I took a smidgen too much off fitting the male, although I didn't think so at the time. In desperation (my middle friggin name), I dipped the male in Tru Oil a couple times last week, let it dry, and, believe it or not, it did help, but the coating wore off, naturally, and then you have to swab the crap out of the female after just to be safe and keep things from clogging up for the next round. I could keep doing this (until my brother-in-law asks for his rod back!), but was wondering if there might be some other quick-fix other than springing for another set of 14 ferrules and doing it right this next time? Stupid question of the week, right? My specialty! I can hear you guys already...! (Bob Brockett) Not to worry. put the female in your 3 jaw chuck on your lathe and gently tighten the chuck. Remove, rotate a little and repeat. Then try for fit. Remember, gently! (John Dotson) I've used this same method several times when I've taken too much off the male and it works great. I apply several wraps of masking tape to the female before I put chuck it up to keep from leaving marks. Good Luck! (Tom Key) What I did is what you did with the varnish but I used super glue. It will last longer. Next I coated the male with dripless candle wax and it holds better. These are both temporary you can ask someone who has done it about making the male slightly out of round with a 3 jawed chuck. Someone has plated a male slide. Maybe someone will come up, someday, with a permanent more pleasant solution. (Timothy Troester) Having noted the suggestions that you squeeze it in your chuck, let me add that if you have a set of collets, the appropriate collet will do a much tidier job of squeezing the female than the jaws of a chuck. However, they will do the job if no collet available. (Peter McKean) A pair of 'vise-grips' near a ferrule is scary, but here's my method. (a vise works too). Take a snap-type clothes pin, adjust the vise grips to apply some slight pressure, and starting near the middle of the female, just rotate the ferrule as the pressure is applied. Then move up until you get the desired fit. (Vince Brannick) I have done it by squeezing the male slide in the 3 jaw chuck. Wrap the ferrule in about 3 layers of masking tape first and then squeeze it firmly in the chuck noting the relative position of the slide in the chuck. Don't squeeze too hard at first. Take off the tape, clean off any stickiness left over from the tape and test fit. Chances are there will be no difference because you actually have to squeeze harder than you would think to make a difference, but it is worth building up to that point, so wrap in tape again and place back in the chuck so you squeeze over the same 3 spots. Squeeze that little bit harder. Repeat until it works. You may have to take off a tiny bit again with 2000 grit or 0000 steel wool to get a good final fit It works perfectly well but is never going to feel as smooth as a properly fitted ferrule does. (Steve Dugmore) Another option is to contact Dave LeClair. I know he's done some replating in the past. I'm sure this would be the best solution in the long run. (Todd Talsma) The plating option IS probably the best IF the male spigot has NO taper. (Al Baldauski) Thanks everyone for the help! Very interesting. Proves again the old adage about there being countless ways to skin a cat (how crazy hungry was the first person to say that??). I'll decide which way to go tonight, probably. Go for the quick-fix, but have to say this replating has me very interested, since this may be the first time this has happened to me, but sure won't be the last and the best way of doing something is what you need to know. See what I can look up on that when I get the chance here. Thanks again, guys! (Bob Brockett) Parts hanging in the Chromic Acid bath may build-up more on the sides toward the anode(s). Am not familiar with Dave's process, but he may have the solution (no pun intended) to this potential problem. Dealing with only 'tenths', there may not be a problem, and if there is, lapping (no pun here either) may obviate it. (Vince Brannick) I believe Dave LeClair uses nickel plating which has great "throwing power" i.e. it covers uniformly. I don't know if nickel can be lapped easily. (Al Baldauski) Must admit to not knowing enough about nickel or chrome plating on nickel-silver. Have generally assumed that plated nickel-silver ferrules were chromed. I do know that some nonferrous base metals, in order to be chrome plated or even nickel plated need to be copper plated first. Also there is hard nickel as well as soft(er?) nickel plating. And there's 'brush' plating too. Maybe Dave will chip in with some enlightenment. (Vince Brannick) Oh, forgot to mention, nickel plating (I believe) needs nickel anodes to deposit a plate, whereas Chromium electrons deposit wholly from the solution. No? Guess I better keep squeezing the clothespin? (Vince Brannick) Isn't there a way to expand the male ferrule? I seem to remember someone saying about removing the male ferrule from the blank, filling it with salt and hammering the salt - which causes the male slide to expand infinitesimally, reattach and refit Of course I might be wrong I also seem to remember someone saying you could just hammer the flat end of the male ferrule with a hammer (lightly) and this forces the male to compress/expand I might still be wrong! (Nick Kingston) Never worked for me. 3 jaw lathe chuck works best. (Ralph Moon) I have never tried this, but why not assemble the ferrules and tape the female for protection and lightly use the vice grip or other pincer approach to close the female down a little? I'd put a little oil on the male before doing this. (Dave Burley) A three jaw chuck from a lathe or drill works well with this method. (Brian Morrow) Searching the Tips page, I found this entry from the late Darryl Hayashida: "After getting a little overzealous with my lathe fitting a ferrule, I recalled someone writing in about fixing a loose ferrule by filling the male with sand and using a punch and hammer to pack in the sand, expanding out the male. I tried it and it works! Except I had no sand so I used table salt. That worked too, except it packed the salt in hard as cement. But a little warm water under the faucet, and it was all cleared out. Who ever came up with the idea--Good Technique!" Nick: Sir D here giving credit to someone prior, but this must be where the salt substitute comes in. Ralph: You say it didn't work for you or work well? Still, might give it a try. Nothing to lose trying, right? !^) (Bob Brockett) With the 3 jaw chuck method you don't have to take the male ferrule off. If you take it off you might as well cut your losses and put on a new one. The 3 jaw works on the male slide. I couldn't get it to work on the female. (Steve Dugmore) I tried it a couple of times. Both a dismal failure. No matter how hard I pounded .no go. I have a couple of questions. It is the male , is it not? Why worry about the female. #2 Why not get a good ferrule and quit worrying about one that is no good? (Ralph Moon) I used that method once and it worked quite well. With the salt in the bore of the male ferrule and a close fitting ram I gently kept tapping the ram until I had expanded the male's diameter. The expansion was fairly even over the length of the male but the very end (water seal) did not gain much in diameter I then refitted the "oversized" male the female. It's still holding strong. (Mike Monsos) I repair a lot of loose fitting male ferrules. I plate the male with copper/bronze to build the slide portion up to a good fit. Then, I plate the slide portion with nickel/cobalt to the final fit. This finish matches the color of the nickel silver pretty close. The biggest problem I run into, is when the male and or the female is worn more at one end than the other. Then I have to plate the male in steps, to bring up the portion that is the loosest, slightly larger than the smaller diameter portion. This is very time consuming. Sometimes this takes two hours or more just to plate and refit one male ferrule. It's also very time consuming to "repair" the female ferrule after it has been "squeezed" to tighten it up. This is not a great way to fix a loose ferrule, unless they are cheap ferrules that you really don't care about. The best way and the cheapest way is to plate them back up to size, or pay the big buck and replace them with new ferrules. (Dave LeClair)

What do you guys do when:

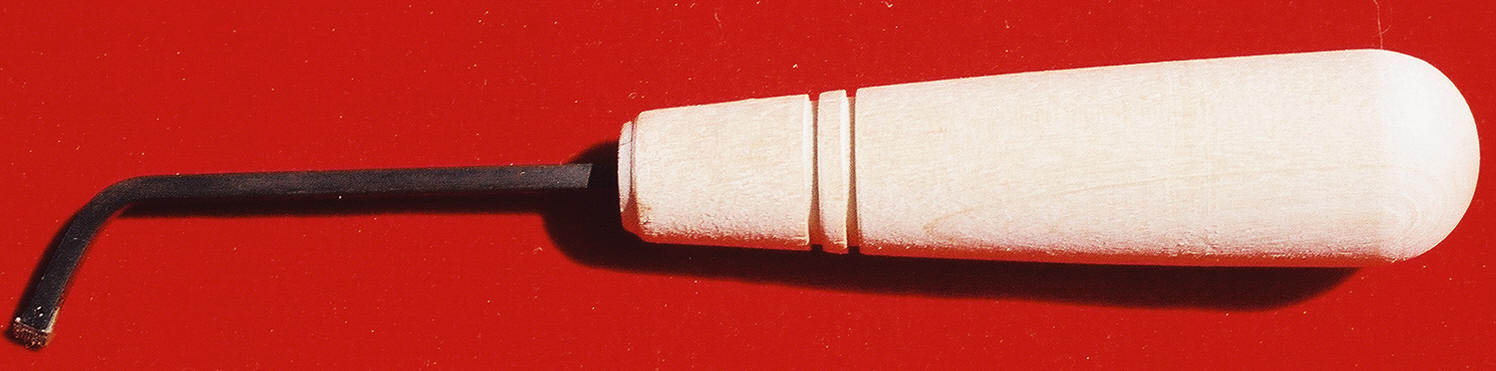

No answer to #1, since I've not had that happen, though it sounds to me that you've lapped the male to a too small diameter. For #2, I use a heat gun on the ferrules, heating them up slightly, just enough to thin the epoxy so that it allows the air bubble to escape a lot easier. Doesn't take too much heat, just enough to make the ferrule feel hot to the touch. (Mark Wendt) I go along with Mark on # 1 On #2, I file a shallow spiral relief groove on the bamboo glue area to relieve the trapped air. I will have to try the heat method on my next rod. (Tony Spezio) I also file a tiny relief groove. I don't like to heat up the epoxy that I use for the ferrules. The small relief groove works just fine in my application. May not with some other glues/epoxies. (Bob Nunley) I also put a small groove in the cane after fitting the ferrule and here's the tool I use works great.

Couple of things, Steve. Most effective for me has been to flick a Bic under the offending ferrule. Heating the ferrule briefly usually allows enough expansion of the metal to let the trapped air out, seen as an epoxy (adhesive) bubble emerging thru the serration tabs. Another method is to scribe a small line the length of the ferrule station to provide an egress route for the air. You may think of it as a narrow, shallow "trench" running the length of the station. Those are my two best options. Keep pushin'! (Steve Yasgur) #1 If the rod is for a customer, replace the male ferrule. You've left no room for future wear. If it's for yourself, put some wax on it. #2 If the ferrule you're using requires you to turn the blank below the level of the flats, file a groove for the glue, or use thinner glue. If possible, or on other rods, for strength, choose a ferrule that will have small portions of the flats remaining when the blank is turned. That way you won't remove all the outer fibers at a critical point on the rod. (Ron Grantham) #1 - It would appear to be overlapped. I purchased a titanium ferrule that was already lapped that did the same thing and I returned it for better fitting ferrule. #2 - George Maurer taught me to put relief grooves in so the air can escape. I've done it two different ways: 1) by using either the pointed end of a triangle file, I drag the file tip along the turned part of the ferrule station making 3 relief grooves that align with 3 alternating flats on a hex. 2) while still mounted in the lathe and with the lathe off, I run the tip of the cutting tool along the ferrule to make the 3 grooves all the while holding the ferrule station from deflecting too much from the lathe tool. (Bob Williams) #1 All those who said the ferrule is too loose- you are correct. I got the ferrule to stay put, but with some vigorous waggling of the rod to test it, the ferrule slowly slides apart. There is no clicking or anything until it is almost completely separated. The fit is darn near perfect but just fractionally too loose. I will replace the male ferrule #2 I used to scratch a line in the bamboo with a scribe but stopped doing it because it didn't always work anyhow. I like the idea of filing a fine groove more carefully. With regard to cutting into power fibers at the ferrule - A design consideration in some of my rods is that using the smallest size super z type ferrule that is appropriate, I design the rod so that the dimension of the bamboo under the female is such that just the very center of the flat remains when the station is turned. I then introduce a small step down in the taper over the ferrule. The bamboo in the male therefore has more of the flat left intact but still has the apexes turned a little to make a snug fit. The ferrule in the case in point was the female of a rod of this sort. I don't believe the strength of the rod is compromised in this way as there are still significant power fibers left intact. (Steve Dugmore) Being that the fit is that close, you should be able to tighten the Female with a large three Jaw chuck by tightening the chuck on one spot. Then rotate the ferrule 1/3 turn, tighten again, do that a few times. I have done this with old ferrules and it works. Be sure the welt is beyond the end of the inner jaws on the chuck as not to damage the welt.. (Tony Spezio) I was reminded that if you have two tips, the idea below post might not work and it would be better to "crimp" the one male. I guess that can be done or just re-fit the second male. You can also do like Dave posted, Chrome the undersized male. I have only done this on old rods that only had one male so I did not give two tips (males) a thought about fitting the second male to the female. (Tony Spezio) I once had a custom rod builder show me another trick for, at least temporarily, tightening a male ferrule. The male was 'clicking' in the mid/butt ferrule on an old Monty. He took a single edged razor blade and cut three score marks pretty well evenly spaced around the slide and for the length of the slide. It definitely had a tighter fit and the clicking stopped immediately. DISCLAiMER: By posting this, I am not endorsing it. (Frank Schlicht) Get a cheap triangle file, a small one, heat it with a torch and bend the end of it slightly so that it's like one of the files or tools that the craftsmen who checker gun stocks use. Makes it really easy to file a controlled groove in the ferrule station. (Bob Nunley) #1 All those who said the ferrule is too loose- you are correct. I got the ferrule to stay put, but with some vigorous waggling of the rod to test it, the ferrule slowly slides apart. There is no clicking or anything until it is almost completely separated. The fit is darn near perfect but just fractionally too loose. I will replace the male ferrule You don't have to replace that male ferrule. I've nickel plated hundreds of loose male ferrules, to bring them back to size. A lot cheaper and a lot less work to do that than to replace and refit another male. But, either way will work. (Dave LeClair)

It seems I am lacking information. I am hand lapping a set of 14/64 ferrules (Duronze) and having troubles. My lack of skill shows as well. I have no lathe; I am using drill bits as hand mandrels to work on the ferrules. I can get both males to such a place where they fit as best as I think I can get, all but the final 1/8 of an inch or so, lengthwise on the depth of the slide. Both seem to have a little bit of a high spot at the part that goes the deepest, the tip, as when I 'try' the fit a few times, that is the spot that gets polished the most. But so far, even dressing that area doesn't seem to help. I am using wet/dry papers to dress with (220, 320, 400 and 600 grit. I know they are probably too course, but it has taken me, probably 20+ hours over 2-3 weeks, to get to this spot as is). In fiddling with the pieces, it seems there is an air lock. I can push the males on about half way and when released, they will separate on their own about half of that, from air compression I expect. I can also, get them such that when on as far as I can get them, you can partially pull them apart and release and they suck partially back on again. In pulling them apart, I get that nice little pop, as is so often described as the goal. I just cannot get that last little bit to go on fully, for either male. In measuring them with calipers, my lack of skills shows. I have low spots in the center of the slide. Probably endemic to my process. The tips measure fine. the middles a bit low/undersized, and the last bit, perhaps a bit big still, not not really so. My calipers can only guess to the 1/2 of 10,000th of an inch. (please no comments about my terrible measuring devices, the actual numbers are really meaningless. it is the relationship between them) Do I need to troubleshoot the female? Could it not be reamed the full depth? I really hesitate even trying to modify that. I have no way of measuring diameter that deep. How would one even consider polishing the deepest part of that hole, without messing up the rest, and therefore ruining the fit I've got now? Is it common to get an air lock, or the fit to be that tight, while sliding in/out like normal? Do I need to just keep dressing them? I hesitate going much further, as I don't want to mess it up. Any thoughts/suggestions? (Sam Nielson) If you can take me, a rookie per se' and coming from hand-fitting only a handful (5-6sets) of ferrules as you describe Here's what I'd try...a suggestion only. The real rod guys here will likely blow this away but here goes.... It is a long and tedious process, Sam, and you would appear to be getting there.These days I have a lathe, Grobet #6 and#8 files, diamond lapping sheet, very fine micron papers and OOOO steel wool, but I fitted dozens by hand before all the fancy stuff came along.In your case I would say "softly, softly catchee monkey," and go slow.Don' waste time trying to measure things - this is a sand-and-try business.I would first of all put a drill bit in your drill and wrap 0000 steel wool aroung it until it is a snug fit, spinning, in the female, and give the female a good polisg out and then a good swabbing with Q-tips and alcohol.Then coat your male with whiteboard marker and try it in the female for fit. You will be able to see where you need to reduce it.Then wrap the non-slide end of the male very evenly and carefully in masking tape (or make a wooden mandrel to hold it firm) and mount that in your drill.Holding the drill in your non-master hand, turn it on and lap with steel wool, using some kind of brass polish (or not, as you prefer).Stop, clean the male carefully and try the fit OFTEN. Keep replacing the whiteboard marker if it helps you to see where you need work.Go slow and careful, and good luck! (Peter McKean) I have to ask firstly is the female drilled and reamed full depth of the male slide? The reamer wont bottom to the end of the drilled hole if there's a bevel on the end of the flutes and that 0.5mm or whatever will stop the slide from bottoming out if it hasn't been drilled deep enough.The vacuum you're experiencing is a good thing. If you're mic'ing these you'll find that a fit is about 0.0005-0.00001 over size (5 ten thousandths) so you're after a very slight interference fit and that's very hard to measure after you've been dressing it because it'll be all over the place along the length of the slide so don't try, just do as Pete suggests and use a Grobert file. A #6 is good. If you can measure accurately try seeing what the part of the slide that fits mics at and attempt to make all of the male slide the same but don't get tense if you can't do this, just use the carbon paper or whiteboard marker and a grobert file and be careful. Be warned though that it sounds as if you're already there and very close in other places and the dif between no fit and loose fit is a single stroke of the file.I'm going to say something that I'm certain will elicit responses such as "I've always done this and it works fine" etc but you really should not use a lapping compound of any kind on bronze.The compound gets into the pores for want of a better term we all know of the bronze and "loads" it microscopically. That's excellent when you're using the bronze to do the lapping but bad when you don't want it to continue lapping which it will no matter how well you think you've cleaned it all up when you've finished and that's bad for a finished ferrule. (Tony Young) Two additional things that might help.First, most ferrules, whether tubing or round stock, are not perfectly round. This goes for the males and females. They'll be really close depending on the capability of the machine and its user, but they will be a hair oval. You might find that the ferrule pairs fit better oriented this way versus that way. I have found it helpful to maintain the orientation by marking witness marks on male and female with a sharpie. Often have to remark as it wipes off. All that was previously written still holds.Second, lots of folks believe it is better to (at least) final fit the ferrules after they are mounted on the blank. You can read through the archives to decide if this is how you want to do it. Consider the above paragraph if you go this route--get them oriented correctly during gluing and then you don't have to worry about it again. (Chris Moore) On the 5 rods I have made so far, I mounted both ferrules on the blank and then started sanding and working male ferrule down. I started with 440, then some 320 and lots of 0000 steel wool in between. I also cleaned the ferrule with acetone often. Main thing is when sanding down male ferrule, when it starts to fit into female ferrule work your way up the butt of ferrule slowly and polish with 0000 steel wool or 5000 sand paper. A couple or three hours and you should have a good fit. Polish, polish and then you will hear that pop when you disassemble... (Lew Boyko)

I make one or two rods per year. I think the learning curve on lapping ferrules can be long. So, I have just two chances per year to further my lapping skills. By the time ferrule lapping time comes around I really haven't retained much of what I learned a year ago. Its like starting over, really. I wasn't getting much better at it over the years. The pre-lapped ferrules I got were way too tight once I mounted them on the rod (to be honest, they wouldn't even go together) which was good. I suspect what happens is that they fit up tight when shipped but once mounted on the bamboo they grow just that little bit which is good. I didn’t need to get out the expensive Gorbet files. I mounted a piece of 2000 grit wet or dry on a flat piece of aluminum about one inch wide. Each time I made a pass, just a smudge of NS came off on the paper. It took very few passes to get a fit I liked and there wasn’t a trace of my trademark taper on the male. Best fitting ferrules on any of my rods. I guess the question might be: Who really gets the "credit" for lapping the ferrules on my rod Wagner, or me? (Right now I feel so...so cheap...tawdry...like I may have betrayed my craft. Can I really claim to be a rodmaker now that this haunting truth is out about me...alas?) (Bruce Morton) This may be an utterly dumb question, and if it is, I apologize to anyone annoyed by it, but why aren't all ferrules pre-lapped? (Charlie Dybus) Because it's almost impossible to lap them to everybody's liking. If you lap them too loose you can't un lap them and if too tight you still have to finish them yourself. It's a skill that as a rodmaker people should learn to do anyhow. It's that hard to do, you just take your time. (Tony Young) It is very time consuming. (Ron Kubica) The other issue with pre-lapped ferrules is once you glue the ferrules onto the blank, they inevitably change size due to the adhesive expanding or contracting as it cures, or the cane expanding or contracting due to its moisture content. That's the main reason I prefer to lap the ferrules once they are on the rod, and the adhesive is cured. (Mark Wendt) Mark is right there. Also, if they're mounted then dressed you have them on the rod they'll be used on. You have the rod sections to hold as you dress the male and you can make sure the fit is exactly as you want. Dressing the male on the lathe is very hard to really tell how it will go on the rod and as Mark wrote, the fit alters once mounted. (Tony Young) This was one of the topics discussed at some length at a 3-day bamboo rod makers' gathering at Cressy, here in Tasmania, and it surprised me to find out how many different approaches there are to take to the task. Personally, I have a set of bamboo mandrels to hold the male and female ferrule components; I then work them down with #6 and#8 Grobet pillar files, a series of fine papers and some OOOO steel wool. Prior to starting on the male, I find it pretty well essential to polish out the female with a wad ot OOOO steel wool mounted on a mandrel held in a Dremel. (Peter McKean)

OK, I have a question. I was given a set of lovely pre-fitted ferrules by a friend but one male is too loose (not me, the ferrule). Short of crimping the female and then sanding down the well-fitting male, what can be done? Thanks. (Tom Lucas) Have the male slide of the loose ferrule nickel plated and refit. (Alex Vardanis) Replate the ferrule. A kit to DIY available from Caswell. If you crimp the female, you’ll have to refit the other male. (Henry Mitchell) Another male? (Tony Young) At last weeks Grayrock gathering Dave Triesenberg gave a presentation on reel seats and reel feet and at the end of the presentation he showed us all slides of a new device that will provide equal pressure via rollers or ball bearings to the female portion of the ferrule. The prototype is said to have worked well and Dave is talking tome shops now for producing to sell. He believes they will sell for under $100.00. I believe you can see the slide depicting the device by going to Dave's latest posting at NorthBranchReels.com. Might not be something that you'll want to invest in for one ferrule but might be a good group purchase. (Greg McGowan)

|

||||||||||||||||||||||